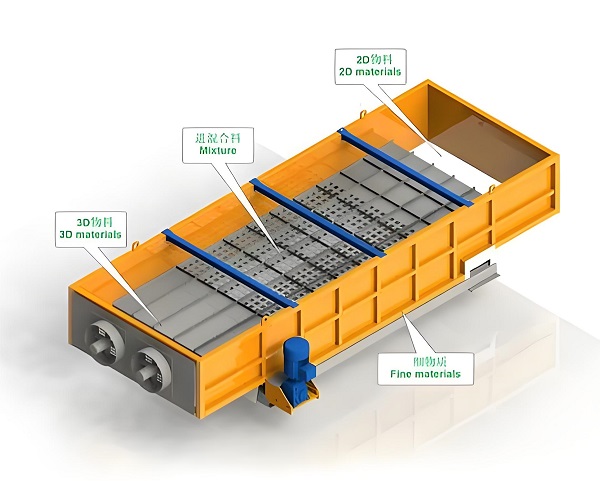

The ballistic screen is a kind of efficient screening equipment. The eccentric shaft and other driving mechanisms cause the screen plate to vibrate up and down and back and forth, causing the materials to bounce on the screen, thereby achieving fine screening. Ballistic Screen is widely used in material sorting in construction and decoration waste, domestic waste and other industries. It has the advantages of high screening accuracy, good separation effect, low noise and significant energy saving effect.

【Device Type】:Sorting equipment

【Handling Materials】:1.3D materials: refers to heavy, rolling materials such as plastic bottles, stones, wood, boxes, cans, etc. 2.2D materials: refers to light, flaky materials such as plastic films, packaging bags, paper, cartons, fiber products, etc. 3. Screening materials: refers to fine materials such as sand, gravel, organic matter, etc..

【Equipment capacity】:10-300T/H

【Equipment power】:5-150W/H

【Scope of application】:The ballistic screen of the spring screen are wide, such as construction and decoration waste resource processing center, sorting center after household waste classification, etc.

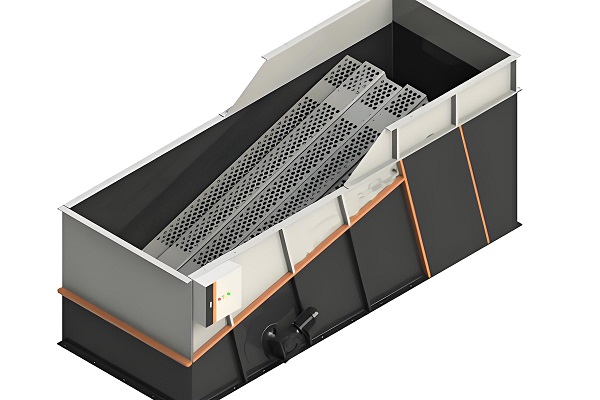

The ballistic screen(Ballistic Separator) is an efficient screening equipment. Through the driving mechanism such as the eccentric shaft, the screen plate vibrates up and down and forward and backward, so that the material bounces on the screen, thereby achieving fine screening. It is widely used in the material sorting of industries such as construction and decoration waste and domestic waste, and has the advantages of high screening accuracy, good separation effect, low noise, and significant energy saving effect.

The ballistic screen can be sorted according to the size, density and shape of the material, and separate different types of materials such as 3D materials, 2D materials and undersize. It has a simple structure, convenient operation, easy maintenance and cleaning, and can adjust the screen plate angle, speed and screen size according to the screening requirements of different materials.

Ballistic Screen

The ballistic screen has a wide range of application scenarios, such as construction and decoration waste resource processing centers, sorting centers after domestic waste classification, etc., which can significantly improve the efficiency and environmental protection level of waste treatment. At the same time the ballistic screen also has the characteristics of high safety and strong adaptability, providing important technical support for the urban waste treatment system.

The ballistic screen is an advanced screening equipment, which is widely used in the field of solid particle screening and liquid-solid separation, especially in the treatment of mixed garbage, construction waste, domestic garbage and other industries.

