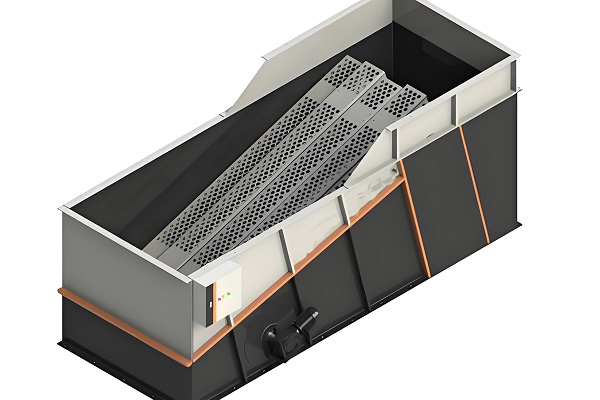

Preface:As a leader in the field of modern screening, the Ballistic Separator has demonstrated strong vitality and market potential with its unique vibration screening principle and wide application areas. Ballistic Separators have shown high application value in various material processing and grading operations due to their high efficiency, energy saving, and easy maintenance. Due to its unique design and efficient performance, it plays an important role in multiple industries, especially in the fields of solid waste treatment and resource recycling.

Ballistic Separator

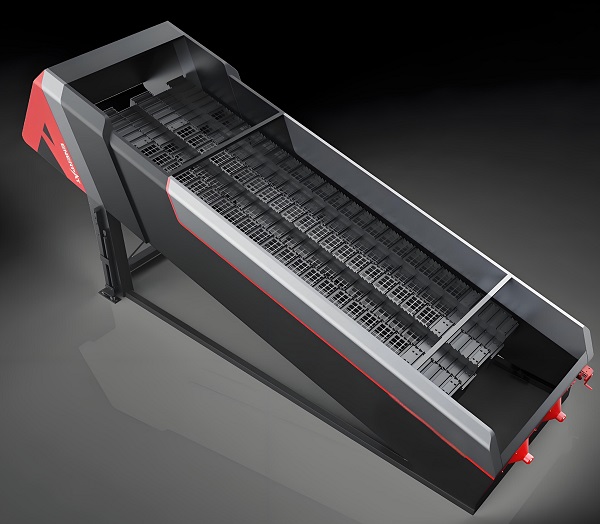

Ballistic Separator, also known as ballistic screen, 3D screen, bouncing sorting machine, etc., is a device that sorts materials based on their shape, size, and specific gravity. Ballistic Separator drives the sieve plate to move up and down, back and forth through an eccentric shaft, causing the screened materials on the sieve plate to shake and disperse into heavy/rolling material parts, light/flat material parts, and undersized materials. The parts are divided into three outlets for the next detailed sorting step. By using different sieve sizes, the machine can also effectively classify fine particles. Adjustable tilt angle, high sorting efficiency. The durable crankshaft and replaceable blade components ensure low operating costs and easy maintenance. It is an ideal equipment for processing and sorting construction waste, decoration waste, aged waste, paper recycling and other industries.

Zhongcheng Machinery's uniquely designed Ballistic Separator can withstand long-term operation of construction and decoration waste with a size of less than 250mm, which is different from the commonly seen lightweight European style Ballistic Separator in the market. What is the quality of a Ballistic Separator? It's not about whether it can bounce, but whether it can run stably for a long time!! Zhongcheng Mechanical Ballistic Separator welcomes various comparisons, tests, and rigorous testing, both domestic and foreign.

Ballistic Separator

A. The working principle of Ballistic Separator

The crankshaft is driven by a reduction motor, which drives the main shaft and eccentric shaft to rotate. The eccentric shaft connects the sieve plate and rotates in a hula hoop style around the crankshaft. The material is bounced up on the sieve plate, and the material is sorted out by utilizing the difference in friction (climbing force) between the sieve plate and the material.

The heavy-duty Ballistic Separator originates from the ballistic screen abroad and is a device that sorts materials based on the size, density, and shape of different components. It is a coarse screening equipment for processing and sorting construction and decoration waste, pressed kitchen waste, paper recycling and other industries. The Ballistic Separator drives the sieve plate to move up and down forward and backward through an eccentric shaft (crankshaft gear, etc.), causing the solid waste on the sieve plate to be shaken and scattered into heavy, rolling 3D material parts (such as plastic bottles, wood, cans, etc.) and light, flat 2D material parts (film, paper, cardboard) and undersized material parts (sand, food residue), facilitating subsequent processing.

Under the action of the driving motor, the bouncing sorting screen is connected to the support seat and screen plate through a parallel four-bar mechanism consisting of an active shaft, a passive shaft, and an eccentric wheel (crankshaft, chain, etc.) to form a parallel four-bar mechanism. The screen plate produces a reciprocating circular motion similar to bouncing, separating the material input from the feeding port into three types: 3D materials with large particle size and good rebound effect, 3D materials with small particle size and poor rebound effect, 2D materials with large particle size and poor rebound effect, flat and lightweight, which are respectively received by three discharge hoppers.

