Overview: Eddy current separation is an effective method for recycling nonferrous metals. It has the advantages of excellent separation effect, strong adaptability, reliable mechanical structure, light structure, strong repulsion (adjustable), high separation efficiency and large processing capacity. It can separate some nonferrous metals from electronic waste. In the electronic waste recycling and processing production line, it is mainly used to separate non-ferrous metals such as copper and aluminum from mixed materials. It can also be promoted and applied in the field of environmental protection, especially in the non-ferrous metal recycling industry.

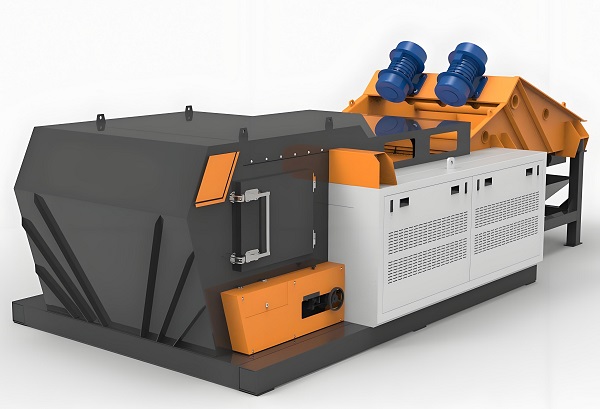

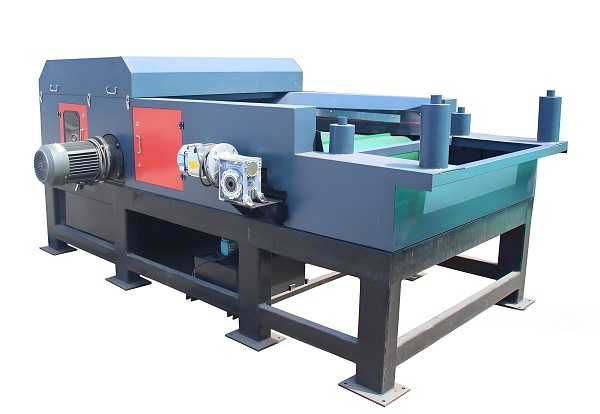

Eddy current separator

A. Working principle of eddy current separator:

When electronic waste scraps containing non-magnetic conductive metals (such as lead, copper, zinc, etc.) pass through an alternating magnetic field at a certain speed, these non-magnetic conductive gold scraps will generate induced eddy currents. Because the material flow and the magnetic field have a relative motion speed, there is a thrust on the metal pieces and blocks that generate eddy currents. Using this principle, some non-ferrous metals can be separated from the mixed material flow. The thrust acting on the metal depends on the size, shape and irregularity of the metal pieces and blocks. The direction of the separation thrust is 90° to the direction of the magnetic field and the direction of the material flow.

The non-ferrous metal eddy current separator consists of a magnetic roller, a conveyor belt, a drive roller, a main frame and other parts. The high-speed rotation of the magnetic roller generates a high-frequency alternating magnetic field, which can induce eddy currents inside the non-ferrous metals. The magnetic field generated by this eddy current is opposite to the original magnetic field. The non-ferrous metals will jump out along the conveyor belt due to the opposite force, thus achieving the purpose of separation.

The physical basis of the eddy current separator is based on two important physical phenomena: an alternating magnetic field that changes with time is always accompanied by an alternating electric field; a current-carrying conductor generates a magnetic field. Therefore, if a conductor is exposed to an alternating magnetic field, or an alternating magnetic field formed by the rotation of a fixed magnetic field, an eddy current perpendicular to the alternating magnetic field flux will be generated in the conductor.

On the other hand, the mirror image magnetic field caused by the conductor eddy current, which is opposite to the induced magnetic field, produces a repulsive force on the conductor. For example, copper and aluminum will leap forward along the conveying direction due to the repulsive force of the magnetic field, and achieve separation from other non-metallic materials to achieve the purpose of sorting. The main distinguishing criterion is the ratio of the conductivity and density of the material. The material with a high ratio is easier to separate than the material with a low ratio. The conductor is separated from the material.

Eddy current separator

B. Classification and characteristics of eddy current separators:

Eddy current separators are divided into concentric and eccentric types. They are equipment for separating non-ferrous metals, copper, aluminum, zinc, iron, and magnesium in crushed mixed materials. The eccentric eddy current metal separator uses an eccentric magnetic machine. The eddy current drum has an eccentric magnetic machine built in, so that the magnetic field changes are concentrated in the area where the material is subjected to concentrated force. In traditional concentric eddy current separators, the magnetic field often appears too early, making it impossible to sort the material. In contrast, the eccentric magnetic machine can not only make the magnetic field large instantaneously when the sorting occurs, but also make the other positions of the head drum have no magnetic field. In this way, no residual nonferrous metal will rotate with the belt head roller, otherwise it will cause serious wear on the belt and roller. This is another aspect in which the eccentric magnetic machine is superior to the concentric magnetic machine.

Eddy current separator

C. Technical advantages of Zhongcheng Machinery's eddy current separator:

1. It is suitable for materials with harsh conditions and small material particle size. The effective separation angle of the magnetic system is 60°, the separation area is larger, and the separation effect is better.

2. The magnetic system adopts high remanence and high coercivity materials, and has an anti-demagnetization ability of no more than 1% in ten years. Reliable magnetic system filling technology solutions and stable magnetic system protection can achieve lifetime maintenance-free.