Ballistic Screen

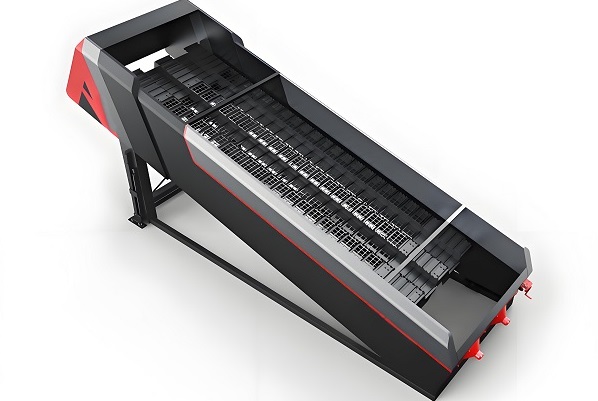

The ballistic screen is a device that uses the principle of unbalanced vibration to achieve material separation. It mainly uses the rapid vibration of the screen to make the material jump forward on the screen surface, thereby achieving the classification and screening of materials of different particle sizes. Specifically, the vibrator generates periodic vibration force to make the screen box vibrate in the vertical and horizontal directions. After the material enters the screen box through the feed port, it is affected by the vibration force and presents a flow state in the screen box. Larger particle materials are blocked by the screen and cannot pass through the screen aperture, while smaller particle materials can pass through the screen aperture to achieve screening.

The ballistic screen is mainly composed of a feed port, a screen body, a screen, a discharge port, a vibration motor and other parts. Among them, the screen body is the main structure of the spring screen, which is used to hold materials and perform screening operations; the screen is the key component to achieve material separation, and its aperture size determines the particle size of the screened material; the vibration motor provides power to make the screen body vibrate, thereby achieving material screening.

As an efficient screening equipment, the working principle of the ballistic screen is mainly based on the combination of vibration and bouncing motion, and the material classification and screening are achieved through a specific mechanical structure. The following is a detailed explanation of the working principle of the ballistic screen:

1.Vibration generation: The vibration of the ballistic screen is mainly driven by the vibrator. The vibrator is equipped with an eccentric block or an eccentric shaft. When the motor is started, the eccentric block or the eccentric shaft generates a rotational motion under the drive of the motor, thereby generating centrifugal force. This centrifugal force is transmitted to the screen body through the structure of the vibrator, causing the screen body to vibrate in the vertical and horizontal directions.

Working principle of the ballistic screen

2. Screen body vibration: Under the action of the vibrator, the screen body begins to vibrate periodically. This vibration not only makes the screen body jump up and down in the vertical direction, but also produces a certain displacement in the horizontal direction. This composite vibration mode causes the material on the screen to be subjected to continuous impact and friction, thereby achieving a screening effect.

3. Material bouncing: When the material enters the screen body, it is affected by the vibration of the screen body and begins to bounce forward on the screen. Larger granular materials are easily blocked by the screen due to their large mass and relatively small bounce force, forming the upper layer of materials. Smaller granular materials, however, can more easily pass through the aperture of the screen due to their small mass and large bounce force, forming the lower layer of materials. In this way, the materials are layered and separated on the screen.

4. Screening process: During the screening process, the materials are constantly subjected to the vibration and bounce of the screen body, and gradually separated into particles of different sizes. Larger particles are blocked by the screen in the upper layer, while smaller particles fall into the lower layer through the aperture of the screen. At the same time, due to the vibration of the screen body, the materials are constantly rolling and moving on the screen, making the screening process more uniform and efficient.

5. Material discharge: After the screening is completed, materials of different particle sizes are discharged through the discharge port of the screen body respectively. The large particle materials in the upper layer are discharged through the discharge port on the upper part of the screen body, while the small particle materials in the lower layer are discharged through the discharge port at the bottom of the screen body. In this way, the ballistic screen realizes the grading and screening of materials.

6. Adjustment and control: The screening effect of the ballistic screen can be achieved by adjusting the amplitude, frequency of the vibrator and the aperture size of the screen. The adjustment of the amplitude and frequency can change the vibration intensity and frequency of the screen body, thereby affecting the bouncing effect and screening efficiency of the material. The adjustment of the screen aperture can directly affect the particle size of the screened material.

PS: The working principle of the ballistic screen is mainly based on the combination of vibration and bouncing motion. The vibrator generates vibration, which makes the screen body produce composite vibration in the vertical and horizontal directions, so that the material bounces forward and separates on the screen. By adjusting the amplitude, frequency of the vibrator and the aperture size of the screen, efficient screening and grading of materials can be achieved.