Ballistic Separator

B. A Ballistic Separator of the working principle

1. Function of vibration source: Whether using a vibration motor or an exciter as a vibration source, its core is to generate a controllable vibration frequency and amplitude, which is transmitted to the screen body through connecting devices such as springs and rubber shock absorbers. The vibration motor is directly installed on the screen body and generates vibration through the rotation of its internal eccentric block; And the exciter is usually used as an external device, transmitting power to the screen body through transmission devices such as pulleys and couplings.

2. Material separation process: Under the action of high-frequency vibration, the material not only undergoes linear throwing motion on the sieve surface, but also jumps and diffuses, which helps small particles penetrate the sieve holes. High frequency vibration can effectively reduce the possibility of material clogging the sieve holes, improve screening efficiency, and is particularly suitable for separating fine-grained materials. Meanwhile, the centrifugal force generated by vibration also facilitates the separation of water from the material, achieving efficient dehydration effect

C. Applicable materials for Ballistic Separator:

According to the different climbing and bouncing abilities of different materials, the screening process will be affected by the tilt angle. Therefore, the hydraulic lifting system is used to adjust the angle between the box and the sieve plate as a whole to achieve the adjustment of the bouncing lifting angle of the sorted materials.

3D materials: Refers to heavier, rolling materials such as plastic bottles, stones, wooden blocks, boxes, cans, etc;

2D materials: refers to lighter, sheet-like materials such as plastic film, packaging bags, paper, cardboard boxes, fiber products, etc

Screening material: refers to the screened material, such as sand, organic matter, materials smaller than the sieve size, finely divided materials, sand, etc.

Ballistic Separator

D. Advantages of Ballistic Separator:

Traditional garbage sorting equipment only has two types of materials, above and below the screen, while the Ballistic Separator can separate three types of materials, making material classification more refined and convenient for subsequent processing. The equipment is not only lighter in weight, flexible and convenient, with low cost and space saving, modular design, good interchangeability of components, and easy maintenance. It has the characteristics of high screening efficiency, large processing capacity, and good garbage sorting effect. The box body is welded with profiles, and the lining plate is made of imported wear-resistant steel plate. The equipment is sturdy and suitable for continuous operation; The inclination angle of the sieve plate and the box body is adjusted by the hydraulic system from 12 ° to 20 ° as a whole, making the adjustment angle convenient and the adjustment range wide; Adopting a modular eccentric crankshaft design, it has good performance and low maintenance costs. The deceleration motor adopts frequency conversion control, combined with angle adjustment of the sieve plate, which can adapt to the screening of various materials. Based on the characteristics of the above equipment and the complex nature of solid waste in China, it is mainly used in front-end pre sorting of construction and decoration waste, light materials from municipal solid waste incineration slag, and some industrial waste sorting systems

F. Detailed analysis of structural composition

1. Sieve: It is a key component that determines the screening accuracy. Different aperture and material sieves are selected based on the characteristics of the processed material.

2. Vibration source: Vibration motor or exciter, providing the driving force required for vibration.

3. Screen body: The main structure that carries the screen mesh and transmits vibration, requiring sufficient strength and stability.

4. Vibration damping device: including springs, rubber pads, etc., used to absorb vibration energy, reduce impact and noise on the foundation.

5. Legs: Support the entire equipment to ensure stable operation.

6. Electric motor: provides power for vibration motors or exciters.

G. In addition to the application scenarios you mentioned, high-frequency Ballistic Separator are also widely used in:

1. Garbage screening: It is widely used in construction and decoration waste resource treatment centers, sorting centers for household waste after classification, and waste reduction before incineration in pyrolysis and gasification furnaces

2. Mining: Classification and dehydration in mineral processing, especially for the selection of fine-grained minerals.

3. Chemical industry: particle size classification, wet screening, and drying dehydration of chemical products.

4. Food industry: screening and purification of raw materials such as grains, flour, and sugar.

5. Pharmaceutical field: Screening of raw materials and excipients to ensure product quality.

6. Agriculture: Seed grading, grain cleaning, etc., to improve seed quality and processing efficiency.

Technical parameter table of Ballistic Separator:

| model | EBS-6327 | EBS-6355 |

| Motor power | 11KW | 22KW |

| Springboard length | 6300mm | 6300mm |

| Springboard width | 340mm | 340mm |

| Number of Springboards | eight | sixteen |

| Screen hole size of springboard | 8-50mm | 8-50mm |

| Equipment external dimensions | 8500/3900/4800mm | 8500/11200/4800mm |

| Equipment weight | 14ton | 20ton |

PS:With the continuous advancement of technology and the deepening expansion of the market, Ballistic Separators will continue to innovate and meet increasingly diverse screening needs. In the future, Ballistic Separators will continue to develop towards intelligence, high efficiency, energy conservation, customization, and modular design, providing more efficient, stable, and environmentally friendly screening solutions for industrial production. At the same time, manufacturers of Ballistic Separators will actively respond to national environmental policies and promote the green upgrading and sustainable development of equipment. We believe that with the joint efforts of all colleagues, the Ballistic Separator will occupy a more important position in future market competition and contribute more to the development of the industrial screening field. Let's join hands and create a better future for Ballistic Separators!

Save Time! Get A Detailed Quotation Quickly.