With the advancement of policies promoting waste sorting and resource utilization, the waste screening industry is facing development opportunities, but also challenges due to the complex composition of waste. A large amount of magnetic impurities mixed in waste not only easily cause breakage and wear and jamming of screening equipment, but also reduce the purity of recyclables, hindering the resource recycling process. Against this backdrop, magnetic separators, with their highly efficient iron removal capabilities, have become key equipment in waste screening systems, ensuring equipment safety and improving processing efficiency. This article will delve into the specific applications of magnetic separators in the waste screening industry, providing a reference for equipment configuration within the industry.

In the fields of industrial production and material handling, magnetic separators, as crucial auxiliary equipment, bear the important responsibility of removing magnetic metallic impurities from materials. Their applications cover multiple industries, and their unique performance characteristics provide strong guarantees for production safety, product quality improvement, and equipment protection.

Wide Range of Application Scenarios for Magnetic Separators

The application scenarios of magnetic separators are closely related to their core function of removing magnetic impurities. In different industries, and for different materials and production needs, they exhibit diverse application forms.

1. Application of Magnetic Filters in the Waste Screening Industry

In the waste treatment industry chain, waste screening is a crucial link in achieving resource recovery and harmless treatment. Waste composition is complex, containing large amounts of household waste, industrial scraps, and discarded appliance fragments. Magnetic impurities mixed in, such as iron nails, wires, scrap steel bars, and metal cans, can severely damage screening equipment and affect subsequent resource recovery efficiency. Magnetic filters play an irreplaceable protective and auxiliary role in this scenario.

From an application perspective, magnetic filters are mainly installed in the pre-treatment stage and core screening环节 of the waste screening system. Before entering the screening equipment, waste needs to be conveyed to the crushing equipment for volume reduction. At this time, a permanent magnet suspension magnetic filter is suspended above the conveyor belt. This type of magnetic filter has a stable magnetic field strength and can quickly adsorb magnetic impurities on the surface and shallow layers of the waste, such as iron connectors from discarded furniture and broken steel bars from construction waste. This prevents these hard objects from entering the crusher, preventing wear, jamming, or even shutdown of the crusher's cutter head, and ensuring continuous operation of the crushing process.

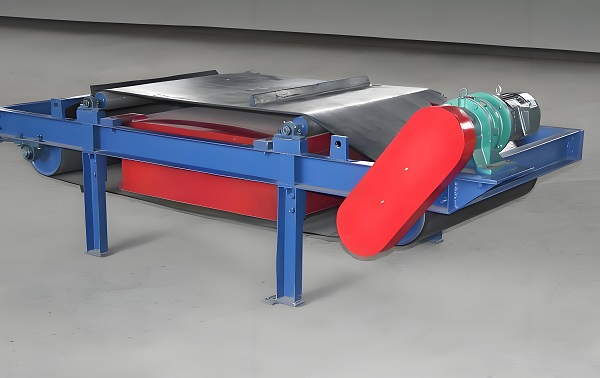

After entering the core screening stage, the waste is crushed into finer particles, and magnetic impurities are more dispersed. At this point, pipe-type or drum-type magnetic separators are installed at the feed inlet or inside screening equipment such as rotary screens and vibrating screens. Pipe-type magnetic separators can be embedded in the waste conveying pipeline to precisely adsorb fine magnetic impurities (such as fragments of discarded battery casings and metal packaging debris) in powdery and granular waste. Drum-type magnetic separators can be combined with the drive drum of the screening equipment. When the waste rolls and is screened on the screen surface, magnetic impurities are adsorbed by the magnetic field on the drum surface and separated from the waste flow with the rotation of the drum, collected by scrapers. This does not affect screening efficiency and avoids impurities scratching the screen, extending the service life of the screening equipment.

The application of magnetic separators in the waste screening industry also contributes to resource recycling. The magnetic metal impurities adsorbed and collected can be directly sent to waste recycling stations after sorting, realizing "turning waste into treasure" and improving the economic efficiency of waste treatment. At the same time, waste with magnetic impurities removed can be more efficiently separated into recyclable materials such as plastics and paper, reducing the impact of impurities on the purity of recycled materials. Furthermore, the magnetic separators used in this scenario typically employ a sealed shell design, which can resist corrosive gases and humid environments generated by waste fermentation, ensuring stable operation under harsh conditions, reducing equipment maintenance frequency, and providing reliable assurance for the efficient operation of the waste screening system.

