Preface: Cone crusher, the first choice for efficient crushing, leads the new trend in the crushing industry with excellent performance and stable quality. It adopts advanced crushing technology to easily handle various hardness materials, achieving efficient and precise crushing operations. This article introduces the classification and selection techniques of cone crushers:

A. Types of cone crushers

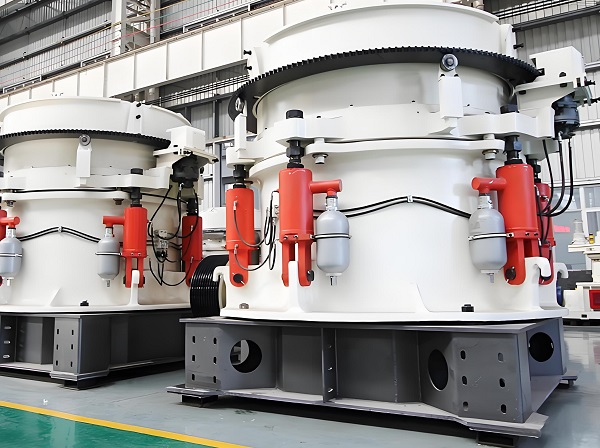

Cone Crusher

Cone crusher is an efficient crushing equipment widely used in environmental protection, mining, smelting, construction, highway, building materials, chemical industry, mining and coal fields. The following are the main models of cone crushers and their differences:

1. Single cylinder cone crusher

Model: Common models of single cylinder cone crushers include DG series and HST series. characteristic:

a. Simple structure and convenient operation.

b. Equipped with an electronic intelligent ore discharge control system, it can achieve precise production process control and operation optimization.

c. Large production capacity, high crushing efficiency, and low energy consumption.

d. Suitable for medium crushing operations, with large feed particle size and strong processing capacity.

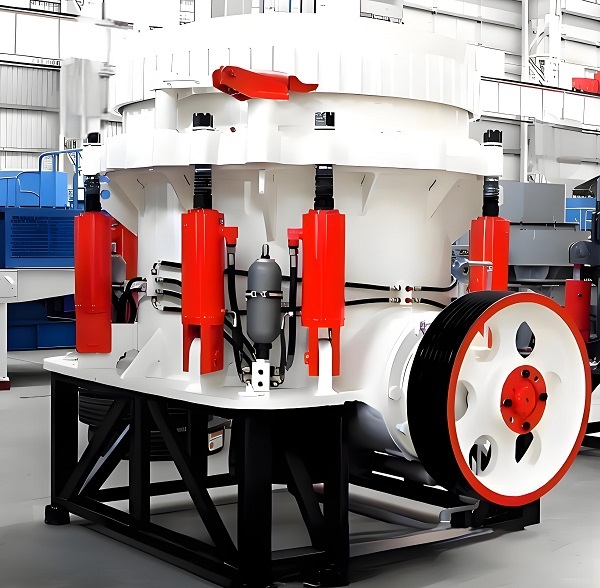

2. Multi cylinder cone crusher

Cone Crusher

Model: Common models of multi cylinder cone crushers include the HPT series (such as HPT100, HPT300, HPT800, etc.). characteristic:

a. By adopting advanced crushing frequency and eccentricity, selective crushing of materials can be achieved, with good particle shape and reasonable grading.

b. The hydraulic cone crusher is integrated with a hydraulic protection system, which can achieve higher safety and efficiency, and support automated operation.

c. Equipped with a hydraulic cleaning system, it reduces equipment downtime.

d. We offer a variety of crushing chamber types to meet different needs, suitable for medium and fine crushing processing, with finer discharge.

3. Spring cone crusher

Cone Crusher

Model: Common spring cone crusher models include PY series and CS series. characteristic:

a. Spring cone crusher is one of the earlier cone crushers on the market, with a relatively simple structure.

c. According to the purpose of the ore, it can be divided into different crushing chamber types. The standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for extra fine crushing.

c. Suitable for crushing various ores and rocks with medium and above hardness (below 350 megapascals).

4. Other cone crushers

Cone Crusher

a. Simmons cone crusher: also known as a type of spring cone crusher, it has the characteristics of the spring cone crusher mentioned above.

b. Hydraulic cone crusher: In addition to the HPT series, there are other brands of hydraulic cone crushers that share the common feature of incorporating hydraulic protection systems to improve safety and efficiency.

5. Summary of Model Differences

a. Structural differences: Single cylinder cone crushers have relatively simple structures, while multi cylinder cone crushers and spring cone crushers have more complex structures but provide more functionality and adaptability.

b. Processing capability: Different models of cone crushers have different processing capabilities, and users can choose the appropriate model according to their actual needs.

c. Applicable scenarios: Single cylinder cone crushers are suitable for intermediate crushing operations, multi cylinder cone crushers are suitable for intermediate and fine crushing processing, while spring cone crushers can choose different crushing chamber types according to the purpose of the ore.

There are various models of cone crushers, each with its own characteristics. Users should consider factors such as actual needs, material properties, and production capacity when making a selection, and choose the most suitable model.

B. Precautions for selecting a cone crusher

When choosing a cone crusher, multiple factors need to be considered to ensure the selection of the most suitable equipment for your production needs. Here are some key precautions:

Cone Crusher

1. Material characteristics

a. Hardness: Materials with high hardness require stronger crushing force to achieve the expected effect. Therefore, for materials with high hardness, high-power and large cone crushers should be selected.

b. Humidity: Materials with high humidity will increase the energy consumption of the crusher and may cause equipment failure. Therefore, for materials with high moisture content, it is necessary to choose a durable cone crusher and determine the appropriate outlet position to avoid excessive moisture entering the equipment interior.