As an efficient screening equipment, the ballistic screen has a wide range of uses, covering multiple industries and fields. The following is a detailed introduction to the main uses of the ballistic screen:

A. Solid particle screening

Ballistic Screen

1. Mining field: In the mining field, the ballistic screen is often used for ore screening and grading. Through screening, the ore can be classified according to different particle sizes to provide suitable raw materials for subsequent crushing, grinding and other processes.

2. Construction and decoration waste treatment: In the construction and decoration waste treatment, the ballistic screen can separate different types of building materials, such as stone, wood, metal, etc., to facilitate subsequent recycling.

3. Agricultural field: In the agricultural field, the ballistic screen can be used for the screening of agricultural products such as grains and seeds, removing impurities and unqualified products, and improving the quality and purity of agricultural products.

B. Liquid-solid separation

Ballistic Screen

1. Sewage treatment: In the sewage treatment process, the ballistic screen can be used to remove solid impurities such as suspended matter and floating matter in the sewage, and improve the sewage treatment efficiency and effluent water quality.

2. Chemical industry: In chemical production, the ballistic screen is often used to separate solid particles from liquids, such as the recovery and reuse of catalysts and fillers.

C. Waste treatment and resource recovery

1. Urban domestic waste treatment: The ballistic screen can be used for the pretreatment of urban domestic waste, separating recyclable materials (such as plastic bottles, metal cans, etc.), and improving the resource utilization rate of waste.

2. Industrial waste treatment: In industrial waste treatment, the ballistic screen can separate valuable materials, such as scrap metals, plastics, etc., reduce the amount of waste landfill, and reduce environmental pollution.

D. Other uses

1. Food industry: In the food industry, the ballistic screen can be used for food screening and grading, such as candy, chocolate and other small foods screening and packaging.

2. Pharmaceutical industry: In the pharmaceutical industry, the ballistic screen can be used for the screening and purification of pharmaceutical raw materials to ensure the quality and safety of drugs.

PS. The ballistic screen has a wide range of uses. It is not only suitable for the screening and grading of solid particles, but also can be used in many fields such as liquid-solid separation, waste treatment and resource recovery. With the continuous advancement of technology and the continuous expansion of the market, the application scope of the spring screen will be further expanded, providing strong support for the development of various industries.

As an advanced screening equipment, the ballistic screen has shown remarkable characteristics and advantages in many fields with its unique working principle and structural design. The following is a detailed summary of the characteristics and advantages of the ballistic screen:

A. Characteristics of the ballistic screen

Ballistic Screen

1. Efficient screening:

a. The ballistic screen uses vibration and bouncing motion to quickly separate the material on the screen, with high screening efficiency.

b. The multi-layer screen design can achieve multi-level screening to meet the screening needs of materials of different particle sizes.

2. Not easy to block:

a. The material jumps forward on the screen, reducing the adhesion and blockage of the material to the screen.

b. The screen is made of high-strength and high-wear-resistant materials, which is not easy to deform and break, further reducing the risk of blockage.

3. Strong adaptability:

a. The ballistic screen can screen according to the characteristics of the material (such as particle size, density, shape, etc.).

b. The equipment has a simple structure, is easy to adjust and maintain, and can be modified and upgraded according to actual needs.

4. Intelligent control:

a. Equipped with an intelligent control system, the operating status of the equipment can be monitored in real time.

b. Automatically adjust the vibration frequency and amplitude according to the material conditions to improve the screening effect.

5. Environmental protection and energy saving:

a. The fully enclosed structure design effectively prevents dust from spilling out and meets environmental protection requirements.

b. The equipment has low noise and will not affect the surrounding environment.

c. Low energy consumption helps to reduce production costs.

B. Advantages of the ballistic screen

Ballistic Screen

1. Improve production efficiency:

a. The ballistic screen can quickly process a large amount of material and improve production efficiency.

b. The multi-stage screening design can achieve one-time feeding and multiple screening, saving time and labor costs.

2. Optimize product quality:

a. High screening accuracy can ensure the consistency of product quality.

b. It can remove impurities and unqualified products in the material and improve the purity and quality of the product.

3. Reduce operating costs:

a. The equipment has a simple structure, is easy to maintain and maintain, and reduces maintenance costs.

b. Low energy consumption helps to reduce production costs.

c. The screen has a long service life, reducing the frequency and cost of replacing the screen.

