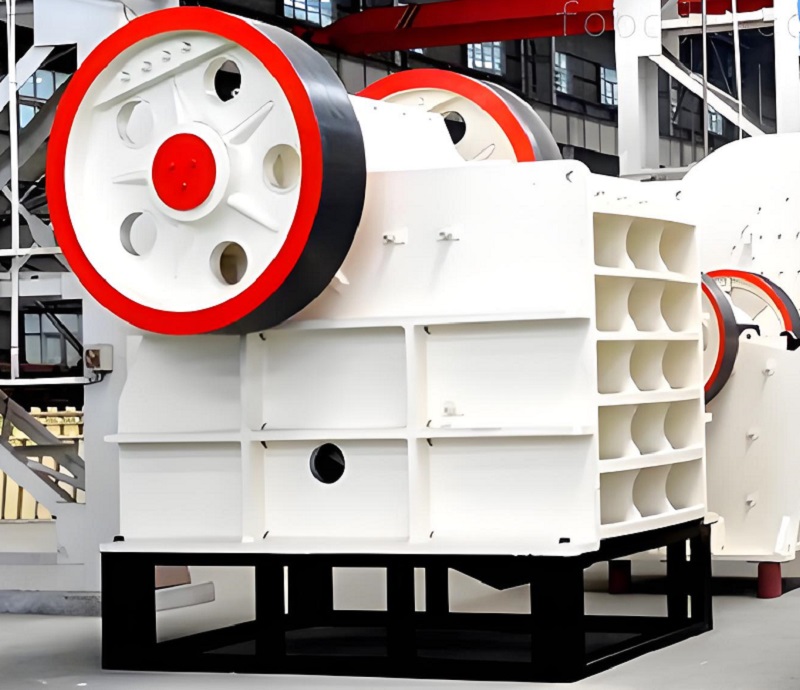

In mining, construction materials, and road infrastructure, crushing equipment is the core equipment for material processing, and its performance directly determines production efficiency, product quality, and overall economic benefits. The European-style jaw crusher, an upgraded product developed by integrating advanced European design concepts and manufacturing processes into traditional jaw crushers, has gradually become one of the mainstream equipment in the global crushing market due to its unique structural design, excellent crushing performance, and stable operation. Compared with traditional jaw crushers, the European-style jaw crusher has achieved breakthroughs in structural optimization, crushing efficiency, energy consumption control, and ease of maintenance. This article will systematically analyze the core competitiveness of the European-style jaw crusher from four dimensions: structural design characteristics, core performance advantages, applicable scenarios, and economic and environmental value, providing a reference for industry selection.

1. Structural Design Characteristics: Integrating European Concepts, Building a Solid Foundation for Stable Operation

The core advantage of the European-style jaw crusher stems from its refined structural design. Based on the core principle of "compression crushing" of traditional jaw crushers, it has undergone comprehensive optimization to address the pain points in the crushing process, forming a structural system that combines stability and high efficiency.

First, it adopts a heavy-duty frame and an optimized eccentric shaft design. The frame of the European-style jaw crusher is made of integral cast steel or high-strength steel plate welding, and undergoes aging treatment to eliminate internal stress, possessing higher rigidity and impact resistance, and can withstand the impact load of large-sized, high-hardness materials (such as granite, basalt, and iron ore). At the same time, the eccentric shaft is made of 42CrMo high-strength alloy steel, and undergoes heat treatment to improve wear resistance and fatigue resistance. The eccentricity can be flexibly adjusted according to crushing needs, achieving precise control of the crushing stroke. Compared with traditional jaw crushers, the frame thickness of the European-style jaw crusher is increased by 15%-25%, and the eccentric shaft diameter is increased by 10%-20%, significantly improving the operating stability of the equipment under heavy load conditions and effectively avoiding equipment failures caused by structural deformation.

Secondly, an innovative movable jaw and toggle plate connection structure. The European-style jaw crusher adopts an "integrated movable jaw" design, where the movable jaw plate and the movable jaw body are tightly connected by high-strength bolts, reducing the connection gap and improving the transmission efficiency of the crushing force. Simultaneously, the toggle plate adopts an optimized curved structure, resulting in a larger contact area with the movable jaw and frame, ensuring more even stress distribution and preventing toggle plate fracture caused by localized stress concentration. In addition, the equipment is equipped with elastic toggle plate pads, which not only cushion the impact load during the crushing process but also automatically break when the equipment is overloaded, providing overload protection and effectively protecting core components such as the motor and eccentric shaft from damage. This optimized connection structure increases the crushing force of the European-style jaw crusher by 20%-30%, while also reducing the wear rate of wear parts.

