Cone crushers play a crucial role in garbage recycling, especially in construction waste recycling. The following is a detailed analysis of the role of cone crushers in garbage recycling:

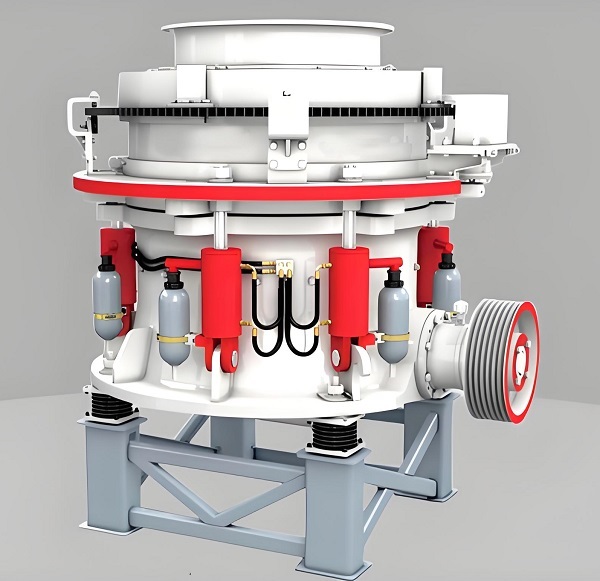

Cone Crusher

1. Working principle of cone crusher

The cone crusher is mainly composed of a moving cone, a fixed cone, an eccentric shaft, a distribution plate, and other parts, which crush materials through rotation and compression. After the material enters the crushing chamber, it is evenly distributed by the distribution plate, and the moving cone rotates on the inner surface of the fixed cone under the drive of the eccentric shaft. When the surface of the moving cone is close to the inner surface of the fixed cone, the material here is crushed by compression, bending, and grinding, and the crushed material is discharged from the discharge port at the bottom of the cone. Work continuously until all materials are crushed and discharged.

Cone Crusher

2. Application of cone crusher in construction waste recycling

a. Crushed recycled aggregate: The cone crusher can crush discarded construction waste such as concrete blocks and bricks and regenerate them into aggregates. These aggregates can replace natural sand and gravel for non load bearing parts in cast-in-place or prefabricated concrete components, saving natural resources and reducing construction costs.

b. Production of recycled building materials: The recycled aggregates from construction waste crushed by a cone crusher can also be used to produce high value-added products such as recycled bricks, recycled concrete, insulation materials, insulation walls around walls, and dry mixed mortar. These recycled building materials not only meet the quality standards, but also have good sound insulation, heat insulation and other properties, meeting the market's demand for green building materials.

c. Dry wet separation and metal separation: Some cone crushers (such as cone crushers) also have the functions of dry wet separation and metal separation. During the crushing process, moisture and impurities in the material can be separated through a material cleaner and screening screen, while also separating metals and non metals, further improving the reuse rate of waste materials.

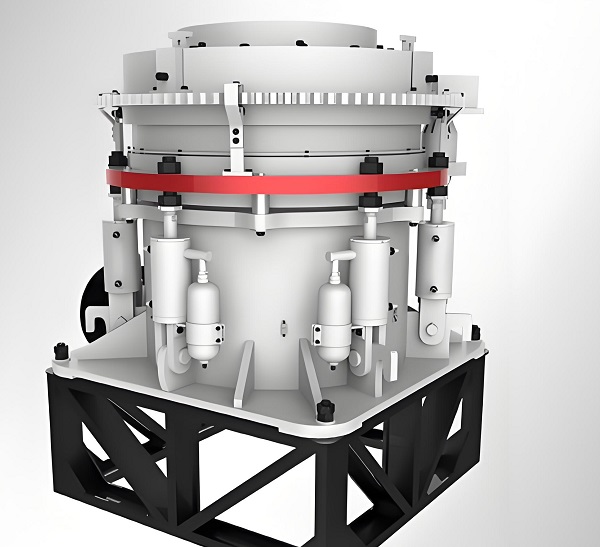

Cone Crusher

3. Advantages of cone crusher

a. Efficient and energy-saving: The cone crusher adopts advanced crushing technology and design, which can achieve efficient crushing and also has obvious advantages in energy saving.