4. Promote resource recycling:

a. In the field of garbage disposal and resource recycling, the pop-up screen can separate valuable materials.

b. It helps to reduce the amount of landfill waste and reduce environmental pollution.

5. Improve safety:

a. The high degree of automation reduces the risk of direct contact between operators and materials.

b. The equipment operates stably and reliably, reducing the probability of safety accidents.

PS: The bouncing screen has been widely used in many fields for its characteristics and advantages such as efficient screening, not easy to block, strong adaptability, intelligent control, environmental protection and energy saving. With the continuous advancement of technology and the continuous expansion of the market, the application scope of the bouncing screen will be further expanded, providing strong support for the development of various industries.

When choosing a suitable ballistic screen, you need to consider several factors to ensure that the equipment can meet production needs and has good performance. Here are some key purchase guidelines:

A. Clear screening needs

Ballistic Screen

1. Material characteristics: Understand the properties of the material to be screened, such as particle size, density, humidity, viscosity, etc., to determine the required screening accuracy and screen aperture.

2. Processing capacity: Determine the processing capacity of the ballistic screen according to the production scale, that is, the amount of material that needs to be processed per hour.

3. Screening efficiency: Choose products with high screening efficiency to ensure the classification and screening effect of garbage. Generally speaking, a better garbage ballistic screen can achieve a screening efficiency of more than 90%.

B. Consider equipment performance

Ballistic Screen

1. Stability: The stability of the equipment is crucial for long-term operation and screening effect. Choosing a ballistic screen with good stability can reduce failure rate and downtime.

2. Durability: The durability of the ballistic screen depends on its material and manufacturing process. Choosing wear-resistant and corrosion-resistant materials, as well as equipment that has been finely processed and strictly inspected, can extend the service life and reduce maintenance costs.

3. Noise and energy consumption: Choosing a ballistic screen with low noise and low energy consumption can help improve the working environment and reduce production costs.

C. Evaluate the ease of use of the equipment

1. Ease of operation: Choosing a ballistic screen that is easy to operate and easy to control can reduce the difficulty of operation and labor costs.

2. Ease of maintenance: The ease of maintenance of the equipment is also one of the factors that need to be considered. Choosing equipment that is easy to disassemble, clean and repair can reduce downtime and maintenance costs.

D. Consider after-sales service

1. Supplier reputation: Choosing a supplier with good reputation and reputation can ensure the quality and after-sales service of the equipment.

2. Technical support: Find out whether the supplier provides technical support and training services so that problems can be solved in time when the equipment is used.

3. After-sales service network: Choosing a supplier with a complete after-sales service network can ensure that the equipment can be repaired and replaced in time when a failure occurs.

E. Reference price and cost-effectiveness

1. Price comparison: During the purchase process, you can compare the prices of ballistic screens of different brands and models to choose products with high cost-effectiveness.

2. Cost-benefit analysis: In addition to considering the price of the equipment, it is also necessary to consider factors such as the equipment's operating cost, maintenance cost, and service life, and conduct a comprehensive cost-benefit analysis.

PS: When purchasing a suitable ballistic screen, you need to consider multiple factors such as screening requirements, equipment performance, ease of use, after-sales service, and price and cost-effectiveness. By comprehensively evaluating these factors, you can choose the ballistic screen equipment that best suits your production needs.

| Model (model) | Number of springboards (pcs) | Sieve plate width (mm) | Sieve plate length (mm) | Sieve plate area (m³) | Processing capacity (t/h) | Sieve hole size (mm) | Drive power (kw) |

| ZCBS1745-4P | 4 | 400 | 4500 | 400X1700 | 10-30 | 5-50 | 22 |

| ZCBS2145-5P | 5 | 400 | 4500 | 400X1700 | 15-30 | 5-50 | 22 |

| ZCBS2155-5P | 5 | 400 | 5500 | 400X2100 | 15-40 | 5-50 | 22 |

| ZCBS2555-6P | 6 | 400 | 5500 | 400X2490 | 20-50 | 5-50 | 30 |

2025-01-03

2025-01-03

2025-01-03

2025-01-03

2024-11-14

2024-11-14

2024-11-14

2024-11-14

2024-11-14

2024-11-14Save Time! Get A Detailed Quotation Quickly.