Overview: Eddy current separator plays a vital role in garbage sorting, especially in the solid waste recycling industry. The following is a detailed description of the role of eddy current separator in garbage sorting.

A. Basic Principle of Eddy Current Separator

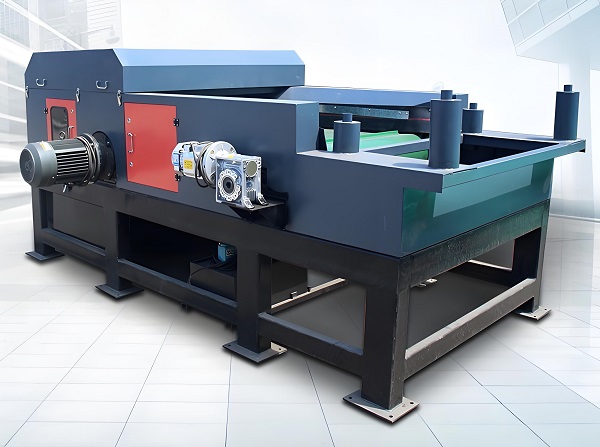

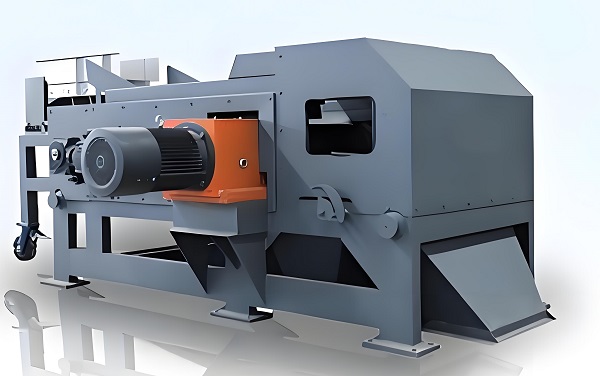

Eddy current separator

1. Principle: The working principle of eddy current separator is based on Faraday's law of electromagnetic induction and Lenz's law. When materials containing non-magnetic conductive metals (such as lead, copper, zinc and other materials) pass through an alternating magnetic field at a certain speed, induced eddy currents will be generated in these non-magnetic conductive metals. Because the material flow and the magnetic field have a relative motion speed, there is a thrust on the metal sheets and blocks that generate eddy currents. This thrust is the Lorentz force, which separates the metal from the mixed material flow.

2. Structure: The core component of the eddy current separator is a high-speed rotating magnetic drum, surrounded by an alternating magnetic field generating device. When the material passes under the magnetic drum, eddy currents will be generated inside the non-ferrous metal, and the eddy currents will generate a magnetic field in the opposite direction of the original magnetic field, thereby generating a repulsive force on the metal particles, ejecting them from the material flow, and achieving separation from other non-conductive or weakly conductive materials.

B. Types and structures of eddy current separators

Eddy current separator

Depending on the design and application requirements, eddy current separators can be divided into many types, such as linear motor eddy current separators, inclined plate eddy current separators, concentric eddy current separators, and eccentric eddy current separators.

1. Linear motor eddy current separator: The linear force generated by the linear motor under the action of electromagnetic and current is used to make the non-ferrous metal sheets in the material move in the direction of the electromagnetic field force, thereby achieving separation.

2. Inclined plate eddy current separator: Permanent magnets of N and S levels are buried alternately at a certain angle on the inclined plate. During the sliding process, the non-ferrous metals in the material change their direction of movement due to the magnetic force generated by the eddy current, and are separated.

3. Concentric eddy current separator: The internal magnetic core roller and the external magnetic roller share the same central axis, which is conducive to the stable operation of the equipment and the uniform sorting of materials.

4. Eccentric eddy current separator: The internal magnetic core roller and the external magnetic roller each have different central axes, which can increase the sorting area and improve the sorting efficiency.

5. The main components of the eddy current separator include annular conveyor belt, internal magnetic core roller, external magnetic roller, etc. The annular conveyor belt is responsible for transporting the material to the sorting area, the internal magnetic core roller generates the required high-frequency alternating magnetic field, and the external magnetic roller is used to further process the sorted material.

C. Application of eddy current separator in garbage sorting

Eddy current separator

The application scenarios of eddy current separator in the garbage treatment industry are very wide, covering many fields such as urban domestic waste, industrial waste, electronic waste, dismantling and recycling of used cars, glass recycling industry, etc.