Finally, the modular and sealed design enhances adaptability. The European-style jaw crusher adopts a modular design concept, allowing for quick disassembly and replacement of core components such as the crushing chamber, toggle plate, and eccentric shaft, facilitating transportation, installation, and maintenance. At the same time, key parts of the equipment, such as the bearing housing, feed opening, and discharge opening, utilize a multi-layer sealing structure, combining labyrinth seals and dust seals to effectively prevent dust, moisture, and other impurities from entering internal components, reducing the risk of wear on bearings, gears, and other parts. Compared to traditional jaw crushers, the sealing performance of the European-style jaw crusher is significantly improved, extending the service life of bearings by more than 50% in dusty and high-humidity crushing environments.

2. Core Performance Advantages: High Efficiency and Energy Saving, Improving Crushing Processing Efficiency

Performance is the core competitiveness of the European-style jaw crusher. Its advantages in crushing efficiency, product quality, and energy consumption control directly bring significant economic benefits to users, meeting the development needs of the modern crushing industry for "high efficiency, energy saving, and refinement."

Firstly, high crushing efficiency and significantly increased throughput. The European-style jaw crusher optimizes the crushing chamber design, adopting a "deep cavity crushing" structure. The effective volume of the crushing chamber is increased by 30%-40%, allowing for larger feed material sizes and extending the material's residence time in the crushing chamber for thorough crushing. In addition, the eccentric shaft speed of the equipment is precisely calculated, increasing by 15%-25% compared to traditional jaw crushers, resulting in a higher crushing frequency and faster material crushing speed. When processing materials of the same hardness and particle size, the throughput per unit time of the European-style jaw crusher can be increased by 20%-50%. For example, when processing granite with a particle size of ≤800mm, the PE-900×1200 European-style jaw crusher can achieve a processing capacity of 150-280 tons/hour, far exceeding the 100-200 tons/hour of traditional jaw crushers of the same specifications.

Secondly, the product quality is superior, with uniform particle shape and reasonable gradation. The crushing chamber of the European-style jaw crusher adopts a "tapered" design. From the feed opening to the discharge opening, the crushing gap gradually decreases. The material undergoes multiple compressions and grinding during the crushing process, resulting in a more regular particle shape and significantly reduced needle-like and flaky content. At the same time, the equipment is equipped with an adjustable discharge opening device. Through a wedge-type or hydraulic adjustment mechanism, precise control of the discharge particle size can be achieved, adapting to the different particle size requirements of various applications (such as building aggregates requiring particle size ≤50mm, and road subbase requiring particle size ≤31.5mm). Actual measurements show that the needle-like and flaky content of the product crushed by the European-style jaw crusher is less than 10%, far superior to the 15%-20% of traditional jaw crushers. The product gradation is more reasonable, and it can be used directly without additional shaping treatment, enhancing the product's market competitiveness.

Thirdly, it offers significant energy savings and reduced operating costs. The European-style jaw crusher adopts an optimized transmission system, where the motor and eccentric shaft are directly connected through a V-belt or coupling, increasing the transmission efficiency to over 95% and reducing energy loss. At the same time, the crushing force of the equipment is more reasonably matched with the motor power, improving crushing efficiency while reducing energy consumption per unit of material by 10%-20% compared to traditional jaw crushers. Taking a production line with a processing capacity of 200 tons/hour as an example, the motor power of the European-style jaw crusher is 160kW, while a traditional jaw crusher requires more than 200kW. This saves approximately 960 kWh of electricity per day, resulting in annual electricity cost savings of hundreds of thousands of yuan. In addition, the wear parts of the equipment (such as jaw plates, toggle plates, and liners) are made of high-quality wear-resistant materials such as high-chromium alloy and wear-resistant cast iron, and the surface is hardened, increasing wear resistance by 30%-50%, reducing the frequency of parts replacement and further lowering operating costs. 3. Application Scenario Adaptation: Compatible with Diverse Working Conditions, Expanding the Boundaries of Industry Applications

The European-style jaw crusher, with its stable operating performance, wide feed range, and flexible adjustment capabilities, can adapt to a variety of complex crushing conditions and is widely used in mining, construction demolition waste treatment, road infrastructure, cement and building materials, and many other industries, demonstrating strong adaptability to various scenarios.

In the mining industry, the European-style jaw crusher is a core piece of equipment in the primary crushing stage, capable of processing various high-hardness materials such as granite, basalt, iron ore, and limestone. Its heavy-duty structural design can withstand the impact of large-sized materials at mining sites, and its stable operating performance ensures continuous production, effectively improving the efficiency of mining operations. For example, in granite mining, the European-style jaw crusher can crush raw ore with a particle size of ≤1000mm to semi-finished products of ≤150mm, providing qualified raw materials for subsequent medium and fine crushing processes. At the same time, the modular design of the equipment facilitates transportation and installation in complex mining terrains, allowing for open-pit or underground operations, adapting to different mining environments.

