Overview: Eddy current separator is an efficient equipment for sorting non-ferrous metals using the principle of electromagnetic induction. It has the advantages of excellent sorting effect, strong adaptability, reliable mechanical structure, light structure, strong repulsion (adjustable), high sorting efficiency and large processing capacity. It plays a vital role in garbage sorting, especially in the solid waste recycling industry. The following are the applications, structures and characteristics of eddy current separators:

A. Application of eddy current separators:

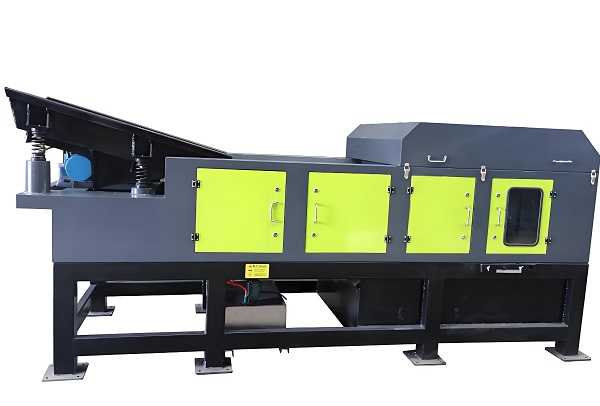

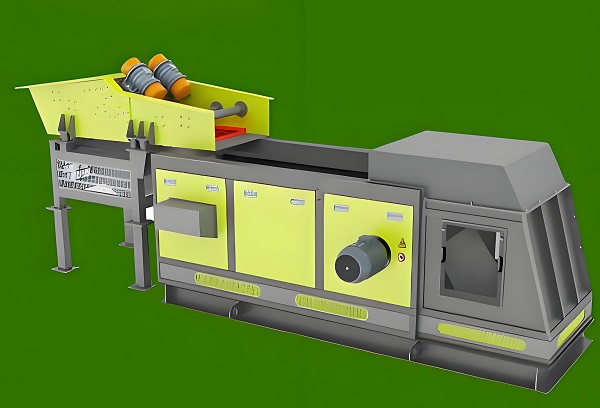

Eddy current separator

1. Eddy current separators are mainly used to recover copper, aluminum and other non-ferrous metals from domestic garbage, industrial waste, electronic waste, glass scraps, waste plastic doors and windows, boiler bottom ash, and waste car slices. It can be widely used in environmental protection fields such as garbage disposal and waste electrical appliance recycling, as well as material processing in non-ferrous metal processing industries.

2. Eddy current separators are named according to the fact that they work on the principle of eddy current. This is a purely physical solid waste sorting method that utilizes the characteristics of non-ferrous metals, and the sorting efficiency has been significantly improved compared to traditional sorting methods. Depending on the material, its sorting efficiency is about 98%. Eddy current separator is a device used for solid waste sorting.

3. Eddy current separator can sort out non-ferrous metals from domestic solid waste or industrial tailings, and is mainly used for the recycling of waste copper, aluminum, zinc and other metals. Such as metals in household appliance crushing materials, metals in automobile crushing materials, crushed materials of circuit boards, sorting of glass bottle aluminum caps, sorting of combustion slag, copper and aluminum cables, ores, etc. for effective sorting.

B. Structure of eddy current separator:

Eddy current separator

The eddy current separator consists of two parts: the separator body and the control cabinet; the main part mainly includes the selection assembly, drive motor, frame and cover. The sorting assembly is the core component of the equipment, which consists of a permanent magnetic roller and a material conveying system (including material conveyor belt, conveyor belt drive roller and reduction motor).

It mainly uses the principle of magnetic roller to produce opposite repulsive force with metal. The action of this repulsive force will produce a forward pushing force on the metal material, which separates the metal from the non-metallic material.

C. Technical advantages of eddy current separator:

Eddy current separator

1. Eccentric magnetic roller design: effectively prevent magnetic particles from entering between the magnetic roller and the belt to avoid scratching the belt;

2. Leading non-leakage magnetic system design: ensure higher metal recovery rate;

3. Unique belt inclination design: effectively prevent non-ferrous metal rebound and improve metal recovery rate;

4. Intelligent centralized lubrication system: automatically set the oil filling cycle to ensure long-term stable operation of each bearing;

5. Comprehensive safety guarantee: installed monitoring and alarm system to monitor the operation of each key component in real time;

6. Intelligent touch control system: one-button start of the equipment, simple operation; can provide real-time feedback of key components and operating parameters;

7. Select SEW motor imported from Germany, stable and reliable, low noise;

8. Select imported bearings, long service life, low noise;

9. Select high-quality German belts, durable.

D. Features of Zhongcheng Machinery Eddy Current Separator:

Eddy current separator

1. The equipment adopts eccentric magnetic roller, which can effectively prevent magnetic particles from entering the surface of the magnetic roller and effectively protect the magnetic roller and running belt;

2. The parts are relatively light, the surface area of the material is relatively small, and the separation effect is excellent;

3. It adopts intelligent touch control cabinet system and frequency conversion control, and the operation is more stable and reliable;

4. The magnetic roller adopts effective magnetic system protection to prevent the magnetic system from falling off;

5. The equipment adopts special technology, precision, low equipment operation time and low noise.

Eddy current separator

PS: As an efficient and environmentally friendly non-ferrous metal sorting equipment, the eddy current separator plays an increasingly important role in garbage sorting. It not only improves the recycling rate of resources and reduces environmental pollution, but also provides strong support for the sustainable development of related industries. In the future, with the continuous advancement of technology and the continuous expansion of applications, eddy current separators are expected to be applied and promoted in more fields.

Save Time! Get A Detailed Quotation Quickly.