Foreword: With the continuous advancement of urbanization and the booming development of the construction industry, a massive amount of construction waste is generated. Its resource utilization and harmless treatment have become crucial for practicing green development and alleviating environmental pressure. In the entire process of construction waste treatment, screening is the core link connecting crushing and recycling. Air separators, relying on aerodynamic principles and leveraging their high-efficiency sorting technology, play an irreplaceable role in construction waste screening. They can achieve precise separation of light and heavy materials, helping to improve the utilization rate of recycled resources, reduce pollution, and promote the transformation of the construction waste treatment industry towards high efficiency and environmental protection, laying the foundation for the resource-based development of construction waste.

With the continued acceleration of urbanization and the booming development of the construction industry, a massive amount of construction waste has also been generated. Its resource utilization and harmless treatment have become key issues in addressing environmental pressure and practicing green development. In the entire process of construction waste treatment, screening is the core link connecting crushing and recycling. Air separators, as highly efficient sorting equipment based on aerodynamic principles, play an irreplaceable role in construction waste screening due to their unique technological advantages. They not only achieve precise separation of light and heavy materials but also improve the utilization rate of recyclable resources, reduce environmental pollution, and promote the transformation of the construction waste treatment industry towards high efficiency, environmental protection, and resource utilization.

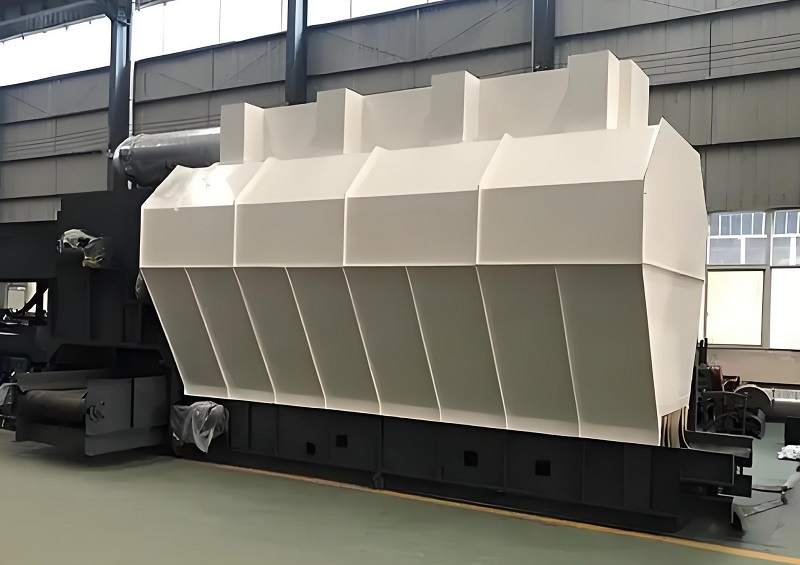

The core function of air separators in construction waste screening is to achieve efficient separation of light impurities from heavy useful materials based on differences in material density. This is also its core advantage over traditional screening equipment. Construction waste has a complex composition. After initial crushing, it still contains heavy useful materials such as concrete blocks, bricks, and steel bars, as well as light impurities such as plastic fragments, wood chips, paper scraps, foam, and textiles. If these light impurities are mixed with heavy materials, they will seriously affect the quality of subsequent recycling. Air separators use fans to generate directional airflow. By adjusting the appropriate wind speed and direction, when a mixture of materials enters the air separator system, lighter impurities with lower density are blown up by the airflow and enter the collection device along a pre-set channel; while heavier materials such as concrete and bricks settle due to gravity and are discharged through the outlet. This achieves precise sorting of light and heavy materials, laying the foundation for subsequent recycling.

Compared to traditional manual sorting and single screening equipment, air separators significantly improve sorting efficiency and accuracy, effectively addressing the pain points of traditional sorting methods. Traditional manual sorting is not only inefficient and has a very limited sorting capacity, but it is also prone to missed sorting due to fatigue, making it difficult to guarantee the removal rate of light materials. It also requires a large investment of labor, and the odors and sharp impurities in the waste seriously threaten the health of workers. Air separators, on the other hand, can achieve continuous automated operation, with a considerable processing capacity, far exceeding the efficiency of manual sorting, and requiring no dedicated personnel, significantly reducing labor input and operating costs. Meanwhile, modern air classifiers are equipped with intelligent control systems and gradient airflow designs, automatically adjusting wind speed according to material characteristics to create different levels of airflow fields. This allows for gradient separation of lightweight impurities of varying densities. For example, high-speed airflow is used for ultralight materials such as foam and thin plastic film, while steady-flow airflow is used for medium-light materials such as thick cardboard and wood chips. The removal rate of lightweight materials is extremely high, significantly reducing the impurity content of recycled aggregates and substantially improving sorting accuracy.