2. Application of Magnetic Separators in the Power Industry In the power industry, magnetic separators are mainly used in coal conveying systems. Thermal power plants use coal as their primary fuel, and during mining, transportation, and storage, coal is highly susceptible to contamination with magnetic impurities such as iron parts, nails, and wires. If these impurities enter downstream equipment, such as coal mills, they will severely wear down the mill rollers and liners, shortening equipment lifespan and increasing maintenance costs; if they enter the boiler, they may cause slagging inside the furnace, affecting boiler thermal efficiency and even leading to safety accidents. Therefore, suspended or pipeline magnetic separators are typically installed at locations such as coal conveyor belts and raw coal bunker inlets in thermal power plants. Suspended magnetic separators can be directly suspended above the coal conveyor belt. As coal is transported along the belt, magnetic impurities are attracted by the magnetic field generated by the separator, requiring only periodic cleaning. Pipeline magnetic separators, on the other hand, are installed inside the coal conveying pipeline, suitable for enclosed material transport environments. They more efficiently remove magnetic impurities from the coal within the pipeline, ensuring the stable operation of the entire coal conveying system.

3. Applications of Magnetic Separators in the Building Materials Industry

In the building materials industry, magnetic separators are widely used in the production processes of cement, glass, ceramics, and other products. Taking cement production as an example, cement raw materials mainly include limestone, clay, and iron powder. During the mining and crushing of these raw materials, a large amount of metallic impurities are mixed in, such as scrap iron from iron ore and metal fragments generated by crusher wear. If these impurities enter the cement rotary kiln, they will react chemically with the cement raw materials at high temperatures, generating substandard cement clinker, affecting the strength and quality of the cement. Simultaneously, metallic impurities will also wear down the rotary kiln lining, shortening the equipment maintenance cycle. Therefore, magnetic separators are installed at key locations such as the conveyor belts of cement raw materials, the inlet of raw material silos, and the outlet of the crusher. For example, a permanent magnet separator is installed on the conveyor belt after limestone crushing to effectively adsorb magnetic impurities in the raw materials; a pipeline electromagnetic separator is installed in the pipeline before the cement raw meal enters the kiln to further remove residual fine metal impurities, ensuring stable cement production and qualified product quality.

In glass production, metallic impurities in glass raw materials can cause defects such as bubbles and stones in glass products, affecting the transparency and appearance quality of the glass. Therefore, magnetic separators are installed during the mixing and conveying of glass raw materials. Typically, a suspended permanent magnet separator is installed at the outlet of the glass raw material mixer to remove magnetic impurities; a high-precision electromagnetic separator is installed in the conveying pipeline before the raw materials enter the glass melting furnace to further remove fine metal particles, ensuring the normal operation of the glass melting furnace and the quality of the glass products.

Core Characteristics of Magnetic Separators

The widespread application of magnetic separators across multiple industries is inseparable from their unique core characteristics, encompassing performance, structure, and application, meeting the production needs of various sectors.

1. High-Efficiency Magnetic Separation Performance High-efficiency magnetic separation performance is one of the most crucial characteristics of magnetic separators. Both permanent magnet and electromagnetic magnetic separators generate strong magnetic fields with a powerful adsorption capacity for magnetic metallic impurities. Permanent magnet separators utilize high-performance permanent magnet materials, such as neodymium iron boron permanent magnets, which possess high magnetic field strength and depth. This effectively adsorbs magnetic impurities located far from the separator, and the magnetic field exhibits good stability and a long service life. Under normal operating conditions, the magnetic field strength does not significantly decrease, maintaining a consistently high-efficiency magnetic separation effect. For example, permanent magnet separators used in coal conveyor belts can achieve magnetic field strengths exceeding 12,000 Gauss, adsorbing iron pieces with a diameter greater than 5 mm, with an iron removal efficiency exceeding 95%.

Electromagnetic separators generate a magnetic field through an energized coil. The magnetic field strength can be adjusted according to actual needs, offering greater flexibility. For materials containing a large amount of fine magnetic impurities, increasing the current of the electromagnetic separator enhances the magnetic field strength and improves iron removal efficiency. For materials with a low content of magnetic impurities, the current can be appropriately reduced to save energy. For example, in the process of iron removal from cement raw materials, the magnetic field strength of the electromagnetic separator can be adjusted to ensure that the iron removal efficiency remains stable above 98%, effectively removing fine metallic impurities from the raw materials, taking into account the differences in magnetic impurity content between different batches of raw materials.

2. Diverse Structural Forms Iron separators come in various structural forms, allowing selection based on different application scenarios and material conveying methods, greatly improving their applicability. Common iron separator structural forms include suspended, pipe, drum, and drawer types.

Suspended iron separators are mainly used in scenarios involving belt conveyors. They can be directly suspended above the belt without affecting normal material transport, and are easy to install and maintain. Depending on the type of magnetic field, magnetic separators can be divided into permanent magnet suspension separators and electromagnetic suspension separators. Permanent magnet suspension separators are suitable for locations without or with limited power supply, while electromagnetic suspension separators are suitable for scenarios requiring high iron removal efficiency and frequent adjustments to the magnetic field strength.