b. Strong adaptability: The cone crusher is suitable for various types of construction waste and waste materials, such as concrete blocks, bricks, scrap metals, etc., and has strong adaptability.

c. Easy to operate: The operation of the cone crusher is relatively simple and does not require professional skills. It only needs to be operated correctly according to the instructions.

d. Easy maintenance: The cleaning and maintenance of the cone crusher are also very convenient, which can effectively reduce the maintenance cost of the equipment and improve its service life.

Cone Crusher

The significance of cone crusher in garbage recycling

a. Environmental significance: The application of cone crushers effectively solves the problem of stacking and pollution of waste materials such as construction waste, promotes the recycling of resources, and reduces environmental pollution.

b. Economic significance: Through the crushing and recycling of cone crushers, waste materials can be transformed into valuable recycled building materials, providing abundant building material resources for the market and creating economic benefits for enterprises.

Technical parameters of cone crusher

| model | Cavity type | Maximum feed particle size (mm) | Adjustment range of discharge port (mm) | Output (t/h) | Motor power (kw) | Weight (t) |

| ZCC600 | C | 95 | 10-38 | 20-76 | 30-37 | 5.3 |

| M | 72 | 6-38 | 18-60 | 30-37 | 5.3 | |

| ZCC1000 | C | 160 | 13-38 | 80-235 | 90-110 | 10.8 |

| M | 115 | 10-25 | 65-150 | 90-110 | 10.8 | |

| F | 80 | 6-19 | 52-115 | 90-110 | 10.51 | |

| EF | 50 | 6-19 | 50-102 | 90-110 | 10.51 | |

| ZCC1200 | C | 180 | 13-38 | 115-260 | 110-132 | 15.5 |

| M | 130 | 10-25 | 100-175 | 110-132 | 15.5 | |

| F | 90 | 10-19 | 80-140 | 110-132 | 15.5 | |

| EF | 60 | 6-19 | 60-130 | 110-132 | 15.5 | |

| ZCC1300 | C | 200 | 16-51 | 150-390 | 185-200 | 24.1 |

| M | 150 | 13-25 | 115-210 | 185-200 | 24.1 | |

| F | 102 | 10-19 | 90-160 | 185-200 | 24.1 | |

| EF | 70 | 8-19 | 80-155 | 185-200 | 24.1 | |

| ZCC1400 | C | 215 | 19-51 | 200-440 | 200-220 | 26.3 |

| M | 160 | 16-25 | 155-230 | 200-220 | 26.3 | |

| F | 115 | 13-22 | 150-230 | 200-220 | 26.3 | |

| EF | 76 | 10-19 | 122-200 | 200-220 | 26.3 | |

| ZCC1650 | C | 235 | 22-64 | 265-580 | 220-250 | 37.75 |

| M | 175 | 19-38 | 215-330 | 220-250 | 37.75 | |

| F | 130 | 13-25 | 180-285 | 220-250 | 37.75 | |

| EF | 90 | 10-19 | 148-220 | 220-250 | 37.75 | |

| ZCC1950 | C | 267 | 22-64 | 330-725 | 280-315 | 59.6 |

| M | 203 | 16-25 | 230-330 | 280-315 | 59.6 | |

| F | 140 | 13-22 | 185-340 | 280-315 | 59.6 | |

| EF | 95 | 10-19 | 180-335 | 280-315 | 59.6 |

In summary, cone crushers play a crucial role in garbage recycling, not only promoting resource recycling and reducing environmental pollution, but also creating economic benefits for enterprises, promoting green building and sustainable development.

Save Time! Get A Detailed Quotation Quickly.