3. The small and medium components of the main frame are processed separately, and the whole machine has a building block assembly structure to reduce welding deformation, resist vibration, and facilitate maintenance.

4. The bearing seat is specially processed with heat sinks to reduce the bearing temperature rise and extend the bearing life.

5. The rear cleaning roller mechanism continuously cleans the adhesive on the belt surface to improve the separation effect.

6. The magnetic roller bearing seat is equipped with a centralized lubrication system to ensure reliable and stable operation of the equipment.

7. Both the belt roller motor and the magnetic roller motor are imported motors.

8. It has the advantages of simple operation and high degree of automation. It is equipped with fault and failure indication and fault start-stop function, which can protect and repair the equipment in time.

9. The magnetic system of the eddy current separator adopts NN and SS interlaced arrangement, and uses high-performance NdFeB as magnetic material, which makes the magnetic field intensity higher, the action gradient larger, and the sorting effect better.

10. The speed of the magnetic roller and the belt speed of the sorting belt can be adjusted according to the volume, conductivity and other factors of the selected material through the adjustment of the frequency conversion speed regulation device and the position adjustment of the sorting plate to achieve the sorting of various materials and achieve better sorting effect.

Eddy current separator

D. The role and significance of eddy current separator

Eddy current separator is an advanced sorting equipment, which is mainly used to separate valuable non-ferrous metals such as aluminum, copper, zinc, etc. from waste materials. The following are the main functions of eddy current separator:

1. Non-ferrous metal recovery

The eddy current separator can effectively recover non-ferrous metals from various waste materials through the law of electromagnetic induction and eddy current effect. When materials containing non-ferrous metals pass through a high-speed rotating magnetic field, an induced eddy current will be generated inside the non-ferrous metal. This eddy current interacts with the external magnetic field to generate a repulsive force, causing the non-ferrous metal to be ejected from the material flow, thereby achieving separation from other materials. This feature makes the eddy current separator have a wide range of application prospects in the field of metal recycling, especially in the treatment of waste electronic waste, industrial waste, domestic waste, etc., it can efficiently recover non-ferrous metals such as copper and aluminum.

2. Improve resource utilization efficiency

The eddy current separator not only improves the efficiency of metal recycling, but also significantly improves the efficiency of resource utilization. Through precise sorting, non-ferrous metals with higher purity can be obtained, which can be further processed and utilized, reducing dependence on primary metal resources. At the same time, the use of eddy current separators also reduces waste emissions, which helps to achieve resource recycling and sustainable development.

3. Environmental protection and economic benefits

The application of eddy current separators also brings significant environmental and economic benefits. On the one hand, by reducing waste emissions, eddy current separators help to reduce pollution to the environment; on the other hand, recycled non-ferrous metals can re-enter the market and create economic benefits for enterprises. In addition, the eddy current separator has a relatively low operating cost and is easy to maintain, which also provides strong support for its wide application in the field of metal recycling.

Technical parameter table of eddy current separator:

| Category | Model | Overall dimensions | Number of magnetic roller revolutions (1/min) | Processing width (mm) | Motor power (kW) | Weight (kg) | |||

| A | B | C | For conveyor belt | For roller | |||||

| Standard Model | ZCES345S | 450 | 570 | 970 | Max. 3000 (Inverter Variable) | 450 | 1.5 | 3.5 | 1400 |

| ZCES360S | 600 | 750 | 1170 | 600 | 1.5 | 3.5 | 1500 | ||

| ZCES375S | 750 | 900 | 1370 | 750 | 1.5 | 5.5 | 1650 | ||

| ZCES390S | 900 | 1050 | 1570 | 900 | 2.2 | 5.5 | 1850 | ||

| ZCES312S | 1200 | 1350 | 1820 | 1200 | 2.2 | 5.5 | 2000 | ||

| ZCES315S | 1500 | 1650 | 2070 | Max. 2000 (Inverter Variable) | 1500 | 2.2 | 7.5 | 2500 | |

| ZCES318S | 1800 | 1950 | 2370 | 1800 | 3.7 | 7.5 | 2700 | ||

| ZCES320S | 2000 | 2150 | 2570 | 2000 | 3.7 | 7.5 | 2850 | ||

| High-performance models | ZCES345S | 450 | 570 | 970 | Max. 3000 (Inverter Variable) | 450 | 1.5 | 5.5 | 1450 |

| ZCES360S | 600 | 750 | 1170 | 600 | 1.5 | 5.5 | 1600 | ||

| ZCES375S | 750 | 900 | 1370 | 750 | 1.5 | 7.5 | 1800 | ||

| ZCES390S | 900 | 1050 | 1570 | 900 | 2.2 | 7.5 | 2000 | ||

| ZCES312S | 1200 | 1350 | 1820 | 1200 | 2.2 | 7.5 | 2200 | ||

4. Strong adaptability

The eddy current separator has a wide range of adaptability and can handle various types of waste. Whether it is industrial solid waste such as electronic waste, waste plastic doors and windows, or waste cars, the eddy current separator can effectively separate the non-ferrous metals. This adaptability makes the eddy current separator have a wide range of application value in many industries.

PS: The eddy current separator plays an important role in non-ferrous metal recycling, improving resource utilization efficiency, environmental protection and economic benefits, and adaptability. With the continuous advancement of science and technology and increasingly stringent environmental protection requirements, the development prospects of eddy current separators will be broader in the future.

Save Time! Get A Detailed Quotation Quickly.