In the field of construction demolition waste treatment, the European-style jaw crusher demonstrates strong adaptability. Construction demolition waste is complex in composition, containing various materials such as concrete blocks, bricks, rebar, and wood, which can easily cause blockages and jamming in traditional crushing equipment. The deep crushing chamber and large stroke design of the European-style jaw crusher effectively prevent material blockages, while the overload protection function of the elastic toggle plate prevents damage to the equipment from hard objects such as rebar. Through crushing with the European-style jaw crusher, construction demolition waste can be transformed into recycled aggregate, used for road subgrades, concrete products, etc., achieving resource recycling. For example, at urban demolition sites, mobile European-style jaw crushers can be directly deployed to the site to crush demolition waste on-site, reducing waste transportation costs and aligning with the environmental concept of "on-site processing and resource recycling."

In the fields of road infrastructure and cement and building materials, the European-style jaw crusher can provide high-quality construction aggregates for projects. Road construction requires strict specifications for aggregate particle shape and gradation. The European-style jaw crusher produces aggregates with uniform particle shape and low needle-like and flaky content, which can be directly used in the preparation of asphalt concrete and cement concrete, improving the quality of road engineering. In cement production, the European-style jaw crusher can crush raw materials such as limestone to a suitable particle size, providing high-quality raw materials for subsequent grinding processes and improving cement production efficiency. Furthermore, the European-style jaw crusher can be combined with cone crushers, impact crushers, vibrating screens, and other equipment to form a complete crushing production line, achieving integrated processing from raw material crushing to finished product classification, adapting to different production scales.

4. Economic and Environmental Value: Significant Cost Reduction and Efficiency Improvement, Aligned with Green Development Concepts

The advantages of the European-style jaw crusher are not only reflected in direct production efficiency and operating costs, but also demonstrate outstanding competitiveness in long-term economic benefits and environmental value, aligning with the modern industrial development concept of "green, efficient, and sustainable."

From an economic perspective, the European-style jaw crusher brings significant overall benefits to users by improving crushing efficiency and reducing energy consumption and maintenance costs. On the one hand, the high processing capacity of the equipment increases the overall capacity of the production line, allowing for the processing of more materials in the same amount of time and increasing product output; on the other hand, the high-quality product improves the selling price and enhances market competitiveness. At the same time, the low energy consumption and low wear and tear of the equipment reduce the processing cost per unit of material, further increasing profit margins. Taking a production line with an annual output of 1 million tons of construction aggregate as an example, using a European-style jaw crusher instead of a traditional jaw crusher can save approximately 500,000-800,000 RMB in energy and maintenance costs annually, while the product qualification rate increases by more than 10%, resulting in an additional income of approximately 1-1.5 million RMB. The economic benefits are very significant. In addition, the European-style jaw crusher has a longer service life, with an average service life of 8-10 years, far exceeding the 5-6 years of traditional jaw crushers, reducing equipment replacement costs and improving long-term return on investment.

From an environmental perspective, the European-style jaw crusher reduces its environmental impact through multiple design features, complying with environmental protection policies. Firstly, the equipment boasts excellent sealing performance. The sealing covers and dust-proof devices at the feed and discharge ports effectively prevent dust diffusion. Combined with auxiliary dust removal equipment such as pulse dust collectors, the dust concentration at the work site can be controlled below 10 mg/m³, meeting the requirements of the "Comprehensive Emission Standard for Air Pollutants." Secondly, the equipment operates with low noise. Through optimized transmission structures and added sound insulation devices, the operating noise level is below 85 decibels, reducing noise pollution's impact on the surrounding environment and workers. Finally, the application of European-style jaw crushers in resource recycling fields such as construction demolition waste and mine tailings can effectively reduce landfill volume and resource waste, promoting the development of a circular economy. For example, after crushing construction demolition waste with a European-style jaw crusher, the recovery rate of recycled aggregates can reach over 80%, significantly reducing the land occupied by landfills and simultaneously reducing the mining of natural aggregates, thus protecting the ecological environment.

With its heavy-duty structural design, high-efficiency and energy-saving performance, wide range of applications, and significant economic and environmental value, the European-style jaw crusher has become the preferred equipment for upgrading the crushing industry. Integrating advanced European concepts and manufacturing processes, it effectively solves the problems of poor stability, low efficiency, high energy consumption, and high pollution associated with traditional jaw crushers under heavy-duty conditions, providing efficient and green crushing solutions for mining, infrastructure construction, and resource recycling. As global industry demands for crushing equipment continue to increase, the European-style jaw crusher will continue to make breakthroughs in intelligent upgrades (such as remote monitoring and automatic adjustment), material optimization (such as more wear-resistant composite materials), and further energy consumption reduction, providing stronger support for the green and high-quality development of the crushing industry. For enterprises, choosing a European-style jaw crusher not only improves production efficiency and product quality but also reduces operating costs and enhances environmental competitiveness, achieving a win-win situation in both economic and social benefits.

Save Time! Get A Detailed Quotation Quickly.