Foreword: With the acceleration of urbanization and the improvement of residents' living standards, the amount of municipal solid waste generated continues to increase, and its composition is becoming increasingly complex. Its harmless, reduced-volume, and resource-oriented disposal has become an important task for protecting the ecological environment and promoting green development. As the core link in municipal solid waste treatment, the screening system undertakes the key responsibilities of waste sorting, quality improvement, and diversion, and is an important bridge connecting waste collection and subsequent treatment (incineration, landfill, and recycling). The municipal solid waste screening system is composed of multiple functional modules working collaboratively. Each component has a clear division of labor and works closely together, while possessing distinct characteristics such as strong adaptability, high automation, and outstanding environmental protection, providing strong support for the efficient treatment of various types of municipal solid waste.

The municipal solid waste screening system is not a single piece of equipment, but a complete system composed of a pretreatment unit, a core screening unit, auxiliary units, and a post-treatment unit. Each unit performs its own function and operates collaboratively to ensure that the screening process is efficient and orderly, meeting the treatment needs of different types of municipal solid waste. The pretreatment unit is the foundation of the screening system, primarily used to remove large pieces of debris from municipal solid waste, reduce its moisture content, and loosen any sticky materials. This clears obstacles for subsequent screening operations, preventing large pieces from damaging equipment and affecting screening accuracy. The pretreatment unit mainly includes a feeding device, crushing equipment, and dewatering equipment. The feeding device ensures uniform transport of municipal solid waste, the crushing equipment breaks down large pieces of waste (such as discarded furniture and large packaging items) to a suitable particle size, and the dewatering equipment reduces free moisture in the waste, preventing material from sticking and clogging the screening equipment.

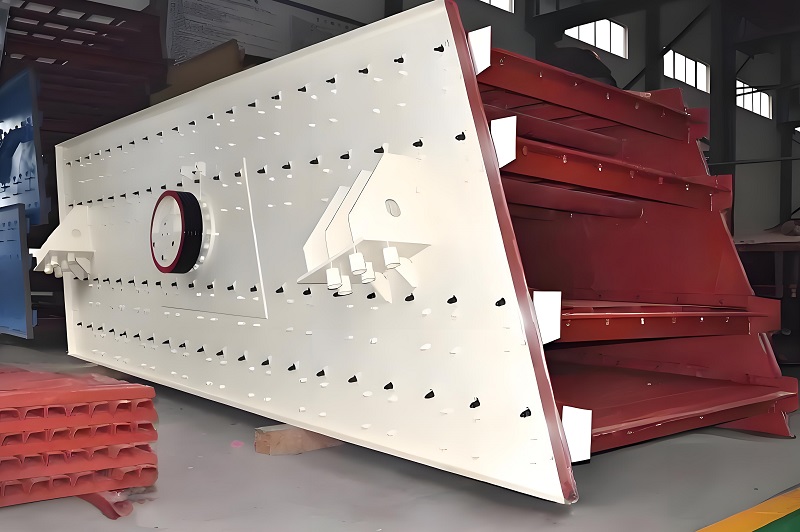

The core screening unit is the core component of the entire system, undertaking the crucial task of accurate waste sorting. Based on the differences in particle size, density, and shape of municipal solid waste, it uses a combination of various screening devices to separate the waste into different components, providing the conditions for subsequent sorting and processing. The core screening unit uses a variety of equipment types to adapt to different screening needs, mainly including vibrating screens, drum screens, air separators, and magnetic separators. Vibrating screens are primarily used to separate waste by particle size, separating fine particles (such as dust and humus) from coarse particles (such as sand and gravel, and plastic blocks). Rotary drum screens use rotating drums to classify waste of different particle sizes, suitable for municipal solid waste with high moisture content and a tendency to clump together. Air separators separate lightweight materials (such as plastic film and paper scraps) from heavy materials (such as metals and sand) based on differences in material density. Magnetic separators are mainly used to separate magnetic metals (such as iron nails and scrap iron wire) from waste, enabling the recovery of metal resources.