Pipeline magnetic separators are suitable for environments where materials are transported via pipelines, such as those conveying cement raw materials, coal powder, flour, and other powdery materials. They have a compact structure and can be directly installed in the middle of the pipeline. As the material passes through the pipeline, magnetic impurities are attracted to the magnetic core of the separator, which only needs periodic cleaning. Pipeline magnetic separators offer advantages such as good iron removal efficiency, small footprint, and no impact on material flow rate.

Roller magnetic separators are typically used in conjunction with belt conveyors, with the separator's rollers serving as either the drive or redirecting rollers of the conveyor. When material passes through the rollers with the belt, magnetic impurities are attracted by the magnetic field on the roller surface and carried to a non-magnetic field area by the roller's rotation. The impurities are then scraped off by scrapers, achieving continuous iron removal. Drum-type magnetic separators are suitable for applications requiring continuous and efficient iron removal, such as the conveying and iron removal of bulk materials like coal and ore.

Drawer-type magnetic separators are primarily used in industries with high hygiene requirements, such as food and pharmaceuticals. Their structure resembles a drawer, allowing for easy removal and cleaning of adsorbed impurities. They are simple to operate and effectively prevent secondary contamination of materials by impurities. Drawer-type magnetic separators are typically made of stainless steel, with a smooth surface that is easy to clean and meets food hygiene standards.

3. Good Adaptability and Stability

Magnetic separators exhibit good adaptability and can operate stably under various working environments and conditions. In terms of temperature, ordinary magnetic separators can operate normally in ambient temperatures ranging from -20℃ to 80℃. For high-temperature conditions, such as near cement rotary kilns or glass melting furnaces, high-temperature resistant magnetic separators can be selected. These use high-temperature resistant permanent magnets and insulating materials, maintaining stable iron removal performance in high-temperature environments ranging from 200℃ to 500℃. For example, high-temperature resistant permanent magnet separators used for conveying raw materials in cement rotary kilns can operate continuously at ambient temperatures of 300℃, ensuring the continuity of iron removal.

Regarding humidity, the separators have excellent moisture-proof performance. Their sealed outer shell design effectively prevents moisture from entering the equipment, avoiding damage to internal electrical components or permanent magnet materials. In humid working environments, such as coal washing plants and cleaning workshops in the food processing industry, the separators can operate normally without additional moisture-proof measures.

Furthermore, the stability of the separators is also reflected in their low failure rate during operation. Whether it's a permanent magnet separator or an electromagnetic separator, the core components have a long service life. The permanent magnet material has a service life of over 10 years, and the electromagnetic coil has a service life of over 5 years. At the same time, the separators have a reasonable structural design with few moving parts, requiring minimal maintenance. Only periodic cleaning of adsorbed impurities and simple visual inspection are needed to ensure stable operation, reducing maintenance costs and downtime for enterprises.

4. Environmental Protection and Energy Saving Characteristics With the increasing popularity of environmental protection and energy-saving concepts, separators are also paying more attention to environmental protection and energy-saving characteristics in their design and manufacturing processes. Permanent magnet separators require no electricity during operation, with only minimal labor costs for installation and impurity removal. Compared to electromagnetic separators, they offer significant energy savings. For long-term continuous operation scenarios, such as iron removal on coal conveyor belts, permanent magnet separators can save substantial electricity costs, reducing production costs for enterprises.

While electromagnetic separators do consume electricity, their energy-saving design has been greatly improved. Modern electromagnetic separators utilize high-efficiency core materials and optimized coil structures, reducing copper losses in the coils and iron losses in the core, thus improving energy utilization. Furthermore, some electromagnetic separators are equipped with intelligent control systems that automatically adjust the magnetic field strength and operating time based on the content of magnetic impurities in the material, avoiding unnecessary energy waste. For example, when the content of magnetic impurities in the material is low, the intelligent control system automatically reduces the current of the electromagnetic separator, reducing energy consumption; when the content of magnetic impurities increases, it automatically increases the current to ensure iron removal efficiency.

Furthermore, the materials used in magnetic separators meet environmental protection requirements. Their outer shells are typically made of recyclable steel, and the internal permanent magnets and electrical components can be recycled after disposal, reducing environmental pollution.

Magnetic separators are used in the waste screening industry, covering both pretreatment and core screening stages. Through the combination of different types of equipment, such as permanent magnet suspension, pipeline, and drum types, they effectively remove magnetic impurities of various forms. They not only protect crushing and screening equipment, reducing downtime, but also facilitate the recovery of magnetic metals and the purification of other recyclables, combining equipment protection with economic value. Coupled with a sealed design adapted to harsh working conditions, magnetic separators provide crucial support for efficient and environmentally friendly waste screening, serving as important auxiliary equipment for promoting high-quality development in the industry.

Save Time! Get A Detailed Quotation Quickly.