In the recycling process of construction waste, screening is the core step following the crushing process, directly determining the grading accuracy, purity, and application value of recycled aggregates. The composition of crushed construction waste remains complex, containing concrete particles of different sizes, brick fragments, small amounts of impurities, and large, incompletely crushed materials. Specialized screening equipment is needed for precise grading and impurity removal to obtain recycled aggregates suitable for different scenarios, achieving efficient resource utilization of construction waste. Currently, the resource utilization rate of construction waste in my country is gradually increasing, and screening equipment, as a key supporting equipment, has formed a product system with various types to meet different needs. This article will detail the structural characteristics, working principles, applicable scenarios, and industry applications of mainstream screening equipment after construction waste crushing, providing a reference for relevant practitioners to select equipment and optimize processing procedures, and contributing to the high-quality development of the construction waste recycling industry.

The core function of screening equipment after construction waste crushing is to grade and screen materials according to particle size, remove impurities, separate unqualified materials, and provide standardized raw materials for downstream recycling. Compared to ordinary screening equipment, construction waste screening equipment needs to be wear-resistant, clog-resistant, and adaptable to high-impurity materials. It must be able to handle the uneven hardness, high dust content, and tendency to agglomerate of crushed construction waste, while also meeting the grading requirements for different particle sizes and adapting to the application standards of recycled aggregates in various scenarios such as road construction, concrete mixing, and foundation backfilling. Based on differences in structural form, working principle, and application scenarios, the mainstream construction waste screening equipment in the industry is currently divided into two main categories: vibrating screens and drum screens. In addition, there are specialized models such as high-frequency screens and probability screening equipment, each with unique advantages, covering screening operations of different scales and needs.

Vibrating screens are the most widely used type of equipment in the screening of crushed construction waste. With their high screening efficiency, accurate grading, and strong adaptability, they occupy more than 80% of the market share in the construction waste screening field and are widely used in large and medium-sized construction waste resource utilization centers, adapting to the subsequent screening needs of various crushing equipment. Its core working principle is to utilize the high-frequency vibration generated by a vibrating motor to convey the crushed mixture to the screen surface. The vibration of the screen surface causes materials of different particle sizes to stratify. Materials smaller than the screen openings pass through the screen surface and are classified, while unqualified materials larger than the screen openings are conveyed to the return port and returned to the crushing equipment for re-crushing, forming a closed-loop process of "crushing-screening-return crushing," ensuring that the recycled aggregate particle size meets the standards.

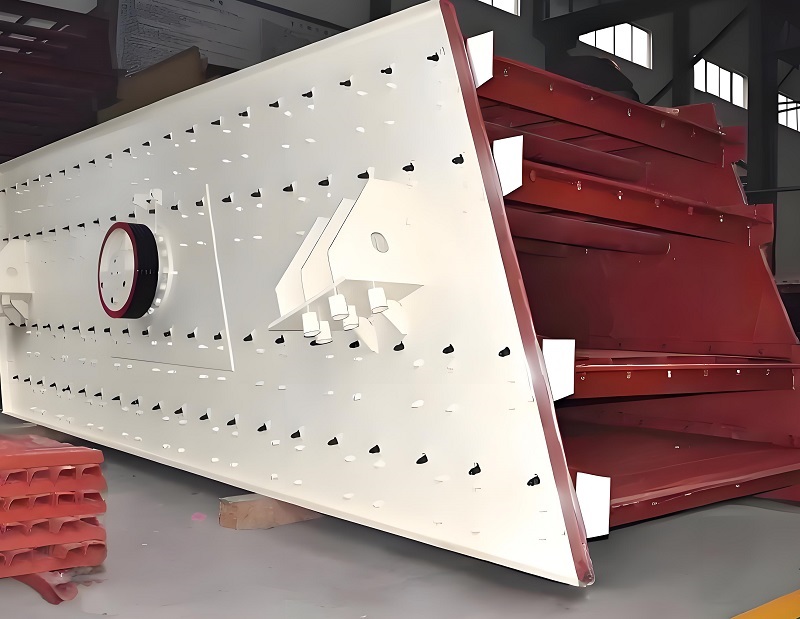

The main sub-types of vibrating screening equipment are linear vibrating screens and circular vibrating screens. These two types differ significantly in structural design, vibration mode, and applicable scenarios, allowing for flexible selection based on the type of material to be crushed and the grading requirements. Linear vibrating screens are driven by dual vibrating motors, with the screen surface vibrating linearly in a reciprocating motion. The material moves at a uniform speed along a straight line on the screen surface, resulting in a stable screening trajectory. This is suitable for scenarios requiring high grading accuracy, such as the production of recycled concrete aggregate and high-quality construction sand. The screen surface of this equipment can be designed with multiple layers (usually 2-4 layers) according to requirements, with different screen aperture sizes in each layer. It can simultaneously classify multiple particle sizes, producing recycled aggregates of different specifications such as 0-5mm, 5-10mm, 10-20mm, and 20-40mm, meeting the personalized needs of various downstream industries.

