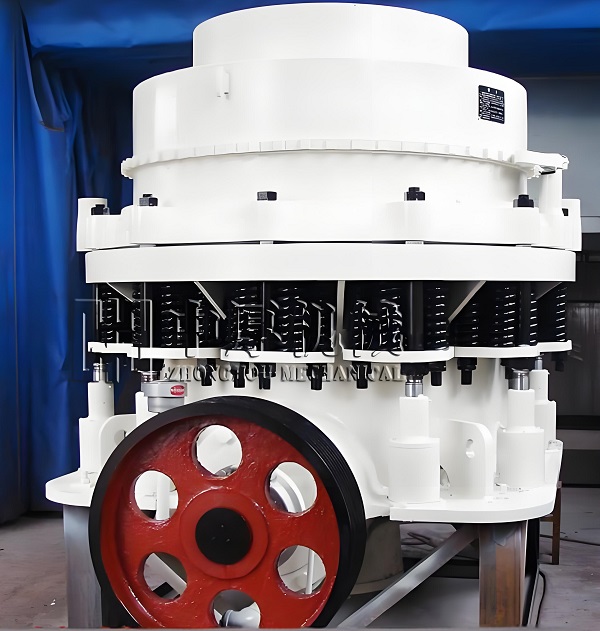

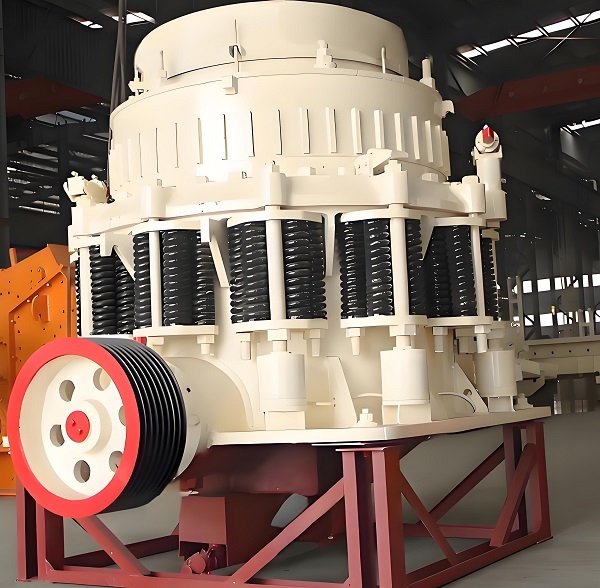

Introduction: The spring cone crusher, also known as the PY spring cone crusher, is primarily used for medium and fine crushing of materials with medium to high hardness, such as concrete, basalt, granite, river pebbles, iron ore, etc. It is widely applied in industries like environmental protection, metallurgy, building materials, and mining. The spring cone crusher possesses unique structural advantages and characteristics that cater to the needs of crushing operations.

A. Product advantages of spring cone crushers:

1. High production efficiency: The adoption of a hydraulic cavity cleaning system and iron overload protection reduces downtime for fault repairs, thereby enhancing production efficiency.

2. High equipment configuration: The hydraulic system not only provides iron protection but also allows for quick cleaning of the crushing chamber. Additionally, the components of the device are easy to disassemble and install.

3. High safety performance: The non-contact labyrinth seal is adopted, which has a low wear rate, improves the reliability of dust prevention, and enhances the safety performance of the equipment.

4. Easy adjustment: Strong crushing capacity, easy adjustment of the ore discharge opening, and flexible adjustment based on specific particle size requirements.

B. Working principle of spring cone crusher:

When the spring-loaded cone crusher is in operation, the eccentric sleeve is rotated by the motor through the V-belt, large pulley, transmission shaft, small bevel gear, and large bevel gear. Under the force of the eccentric sleeve, the crushing cone's axial line rotates and oscillates, causing the crushing wall surface to intermittently approach and move away from the surface of the bowl wall. This process continuously subjects the material to impact, compression, and bending within the annular crushing chamber formed by the fixed cone and the moving cone, resulting in crushing. After multiple compressions, impacts, and bends, the material is crushed to the desired particle size and discharged through the lower part.

The spring cone crusher crushes ore using the working surface between the movable cone and the stationary cone. The movable cone is supported on a spherical bearing and fixed to a suspended vertical shaft, which is placed inside an eccentric sleeve. The eccentric sleeve is in turn placed on a thrust bearing. The movable cone and the vertical shaft are driven together by an eccentric shaft sleeve, which is driven by a horizontal shaft, pulley, and bevel gear. The pulley is driven by an electric motor through a V-belt. The lower part of the vertical shaft is fitted into the eccentric sleeve. When the eccentric sleeve rotates, it draws out a conical surface with the shaft. Therefore, when the movable cone approaches the stationary cone, the ore is crushed.

C. Structural characteristics of spring cone crusher

The spring cone crusher is primarily composed of a frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, adjustment device, adjustment sleeve, spring, and hydraulic station for adjusting the discharge opening. The spring cone crusher (PY series) boasts a perfect combination of high-performance crushing chamber and high crushing frequency, significantly enhancing crushing capacity. Additionally, it incorporates the laminar crushing principle, effectively reducing needle-like and flaky materials to a certain extent. The spring safety system serves as an overload protection device, providing "spring-type" iron release protection for foreign objects (iron pieces). Under normal usage conditions, the equipment operates without failure for over 95% of the time.

D. Structural advantages of spring cone crusher:

1. The presence of safety devices significantly reduces downtime.

2. The body is made of cast steel structure, with reinforcing ribs provided at the heavy-load areas.

3. Equipped with an adjuster, it can quickly adjust the size of the crushed material output.

4. Provide a spring-type protective device.

5. Equipped with a complete lubrication system, it will automatically shut down when the temperature is too high or the flow rate is too slow.

6. The internal structure boasts excellent sealing performance, effectively protecting the equipment from dust and other small particles.

7. It has a long service life and strong applicability.

Technical Parameter:

| Model | Feed particle size (mm) | Adjustable range of discharge port (mm) | Processing capacity (t/h) | Motor power (kw) | External dimensions (mm) |

| ZCB600 | 65 | 12-25 | 10-25 | 30 | 2234×1370×1675 |

| ZCD600 | 35 | 3-13 | 5-20 | 30 | 2234×1370×1675 |

| ZCB900 | 115 | 15-50 | 50-90 | 55 | 2692×1640×2350 |

| ZCB1200 | 145 | 20-50 | 110-168 | 110 | 2790×1878×2844 |

| ZCZ1200 | 100 | 8-25 | 42-135 | 110 | 2790×1878×2844 |

| ZCZ1750 | 185 | 10-30 | 115-320 | 160 | 3910×2894×3809 |

| ZCD1750 | 85 | 5-15 | 75-230 | 160 | 3910×2894×3809 |

| ZCD2200 | 100 | 5-15 | 120-340 | 260/280 | 4622×3302×4470 |

PS: The spring cone crusher is an excellent crushing equipment that can meet various crushing needs. With its high efficiency, reliability, and flexibility, the spring cone crusher has been widely used and recognized in practical applications.

Save Time! Get A Detailed Quotation Quickly.