1. Sorting of urban domestic waste: eddy current separator can separate non-ferrous metals such as aluminum cans, bottle caps and copper and aluminum alloy parts from urban domestic waste. This not only improves the resource recycling rate and reduces the amount of landfill, but also reduces the pollution to the environment during the waste treatment process and improves the environmental protection level of waste treatment.

2. Industrial waste treatment: In the field of industrial waste treatment, eddy current separators also play an important role. It can effectively recover non-ferrous metals such as copper, aluminum and other non-ferrous metals from industrial waste to achieve resource recycling. This is of great significance for improving the efficiency of industrial resource utilization and reducing production costs.

3. Electronic waste treatment: With the popularization and accelerated replacement of electronic products, the treatment of electronic waste (ie "electronic waste") has become an urgent problem to be solved. Eddy current separators can separate non-ferrous metals from electronic waste such as old household appliances (such as refrigerators, air conditioners, televisions, computers, etc.), circuit boards, etc., to achieve resource recycling and reuse. This not only helps to reduce environmental pollution, but also provides support for the sustainable development of the electronics industry.

4. Dismantling and recycling of scrapped cars: In the process of dismantling and recycling of scrapped cars, eddy current separators can recover non-ferrous metals such as aluminum or copper blocks from scrap car slices. This is of great significance for improving the resource utilization rate of scrapped cars and reducing the mining pressure on primary mineral resources.

5. Glass recycling industry: In the glass recycling industry, eddy current separators can separate non-ferrous metals such as aluminum bottle caps and small copper and aluminum particles from broken glass materials. This helps to improve the purity and value of glass recycling and provide support for the green development of the glass industry.

6. Other application areas: In addition to the above application scenarios, eddy current separators can also be used in scrap steel crushing plants, waste paper recycling industries and other fields. In scrap steel crushing plants, it can separate non-ferrous metals from scrap steel crushing tailings; in waste paper recycling industries, it can separate non-ferrous metals from papermaking residues. These application scenarios fully demonstrate the breadth and practicality of eddy current separators in the garbage disposal industry.

D. Advantages and challenges of eddy current separators

Eddy current separator

a. Advantages of eddy current separators

1. High efficiency and high precision: eddy current separators can accurately separate a variety of non-ferrous metals and improve recycling purity.

2. Strong adaptability: It is suitable for materials with a variety of particle size ranges (usually greater than 2mm) and has a wide range of processing.

3. Energy saving and low consumption: Compared with traditional methods, eddy current separators have lower energy consumption. Some models use high-strength permanent magnetic materials with stable and lasting magnetic properties.

4. Automated operation: Easy operation, one-button start, reducing manual dependence and improving work efficiency.

5. Environmentally friendly: It helps to recycle resources and reduce the pollution of waste to the environment.

6. Stable structure: The mechanical structure is reasonably designed, easy to maintain and prolong the service life of the equipment.

7. Adjustability: Sorting parameters such as magnetic field strength and material conveying speed can be adjusted as needed to meet different sorting needs.

b. Challenges of eddy current separators

1. Material characteristics: Factors such as material size, shape, and conductivity will affect the sorting effect. Therefore, before entering the sorting, it is necessary to go through a screening process to ensure that the material size is within a certain range.

2. Feeding uniformity: Feeding should be uniform, and unevenness will affect the sorting effect. It needs to be equipped with a suitable vibrating feeder to make the material pass through the sorting machine evenly.

3. Equipment selection and debugging: When selecting an eddy current sorting machine, it is necessary to comprehensively consider factors such as the equipment's processing capacity, sorting efficiency, and maintenance cost. At the same time, the debugging and parameter setting of the equipment are also key factors affecting the sorting effect.

E. Future prospects of eddy current sorting machine

Eddy current separator

As an efficient and environmentally friendly non-ferrous metal sorting equipment, the eddy current sorting machine plays an increasingly important role in garbage sorting. It not only improves the resource recycling rate and reduces environmental pollution, but also provides strong support for the sustainable development of related industries. In the future, with the continuous advancement of technology and the continuous expansion of applications, eddy current sorting machines are expected to be applied and promoted in more fields.

PS: Eddy current sorting machines have broad application prospects and huge development potential in garbage sorting. We should make full use of this technical advantage to promote the in-depth development of garbage sorting and resource recycling, and make greater contributions to achieving sustainable development goals.

Save Time! Get A Detailed Quotation Quickly.