Auxiliary units are crucial for the stable operation of the municipal solid waste screening system. Although they do not directly participate in waste screening, they effectively improve system efficiency, reduce equipment wear and tear, and minimize environmental pollution. Auxiliary units mainly include conveying equipment, dust removal equipment, noise reduction equipment, and a control system. Conveying equipment (such as belt conveyors and screw conveyors) runs throughout the entire screening process, ensuring smooth material transfer between units and preventing material accumulation. Dust removal equipment (such as bag filters and cyclone dust collectors) collects dust generated during screening, preventing dust leakage that pollutes the atmosphere and harms workers' health. Noise reduction equipment reduces noise generated during equipment operation through sound insulation and vibration damping, minimizing its impact on the surrounding environment. The control system employs an intelligent design, enabling automated control of the entire screening system, real-time monitoring of equipment operating status, and adjustment of screening parameters to ensure stable and efficient system operation, while also facilitating equipment maintenance and troubleshooting.

The post-processing unit is the final stage of the screening system, primarily used for preliminary sorting and collection of different waste components after screening, providing qualified raw materials for subsequent processing steps. The post-processing unit mainly includes a material collection device, a sorting platform, and temporary storage facilities. The collection device collects the different components of the screened waste separately. The sorting platform is used for manual-assisted sorting to remove impurities missed during the screening process, improving the purity of the waste components. The temporary storage facilities are used to temporarily store the screened waste to avoid secondary pollution and facilitate subsequent transfer to incineration plants, landfills, or recycling companies, achieving the diversion, disposal, and resource utilization of municipal solid waste.

The municipal solid waste screening system, with its scientifically designed components, features strong adaptability, high automation, high screening accuracy, and outstanding environmental protection, efficiently handling the processing needs of various types of municipal solid waste. Strong adaptability is one of its core characteristics. Municipal solid waste has a complex composition, including kitchen waste, plastics, metals, paper, sand, and gravel, and the composition varies significantly across different regions and seasons. Through the combined application of various equipment and parameter adjustments, the screening system can flexibly adapt to municipal solid waste with different compositions and moisture contents, achieving efficient screening without frequent equipment changes.

High automation is a key advantage of municipal solid waste screening systems. Compared to traditional manual sorting, modern screening systems employ a fully automated design, automating the entire process from feeding, crushing, and screening to material collection and transfer, eliminating the need for extensive manual intervention. This not only significantly improves screening efficiency and avoids the subjectivity and fatigue of manual sorting but also reduces direct contact between workers and waste, mitigating the health risks posed by hazardous substances in the waste. Furthermore, it lowers labor costs and enhances the standardization of the entire processing flow.

High screening accuracy is a crucial feature of screening systems, directly determining the effectiveness of subsequent waste treatment and the value of resource utilization. The system, through a rational combination of equipment such as vibrating screens, drum screens, and air separators, and with intelligent parameter adjustment, can accurately distinguish waste components of different particle sizes and densities. It effectively separates fine particles from coarse particles, lightweight materials from heavy materials, and magnetic metals from non-magnetic materials, achieving a high level of screening accuracy. This significantly improves the efficiency and quality of subsequent incineration, landfill, and recycling. For example, it can precisely separate suitable lightweight combustible materials for incineration, improving incineration efficiency and reducing pollutant emissions.

Outstanding environmental friendliness is a prominent feature of the municipal solid waste screening system, aligning with the concept of green and environmentally friendly development. The system is designed and operated with environmental pollution control in mind, equipped with comprehensive dust removal, noise reduction, and dehydration equipment. This effectively reduces dust, noise, and wastewater generation during screening, preventing secondary pollution to surrounding soil, water, and air. Simultaneously, through precise screening, it achieves the diversion and disposal of municipal solid waste, significantly reducing the total amount of landfill waste, alleviating pressure on land resources, promoting the recycling of more waste components, and practicing the treatment philosophy of "reduction, resource recovery, and harmlessness," achieving a win-win situation for both economic and environmental benefits.

The municipal solid waste screening system is a complete system composed of pretreatment, core screening, auxiliary, and post-treatment units. Each unit has a clear division of labor and operates collaboratively, forming a highly efficient waste screening production line. This system features strong adaptability, high automation, high screening accuracy, and outstanding environmental performance. It can effectively handle complex municipal solid waste, achieving precise classification and diversion, laying a solid foundation for subsequent incineration, landfill, and recycling processes. With the increasing demand for municipal solid waste treatment and the continuous upgrading of technology, screening systems will become more intelligent, efficient, and environmentally friendly, continuously promoting the improvement of the resource utilization level of municipal solid waste and contributing to ecological environmental protection and sustainable urban development.

Save Time! Get A Detailed Quotation Quickly.