Preface: The ballistic screen is a screening equipment commonly used in industrial production, and is widely used in mining, building materials, chemicals and other fields. Due to its efficient screening ability and good adaptability, the ballistic screen plays an important role in modern production. However, in order to ensure its long-term stable operation, regular repairs and daily maintenance are particularly important. This article will explore in depth how to effectively repair and maintain the ballistic screen to help users extend the service life of the equipment and improve production efficiency.

A. Daily maintenance of the ballistic screen:

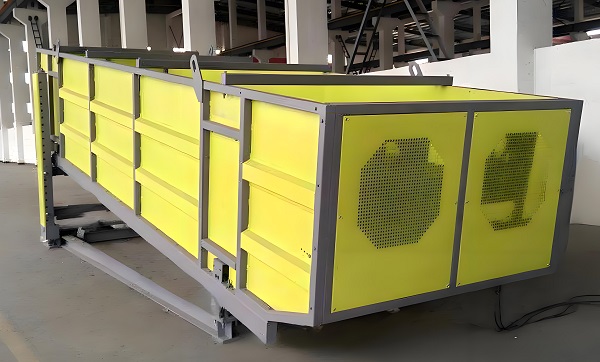

Ballistic Screen

a. The importance of daily maintenance: Daily maintenance can not only ensure the normal operation of the ballistic screen, but also effectively prevent equipment failures and reduce maintenance costs. Maintenance work includes but is not limited to regular inspections, cleaning, lubrication and adjustments. By promptly discovering and solving potential problems, companies can avoid large-scale production stoppage losses and effectively extend the service life of the equipment.

b. Regular inspections

Regular inspections are very necessary for the ballistic screen. In daily operations, operators should regularly inspect the following components:

1. Screen: Regularly check the wear of the screen and replace damaged or blocked screens in time to ensure screening efficiency.

2. Motor: Ensure that the motor connection is stable, check whether the cable is worn, and avoid motor failure.

3. Vibration part: Regularly check the connection parts of the vibration system to ensure that there is no looseness.

4. Base and bracket: The support of the base should be firm to avoid loosening of the bracket due to vibration.

c. Bounce screen cleaning

During the operation of the bounce screen, the residue of the material will accumulate over time and affect the working efficiency of the equipment. Therefore, regular cleaning is particularly important. The cleaning work can be divided into the following steps:

1. Screen cleaning: Use a high-pressure water gun to clean the screen to prevent the screen from being blocked due to material accumulation.

2. External cleaning of the equipment: Clean the outside of the equipment to keep the equipment clean and tidy, which is conducive to the operation of employees.

3. Lubrication system cleaning: Clean the lubrication system regularly to ensure the cleanliness of the lubricating oil to reduce wear.

d. Lubrication and replacement

Good lubrication is an important guarantee for the normal operation of the equipment. Different parts require different types of lubricants. Therefore, in daily maintenance, the following points should be noted:

1. Selection of lubricating oil: Select the appropriate lubricating oil according to the equipment manual to ensure that its viscosity and type meet the standards.

2. Lubrication cycle: Lubricate regularly according to the use of the equipment. It is generally recommended to check the lubrication status every week.

3. Replacement cycle: Regularly replace lubricating oil and grease to avoid equipment wear caused by poor lubrication.

B. Maintenance guide for ballistic screen

Ballistic Screen

Even if daily maintenance is paid attention to, the ballistic screen may still fail during use. At this time, understanding some basic maintenance knowledge can help operators solve the problem quickly.

a. Troubleshooting

When the ballistic screen fails, the first thing to do is to troubleshoot:

1. Abnormal vibration: Check whether the vibration motor is working properly. If the motor is abnormal, replace the faulty motor in time.

2. Material leakage: Check whether the screen is damaged or blocked, and replace it if necessary.

3. Excessive noise: Check the tightness of each component to ensure that there is no looseness, and check whether the motor and vibration part are normal.

b. Repair of common faults

1. Screen wear: If the screen is found to be seriously worn, a new screen should be replaced in time. When replacing, ensure that the new screen is consistent with the original screen specifications and is firmly fixed.

2. Motor failure: Motor failure is one of the main reasons for equipment shutdown. If the motor burns out, a new motor consistent with the original model needs to be replaced. At the same time, check whether the motor connection line is intact to avoid similar problems again.

3. Vibration system problems: If the spring of the vibration system is found to be invalid, it should be replaced in time, and ensure that the components of the vibration system are connected tightly.

Ballistic Screen

c. Maintenance records and data analysis

In order to better maintain the ballistic screen, it is recommended to establish a maintenance record and data analysis system. Recording the content of each maintenance, including the components inspected, the problems found and the handling situation, can provide important reference for future maintenance. At the same time, regular analysis of the equipment's operating data can help identify potential problems and solve them, and further improve the overall performance of the equipment.

PS: Through regular inspection, cleaning, lubrication and timely maintenance, enterprises can not only extend the service life of the ballistic screen, but also ensure the efficient operation of the equipment during the production process, thereby improving overall production efficiency. A good daily maintenance system and standardized maintenance process will bring more stable protection to the production operation of the enterprise. It is hoped that the experience and suggestions provided in this article can help operators and managers in related industries and provide guidance and support for their work.

Save Time! Get A Detailed Quotation Quickly.