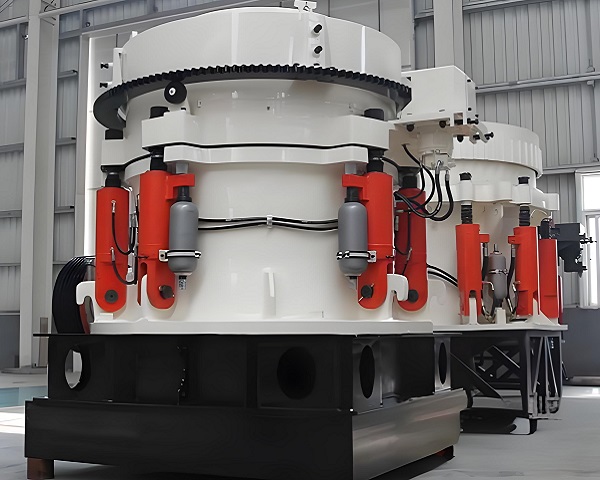

Cone crushers, as core equipment in fine crushing operations in industries such as mining and infrastructure, directly determine the production line's capacity, energy consumption, and overall efficiency. Currently, some enterprises suffer from insufficient equipment throughput, rapid wear and tear of vulnerable parts, and frequent malfunctions due to improper selection, unreasonable operating parameters, and lagging maintenance. With the upgrading of industrial production's demand for high efficiency and low carbon emissions, improving cone crusher efficiency has become an urgent industry need. This article provides a systematic solution from four core dimensions: selection and adaptation, operation optimization, maintenance, and structural modification, combined with specific machine parameters and practical cases, to help enterprises break through efficiency bottlenecks and achieve cost reduction, efficiency improvement, and stable production.

A. Precise Selection and Working Condition Adaptation: The Foundation for Efficiency Improvement

The efficiency of a cone crusher is directly related to the material characteristics and the matching degree of the equipment model. Scientific selection is key to avoiding "oversized equipment for undersized parts" or "undersized equipment for oversized parts," laying the foundation for efficient operation from the source.

1. Precise Matching of Material Characteristics and Equipment Parameters

For materials with different hardness and moisture content, cone crushers with corresponding chamber types and materials must be selected. When processing high-hardness materials with a Mohs hardness of 7 or higher (such as granite and basalt), a short-head or medium-cavity hydraulic cone crusher (such as the HPT series) should be selected. Its crushing wall and jaw walls are made of high-chromium alloy or hard alloy, offering 2-3 times better wear resistance than ordinary high-manganese steel, thus preventing efficiency loss due to rapid liner wear. For sticky materials with a moisture content exceeding 12% (such as wet clay and weathered rock), a model with an anti-clogging design should be selected, or a drying process should be added before feeding to prevent material from sticking and clogging in the crushing chamber, which could reduce throughput by more than 30%. Simultaneously, the feed particle size must be strictly controlled within 80% of the equipment's rated feed inlet. Excessively large materials are prone to getting stuck at the crushing chamber inlet, requiring manual cleaning and severely impacting continuous operation efficiency.