The screen surface of the linear vibrating screen is made of wear-resistant rubber or polyurethane material, offering strong wear and impact resistance, effectively extending the equipment's service life. It also features an anti-clogging design, capable of handling easily agglomerated materials such as soil and dust contained in crushed construction waste, preventing screen aperture blockage and ensuring screening efficiency. Currently, mainstream linear vibrating screens have a processing capacity of 50-800t/h, a screening efficiency of over 90%, and a grading accuracy error of no more than 3%, making them suitable for large-scale, high-intensity screening operations. The Cixi Construction Waste Recycling Center in Zhejiang Province has introduced multiple large linear vibrating screens, used in conjunction with jaw crushers and impact crushers, to achieve integrated crushing and screening operations. It processes over 1.4 million tons of construction waste annually, and the resulting recycled aggregates of various specifications are widely used in local road subbase and concrete mixing projects, realizing resource recycling.

The circular vibrating screen is driven by a single vibrating motor. The screen body vibrates in a circular motion, and the material undergoes a projectile motion on the screen surface. It has a wide screening range and large processing capacity, suitable for scenarios with moderate grading accuracy requirements and high impurity content, such as primary screening of construction waste and grading of mixed aggregates. This equipment has a compact structure, small footprint, and is easy to install and debug. It can be flexibly combined with fixed or mobile crushing equipment, making it particularly suitable for small and medium-sized construction waste disposal projects. The screen angle of the circular vibrating screen can be flexibly adjusted according to the material characteristics, ranging from 15° to 25°. Adjustment can effectively increase the material screening speed, reduce material accumulation on the screen surface, and further improve screening efficiency.

Compared to linear vibrating screens, circular vibrating screens offer stronger anti-clogging performance, enabling them to handle crushed materials with high mud content. They also boast stable operation, low failure rate, and relatively low maintenance costs, making them suitable for long-term continuous operation. Their processing capacity ranges from 30-600 t/h, with screening efficiency exceeding 85%. They can be designed with single, double, or multi-layer screens to achieve grading of different particle sizes. At demolition sites in old urban residential areas, mobile crushing equipment paired with small circular vibrating screens can achieve on-site crushing and screening. The resulting recycled aggregate can be directly used for foundation backfilling, significantly reducing transportation costs and environmental pollution while improving disposal efficiency.

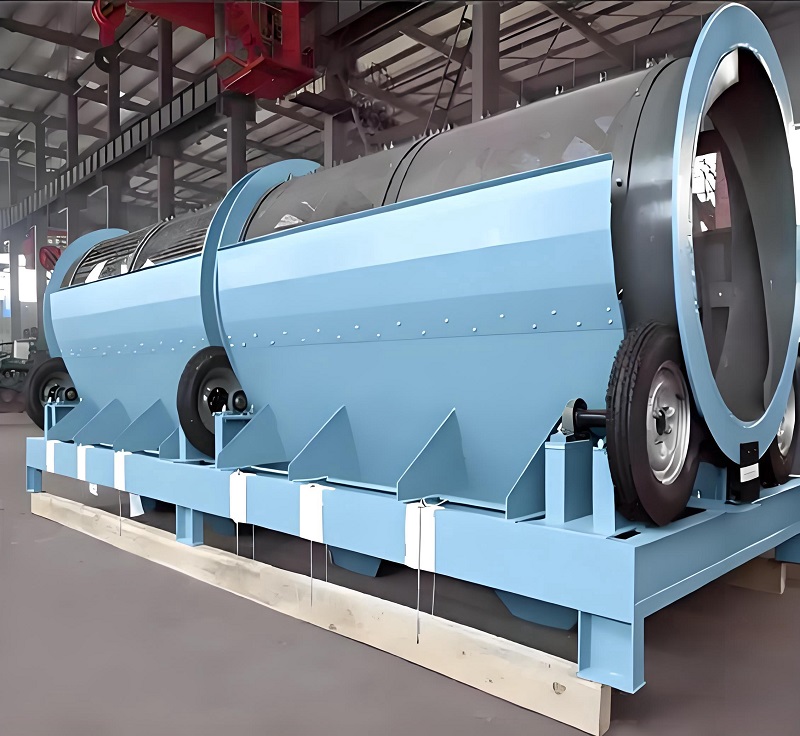

Drum screening equipment is a core model for handling the screening of high-impurity, easily agglomerated construction waste. With its strong anti-clogging capabilities and wide adaptability, it is widely used in screening decoration waste, construction waste with high mud content, and mixed materials. Its core structure is an inclined rotating drum with multiple layers of screens of different sizes inside. The screen aperture gradually decreases from the feed end to the discharge end. The crushed mixture enters the drum from the feed end. As the drum rotates, the material moves along the drum's axis under gravity. During this process, materials of different particle sizes pass through their corresponding screens for grading, while impurities and large pieces are discharged from the discharge end, achieving the dual effects of grading and impurity removal.