The application of air classifiers effectively improves the utilization rate of recycled resources from construction waste, promoting high-quality development of resource utilization. Heavy materials in construction waste, such as concrete blocks and brick fragments, can be further crushed and screened after air classification to remove lightweight impurities, producing recycled aggregates for use in the preparation of recycled concrete, recycled mortar, and environmentally friendly bricks. Without air classification, lightweight impurities will mix into the recycled aggregates, leading to a decrease in the strength and durability of recycled building materials, failing to meet engineering requirements, and ultimately requiring landfill disposal, resulting in resource waste. Air separators precisely remove lightweight impurities, ensuring the purity and quality stability of recycled aggregates, enabling them to meet relevant industry standards and broadening their application scope. Furthermore, the lightweight impurities separated by air separation can be recycled and reused; for example, waste wood and sawdust can be used for biomass power generation, plastic fragments can be recycled and reprocessed, and paper scraps can be recycled into waste paper, achieving "turning waste into treasure" and improving the overall resource utilization rate of construction waste, practicing the treatment concept of "reduction, resource recovery, and harmlessness."

From an environmental protection perspective, the application of air separators effectively reduces the environmental pollution risks during construction waste treatment, contributing to green and environmentally friendly development. On the one hand, through efficient separation, air separators significantly reduce the total amount of construction waste that needs to be landfilled, alleviating the pressure on land resources. At the same time, they prevent leachate from rainwater infiltration after lightweight impurities are landfilled, which could pollute groundwater and soil, and also reduce air pollution caused by windblown dust during open-air storage. On the other hand, most modern air separators integrate dust removal devices and air circulation systems. They filter fine dust from the return air using cyclone modules, preventing dust accumulation and blockage in the fan, while reducing dust leakage during operation, improving the working environment, and minimizing the impact of dust on the surrounding environment and workers. Practice has shown that air separators offer significant environmental benefits, effectively reducing greenhouse gas emissions and playing a positive role in ecological environmental protection.

Air separators can also optimize the construction waste processing flow, improving the stability and efficiency of the entire production line and reducing overall processing costs. In construction waste processing lines, air separators can be seamlessly integrated after crushers and vibrating screens, forming a continuous "crushing-screening-air separation" process. The crushed and screened materials directly enter the air separator for sorting, eliminating the need for additional transfer and reducing material loss and transportation costs. Furthermore, air separators have a simple structure, are easy to operate, adopt a modular design, are convenient to install and maintain, have minimal wear on parts, and require short downtime, allowing for long-term stable operation and reducing the impact of equipment failures on the production line. Furthermore, air separators have low energy consumption, employing variable frequency motor control that adjusts power according to material throughput. Compared to other sorting equipment, this effectively saves electricity, further reducing overall operating costs for businesses. For example, after introducing an air separator system, a construction waste treatment center saw a significant decrease in labor costs and a substantial increase in the price of recycled aggregates, resulting in considerable economic benefits.

In practical applications, air separators are highly adaptable, handling different types and compositions of construction waste, including demolition waste and renovation waste. They effectively separate various lightweight impurities, meeting the needs of different processing scenarios. Whether dealing with construction waste from new project cleanup or complex mixed waste from urban redevelopment and demolition, air separators can achieve precise sorting by adjusting wind speed and sorting parameters. Simultaneously, with the development of technologies such as the Internet of Things and big data, intelligent air separators have been gradually deployed. These machines use AI vision sensors to scan material characteristics in real time and automatically adjust sorting parameters, further improving sorting accuracy and efficiency, and driving the construction waste treatment industry towards intelligent transformation.

Air separators play a crucial role in construction waste screening. Their core value lies in achieving the dual goals of resource utilization and harmless treatment of construction waste through precise and efficient separation of light and heavy materials. They not only overcome the pain points of traditional sorting methods—low efficiency, poor accuracy, high cost, and significant pollution—but also improve the utilization rate of recycled resources and optimize the processing flow. Furthermore, they bring significant economic and environmental benefits to construction waste treatment companies, promoting the green and sustainable development of the construction industry. With increasingly stringent environmental policies and rising demands for resource utilization, air separators, as core equipment in construction waste screening, will see their application scope continuously expand and their technology continuously upgraded, providing strong support for turning construction waste into "urban minerals" and contributing to the construction of a beautiful China.

Air separators play a core role in construction waste screening, effectively overcoming the pain points of low efficiency and poor accuracy in traditional sorting by precisely separating light impurities from heavy useful materials. Their application not only significantly improves the utilization rate of recycled resources from construction waste and broadens the application range of recycled aggregates, but also reduces environmental pollution and the overall treatment costs for enterprises, achieving a win-win situation for both economic and environmental benefits. With tightening environmental policies and technological upgrades, the application scope of air separators will continue to expand, continuously promoting the green and sustainable development of the construction industry and providing strong support for the resource utilization of construction waste.

Save Time! Get A Detailed Quotation Quickly.