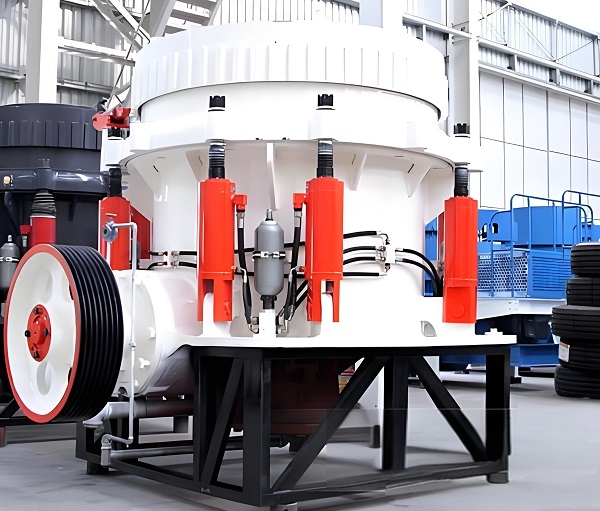

2. Reasonable Matching of Capacity Requirements and Equipment Model Select an appropriate model based on the actual processing capacity of the production line to avoid wasted capacity or overload. For example, small quarries (daily processing capacity below 500 tons) can use the PYB-900 spring cone crusher, with a motor power of 55kW and a processing capacity of 20-60t/h; large mines or infrastructure projects (daily processing capacity above 2000 tons) should use the HST-500 high-efficiency hydraulic cone crusher, with a motor power of 220kW and a processing capacity of 180-450t/h. It adopts a multi-cylinder hydraulic system, achieving a crushing ratio of 10-15, which significantly improves the efficiency of medium and fine crushing. Furthermore, the cavity type should be selected according to the required output particle size: a standard cavity is suitable for medium crushing (output particle size 15-30mm), while a short-head cavity is suitable for fine crushing (output particle size 5-15mm), avoiding repeated crushing of qualified materials due to improper cavity design, thus reducing energy consumption and efficiency.

B. Standardized Operation and Parameter Optimization: Real-time Improvement of Operating Efficiency

With proper equipment selection, standardized operation and dynamic parameter adjustments can significantly improve crushing efficiency and reduce downtime without increasing equipment investment.

1. Uniform Feeding and Stable Load Control

Using a quantitative feeder (such as a belt scale) ensures uniform and continuous feeding, guaranteeing the crushing chamber is in an optimal state of "full but not clogged." Fluctuations in feed rate cause drastic changes in motor load: excessive feeding can lead to equipment overload and shutdown, while insufficient feeding results in idling, wasting energy and reducing efficiency. Ideally, the equipment load should be maintained at 75%-90% of its rated power. By adjusting the feeding speed, a stable material layer is formed within the crushing chamber, utilizing the principle of layered crushing to improve crushing efficiency by 15-20%. Simultaneously, installing a magnetic separator and screening device at the feed inlet removes iron blocks and large, uncrushable materials in advance, preventing them from entering the crushing chamber and damaging the liner, causing equipment jamming, and extending continuous operating time.

2. Dynamic Optimization and Adjustment of Core Parameters The discharge port size and rotor speed are adjusted rationally to balance throughput and output quality. The discharge port size needs to be set according to the target output particle size. Too small a size increases crushing difficulty and reduces throughput; too large a size requires secondary processing by subsequent screening equipment, increasing the process load. Generally, the discharge port size should be 5-10mm larger than the target output particle size. For example, when producing fine materials smaller than 10mm, the discharge port can be set to 12-15mm, allowing for the separation of qualified materials through subsequent screening, balancing efficiency and accuracy. The rotor speed directly affects the crushing kinetic energy. When processing hard materials, the speed can be appropriately increased (usually 1000-1200 r/min) to enhance impact and compression force; when processing brittle materials, the speed can be decreased (800-1000 r/min) to reduce over-crushing. In addition, the hydraulic system pressure should be checked regularly to ensure flexible discharge port adjustment. When slight blockage occurs, the discharge port can be quickly adjusted through the hydraulic system to remove the blocked material and restore normal operation.

C. Refined Maintenance: Ensuring Stable Output Efficiency

Wear of vulnerable parts and equipment malfunctions are the main causes of decreased efficiency in cone crushers. Establishing a comprehensive maintenance system can effectively extend the equipment's service life and maintain high-efficiency operation.

1. Regular Inspection and Replacement of Vulnerable Parts

The wear condition of vulnerable parts such as the crusher wall, jaw wall, and liners directly affects crushing efficiency. A regular inspection system must be established: check the wear of vulnerable parts weekly. When the wear exceeds 30% of the original size, promptly flip or replace them to avoid insufficient material crushing due to insufficient crushing force. For example, the high-manganese steel liner of the PYB-1750 cone crusher has a service life of approximately 800 hours, and the high-chromium alloy liner approximately 1500 hours. Regular replacement can keep the equipment's throughput above 90% of the design value. Simultaneously, check whether the liner fixing bolts are loose. If loose, tighten them promptly to prevent liner displacement, which can lead to uneven crushing chamber clearance, affecting crushing efficiency and product particle shape.

2. Lubrication and Cooling System Maintenance

Bearings are core components of the equipment and require adequate lubrication and effective cooling. For equipment with a centralized lubrication system, check the lubricating oil level daily, ensuring it is above the center line of the oil window. Use No. 32 or No. 46 gear oil and change it every 2000 hours of operation. Clean the oil tank and filter during replacement to prevent impurities from entering the bearings. When the ambient temperature exceeds 35℃, activate the cooling system to control the bearing temperature below 75℃ to prevent bearing seizure due to high temperatures. Additionally, regularly check lubrication lines for blockages and leaks, ensuring even oil supply to all lubrication points to reduce bearing wear and extend continuous equipment operating time.

