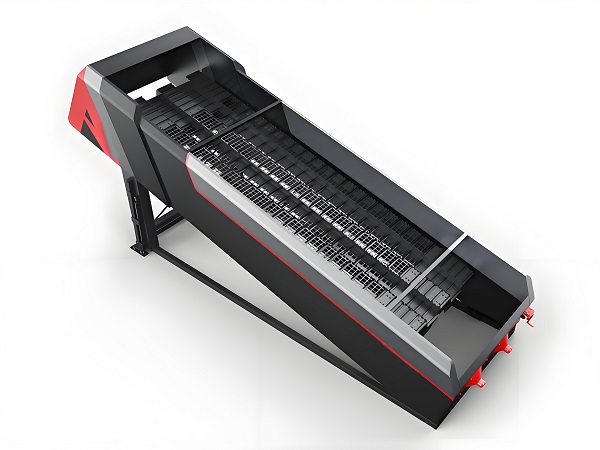

Ballistic Separator is an efficient screening equipment widely used for material sorting in industries such as decoration waste, household waste, and construction waste. It drives the sieve plate to move up, down, forward, and backward through an eccentric shaft or vibration motor, causing the screened material on the sieve plate to shake and disperse into different material parts, facilitating subsequent processing. The Ballistic Separator can separate 3D materials (such as plastic bottles, stone, etc.), 2D materials (such as plastic film, paper, etc.), and undersized materials (such as sand and residue, etc.), and the angle and speed of the screen plate can be adjusted. The screen plate and mesh size can also be customized. This device is sturdy, durable, suitable for continuous operation, easy to maintain, and cost-effective, making it an important tool in the field of solid waste treatment and resource recycling.

A. Ballistic Separator Introduction:

Ballistic Separator, also known as Ballistic Separatoring machine, is used to classify garbage according to its different characteristics. It can separate plastic waste from cardboard, waste paper, and film. It is also suitable for separating light substances such as films from cylindrical garbage bottles and cans. Depending on the speed of movement, 3D shaped garbage will be bounced off the screen, while 2D shaped garbage such as film and paper will be bounced onto the screen, achieving the goal of garbage classification.

Bounce sorting screen is a device that sorts materials based on their shape and specific gravity. It is an ideal sorting screen for processing and sorting household waste, pressed kitchen waste, paper recycling and other industries. The bouncing sorting screen drives the sieve plate to move up, down, and forward and backward through an eccentric shaft, causing the screened materials on the sieve plate to shake and disperse into heavy, rolling 3D material parts (such as plastic bottles, wood, cans, etc.), light, flat 2D material parts (film, paper, cardboard), and undersized material parts (sand, food residues), facilitating subsequent processing.

Garbage bouncing sorting machine is a shutdown device with separation function designed for sorting inorganic particles in garbage after rough crushing. This machine utilizes the characteristics of crushed waste materials to perform sorting operations based on the different densities of the materials when the waste reaches a certain particle size. The garbage bouncing sorting machine is designed with a bouncing function, which separates inorganic particles or other hard particles while conveying materials. The separated particles move in the opposite direction to the conveyed material to achieve the purpose of sorting.

The rotating sieve plate of the bouncing sorting machine will sort the garbage onto or off the screen according to its different appearance, shape, and characteristics. The bouncing sorting machine classifies garbage according to its different characteristics, and can separate plastic garbage from cardboard, waste paper, and film. It is also suitable for separating light substances such as films from cylindrical garbage bottles and cans. Depending on the speed of movement, 3D shaped garbage will be bounced off the screen, while 2D shaped garbage such as film and paper will be bounced onto the screen, achieving the goal of garbage classification.

The rotating sieve plate of the bouncing sorting machine will sort the garbage onto or off the screen according to its different appearance, shape, and characteristics. The bouncing sorting machine classifies garbage according to its different characteristics, and can separate plastic garbage from cardboard, waste paper, and film. It is also suitable for separating light substances such as films from cylindrical garbage bottles and cans. Depending on the speed of movement, 3D shaped garbage will be bounced off the screen, while 2D shaped garbage such as film and paper will be bounced onto the screen, achieving the goal of garbage classification. By adjusting the angle of the sieve plate, the sorting accuracy can be adjusted. Bouncing sorting machines are usually installed at the starting machine of the automatic sorting line in garbage recycling systems to improve the separation efficiency of the back-end separator.

B. The product advantages and features of Zhongcheng Ballistic Separator:

Outstanding advantages: The main features of the Ballistic Separatoring machine include: the screen is made of stainless steel material, with advanced structure, sturdy and durable, using large clearance bearings, thin oil lubrication, low noise, long service life, strong universality of components, and easy maintenance; The installation angle of the bouncing sorting machine can be adjusted according to the material situation, and the speed of the bouncing sorting machine can be variable frequency controlled according to different materials.

1. The sieve plate has a large size and high processing capacity

2. The crankshaft is stable and durable

3. Fully enclosed and dust-proof

4. The sieve plate is detachable and easy to replace

5. The angle of the sieve plate can be flexibly adjusted

C. Applicable materials for Ballistic Separator:

1. Sort combustible waste, recyclable waste, and backfill waste

2. Sort glass bottles and ceramics.

3. Separate plastic packaging from film or waste paper through sorting

4. Can screen out inert impurities of 10mm.

D. Ballistic Separator output material:

1. Flat and lighter 2D materials: film, paper, cardboard, textiles, and fiber materials

2. Debris: The material will be separated based on the particle size and diameter of the paddle shaped holes

3. Rolling and heavier 3D materials: plastic containers, bottles, stones, wood, cans, and metal materials

E. The working principle of Ballistic Separator:

Ballistic Separatoring machine is a device that sorts materials based on the size, density, and shape of different components. It is the most ideal equipment for processing and sorting household waste, old waste, construction waste, decoration waste, and so on. The Ballistic Separator sorting machine drives the screen plate to move up and down through an eccentric shaft, making it easier to process the 3D material parts (such as plastic bottles, wood, bricks, etc.) and lightweight flat 2D material parts (film, paper, and cardboard) on the screen plate, as well as the fine material parts (sand and food residue) under the screen plate.

In summary, the Ballistic Separator is an efficient screening device that uses a specific driving mechanism to cause the screen plate to vibrate up, down, back, and forth, thereby achieving material screening. This device is widely used in the treatment of various solid wastes such as decoration waste, household waste, and construction waste, and can effectively separate materials of different sizes and densities. Ballistic Separators have the advantages of simple structure, convenient operation, and high screening efficiency. The screen angle and vibration speed can be adjusted to meet the screening needs of different materials. At the same time, the sieve plate and mesh size can also be customized according to customer needs to meet diverse screening requirements. In addition, the Ballistic Separator also has the characteristics of being sturdy, durable, and easy to maintain. The sieve plate is made of wear-resistant materials, which can withstand significant material impact and wear, extending the service life of the equipment. Meanwhile, the maintenance of the equipment is relatively simple, reducing operating costs. Ballistic Separator is an efficient and practical screening equipment that provides strong support for solid waste treatment and resource recycling.

Save Time! Get A Detailed Quotation Quickly.