The biggest advantage of drum screening equipment is its outstanding anti-clogging performance. Because the drum rotates continuously, the material tumbles inside, making it less prone to clumping and clogging on the screen surface. Even when processing construction waste with a mud content of over 15%, it maintains stable screening efficiency. Furthermore, this equipment is highly adaptable to various materials, handling crushed materials with a particle size range of 0-300mm. Whether it's concrete blocks, brick fragments, or lightweight materials such as mixed plastics and wood, all can be separated through screening, further improving the purity of recycled aggregates. Rotary drum screens are simple in structure, operate stably, and produce low noise and dust, meeting modern environmental protection requirements. They are also easy to maintain; simply checking screen wear and replacing the screens regularly ensures long-term stable operation.

Depending on the installation method, rotary drum screens can be divided into fixed and mobile types. Fixed rotary drum screens are mainly used in centralized processing centers, working in conjunction with fixed crushing equipment. They offer high throughput and stable screening, with a processing capacity of 50-500 t/h, suitable for large-scale, routine screening operations. Mobile rotary drum screens, on the other hand, are vehicle-mounted and can be flexibly moved to the work site. Combined with mobile crushing equipment, they achieve "on-site crushing, on-site screening, and on-site utilization," making them particularly suitable for decentralized, temporary construction waste disposal scenarios, such as road repairs and small-scale demolition projects. Their processing capacity can reach 30-300 t/h, requiring no prior site construction and can be quickly put into use after commissioning, significantly improving processing flexibility.

In addition to the above-mentioned mainstream models, specialized screening equipment is also used in construction waste crushing and screening operations to compensate for the limitations of conventional models. High-frequency screening equipment utilizes high-frequency vibration technology, with vibration frequencies reaching 1500-3000 r/min. This allows for rapid separation of fine powder and dust from materials, improving the purity of recycled aggregates. It is suitable for applications requiring high precision, such as the production of high-end recycled mortar and recycled concrete aggregates. Probability screening equipment, on the other hand, leverages the probability distribution characteristics of material particles. Through inclined screen surfaces and high-frequency vibration, it achieves rapid separation of materials of different particle sizes, offering high screening efficiency and large throughput. It is suitable for large-scale, coarse-grading screening operations, effectively improving the overall efficiency of the processing flow.

With increasingly stringent environmental policies and the iterative upgrading of construction waste resource utilization technologies, screening equipment is developing towards intelligence, environmental friendliness, and modularity. New screening equipment is generally equipped with dust collection systems and noise reduction devices, effectively controlling dust and noise pollution during operation and meeting green production requirements. The application of intelligent control systems enables remote monitoring, parameter adjustment, and fault warning functions for the screening equipment. Operators can precisely adjust parameters such as vibration frequency and screen angle according to material characteristics and grading requirements, significantly improving screening accuracy and efficiency while reducing manual labor intensity. The fully enclosed resource recycling production line for construction waste screening systems incorporates advanced intelligent vibrating screening equipment. A PLC control system automatically adjusts screening parameters, and a spray dust suppression system ensures dust-free screening operations. This system processes up to 600,000 tons of construction waste annually, achieving a recycling aggregate screening accuracy of over 95% and a resource utilization rate exceeding 88%, achieving a win-win situation for both environmental protection and economic benefits. Furthermore, the modular design of the screening equipment allows for flexible combinations of different models and screen specifications based on processing scale and needs, adapting to various screening scenarios, reducing equipment investment costs, and enhancing the equipment's versatility and flexibility.

As an indispensable key piece of equipment after construction waste crushing, the performance and selection of screening equipment directly affect the quality of recycled aggregate and the efficiency of resource utilization. Vibrating screening equipment, drum screening equipment, and various specialized screening equipment each possess unique advantages and applicable scenarios, collectively forming a comprehensive construction waste screening system covering the entire process and all needs. By rationally selecting screening equipment and optimizing screening processes, we can not only improve the grading accuracy and purity of recycled aggregates and expand their application scope, but also reduce disposal costs, reduce environmental pollution, promote the high-quality development of the construction waste resource utilization industry, and help achieve the "dual carbon" goals and build green cities.

Save Time! Get A Detailed Quotation Quickly.