3. Equipment Cleaning and Fault Prediction

After each day's operation, clean any residual material from the crushing chamber to prevent material from hardening and affecting the next day's start-up efficiency. Regularly check for dust accumulation inside the equipment and clean the heat sinks of components such as the motor and reducer to ensure good heat dissipation and prevent equipment shutdown due to overheating. Simultaneously, an intelligent monitoring system collects parameters such as motor current, bearing temperature, and vibration frequency in real time. When abnormal fluctuations occur (e.g., a sudden increase in current or intensified vibration), the machine is promptly shut down for troubleshooting, preventing minor issues from escalating into major malfunctions, reducing downtime, and increasing equipment uptime to over 90%.

D. Structural Upgrades and Technological Transformations: Breaking Through Efficiency Limits

For older equipment or high-requirement production scenarios, targeted structural upgrades and technological transformations can fundamentally improve the efficiency of cone crushers, achieving a dual improvement in both capacity and quality.

1. Core Component Upgrades and Optimizations

Replacing the traditional cast crushing wall with a forged composite crushing wall, employing a composite structure of "high-chromium alloy working layer + high-manganese steel matrix," ensures both wear resistance and good toughness, increasing service life by more than 2 times and crushing efficiency by 10-15%. Adding impact plates or optimizing the liner texture within the crushing chamber creates a multi-stage crushing process of "impact-extrusion-grinding," reducing over-crushing and improving the yield. For equipment handling viscous materials, spraying a ceramic wear-resistant coating onto the liner surface or installing polyurethane liners reduces the probability of material adhesion, decreases clogging and cleaning time, and improves processing efficiency.

2. Intelligent and Automated Upgrades: Installing an intelligent control system uses sensors to monitor parameters such as feed rate, crushing chamber pressure, and discharge particle size in real time, automatically adjusting the feed speed and discharge port size to maintain stable efficiency even with fluctuations in processing volume. For example, when the feed rate increases, the system automatically increases the rotor speed and widens the discharge port; when the feed rate decreases, it automatically decreases the speed and narrows the discharge port, ensuring the equipment is always in optimal operating condition. Simultaneously, variable frequency speed control technology is adopted to adjust the motor speed according to material characteristics and production capacity requirements, saving 15-20% energy compared to traditional fixed-speed motors and effectively preventing equipment overload.

3. Optimized Process Flow Combination

A combined process of "multi-stage crushing + grading and screening" is adopted, using a cone crusher in conjunction with a jaw crusher and a vibrating screen. The jaw crusher handles primary crushing, while the cone crusher handles secondary and fine crushing, avoiding overloading of any single piece of equipment. A vibrating screen is installed at the cone crusher discharge port to promptly separate materials of the appropriate particle size, preventing repeated crushing of qualified materials, reducing energy consumption, and improving overall processing efficiency. For example, an iron ore mine, through process optimization, changed its original two-stage crushing process of "jaw crusher + cone crusher" to a three-stage process of "jaw crusher + cone crusher + vibrating screen," increasing the processing capacity from 120t/h to 180t/h and reducing unit energy consumption by 25%. Furthermore, a rationally planned equipment layout shortens material transportation distances, reduces material loss and dwell time during transportation, and improves the overall efficiency of the production line.

Improving the crushing efficiency of cone crushers requires building a comprehensive optimization system encompassing "selection - operation - maintenance - modification." Scientific matching of material characteristics with equipment models is fundamental; standardized and uniform feeding and dynamic parameter adjustment can quickly improve efficiency; meticulous maintenance ensures stable output; and structural upgrades and process optimization expand long-term improvement potential. By working in tandem with these four strategies, pain points such as insufficient equipment output, excessive energy consumption, and short lifespan can be effectively addressed, significantly improving throughput and operational stability. These solutions balance practicality and economy, are applicable to production scenarios of different scales and operating conditions, and provide strong support for enterprises to reduce operating costs and enhance market competitiveness.

Save Time! Get A Detailed Quotation Quickly.