2. Crushing requirements

a. Particle size: Products in different fields have different requirements for crushing particle size. For example, in the construction material processing industry, relatively small particles are generally required; In the mining industry, larger particles may be required. Therefore, when choosing a cone crusher, it is necessary to clarify one's product quality requirements and select suitable equipment according to actual needs.

b. Output: The production capacity of a cone crusher is closely related to its parameters such as power, speed, and discharge port. If a large amount of materials need to be processed, it is necessary to choose equipment with high production capacity.

3. Equipment performance

a. Automation level: A highly automated cone crusher can save time, effort, cost, and improve work efficiency.

b. Overload protection device: Cone crushers equipped with overload protection devices can allow foreign material blocks to pass through the crushing chamber without harming the machine, thereby extending the service life of the equipment.

c. Adjustment convenience: A good cone crusher needs to be easy to adjust, with parameters that can be adjusted according to actual production needs at any time, and ensure stable equipment performance after adjustment without affecting product quality.

4. Brand and Manufacturer

Cone Crusher

a. Brand: Well known cone crushers usually have high cost-effectiveness and reliability, but prices may also be relatively high. When making a purchase, you can choose based on your budget and needs.

b. Manufacturer: Choosing a reputable manufacturer can ensure that all indicators of the equipment comply with relevant national regulations and that the equipment quality is guaranteed. In addition, well-known manufacturers have advanced production technology and rich production experience, which can provide users with better after-sales service.

5. Price and maintenance costs

a. Price: Price is one of the important factors that affect purchasing decisions. When making a purchase, multiple factors need to be considered, including cost investment, market conditions, economic dynamics, etc. Excessively high prices may lead to excessive profits for manufacturers, while excessively low prices may mean that equipment quality is not guaranteed.

b. Maintenance cost: Cone crushers of different brands and models have varying levels of difficulty in maintenance. When selecting, it is necessary to choose equipment that is easy to maintain and repair, and conduct regular maintenance and overhaul to ensure the normal operation of the equipment.

6. Safety and environmental performance

a. Safety: The cone crusher needs to ensure the safety of operators during operation. Therefore, when purchasing, it is necessary to pay attention to whether the safety protection measures of the equipment are complete.

b. Environmental performance: With the increasing awareness of environmental protection, more and more companies are paying attention to the environmental performance of their equipment. When choosing a cone crusher, it is important to pay attention to whether it meets national environmental standards and whether excessive noise and dust pollutants are generated during use.

In summary, when choosing a cone crusher, multiple factors need to be considered, including material characteristics, crushing requirements, equipment performance, brand and manufacturer, price and maintenance costs, as well as safety and environmental performance. Only by comprehensively considering these factors can one choose the equipment that best suits their production needs.

Technical parameters of cone crusher

| ZCS51B | Fine type | one hundred and fifteen | 13~31 | 109~181 | one hundred and sixty | twenty-six point five | 2958×2354×3156 |

| medium-sized | 178 | 16~38 | 132~253 | 160 | 26.5 | 2958×2354×3156 | |

| Coarse type | 205 | 19~51 | 172~349 | 160 | 26.5 | 2958×2354×3156 | |

| Extra coarse type | 220 | 25~51 | 236~358 | 160 | 26.5 | 2958×2354×3156 | |

| ZCS51D | Fine type | 54 | 3~16 | 36~163 | 160 | 27 | 2958×2354×3156 |

| medium-sized | 76 | 6~16 | 82~163 | 160 | 27 | 2958×2354×3156 | |

| Coarse type | 89 | 8~25 | 109~227 | 160 | 27 | 2958×2354×3156 | |

| Extra coarse type | 113 | 16~25 | 209~236 | 160 | 27 | 2958×2354×3156 | |

| ZCS66B | Fine type | 178 | 16~38 | 181~327 | 220 | 51 | 3941×2954×3771 |

| medium-sized | 205 | 22~51 | 258~417 | 220 | 51 | 3941×2954×3771 | |

| Coarse type | 228 | 25~64 | 299~635 | 220 | 51 | 3941×2954×3771 | |

| Extra coarse type | 313 | 38~64 | 431~645 | 220 | 51 | 3941×2954×3771 | |

| ZCS66D | Fine type | 60 | 5~13 | 90~209 | 220 | 52 | 3941×2954×3771 |

| medium-sized | 76 | 6~19 | 136~281 | 220 | 52 | 3941×2954×3771 | |

| Coarse type | 113 | 10~25 | 190~336 | 220 | 52 | 3941×2954×3771 | |

| Extra coarse type | 125 | 13~25 | 253~336 | 220 | 52 | 3941×2954×3771 | |

| ZCS84B | Fine type | 236 | 19~38 | 381~726 | 315 | 90 | 4613×3251×4732 |

| medium-sized | 284 | 25~51 | 608~998 | 315 | 90 | 4613×3251×4732 | |

| Coarse type | 314 | 31~64 | 789~1270 | 315 | 90 | 4613×3251×4732 | |

| Extra coarse type | 391 | 38~64 | 880~1361 | 315 | 90 | 4613×3251×4732 |

PS: The cone crusher has a reasonable design, compact structure, small footprint, and is easy to install and maintain. At the same time, it is equipped with an intelligent control system, which is easy to operate and can monitor the real-time operation status of equipment to ensure production safety and stability. Whether in environmental protection, mining, construction or other fields, our cone crushers can demonstrate excellent crushing effects and help you achieve your production goals. Choosing our cone crusher means choosing an efficient, stable, and reliable production partner.

Save Time! Get A Detailed Quotation Quickly.