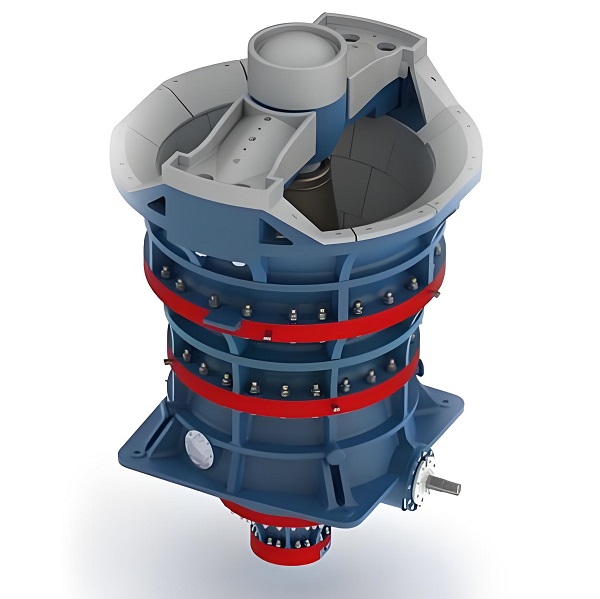

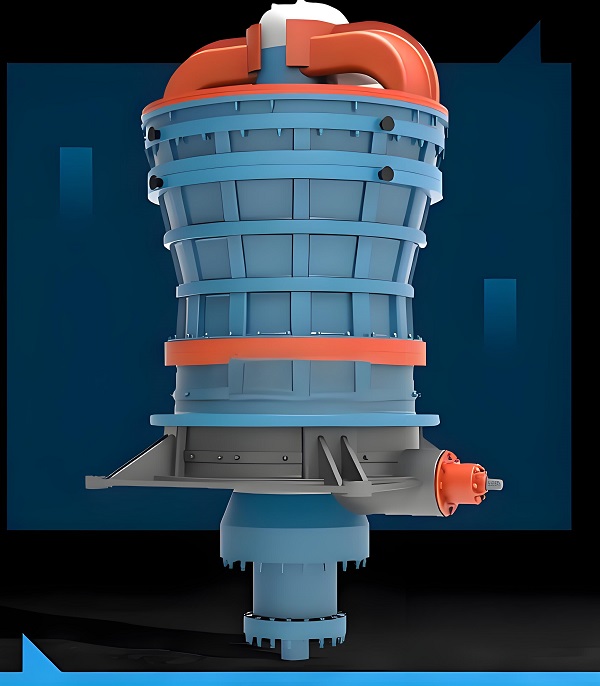

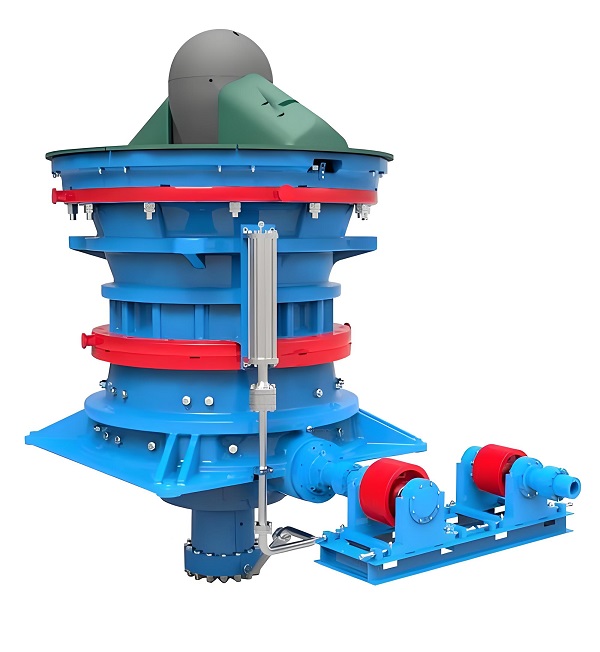

Preface: Rotary crusher is a heavy-duty crushing equipment widely used in environmental protection, mining, metallurgy, building materials and other fields. Its main characteristics are high crushing ratio, high yield, and uniform particle size, suitable for processing various hard and highly abrasive ores and concrete. The gyratory crusher can meet the efficient processing needs of a large amount of raw materials and plays an important role in crushing, improving production efficiency and reducing production costs.

A. Precautions for selecting a gyratory crusher:

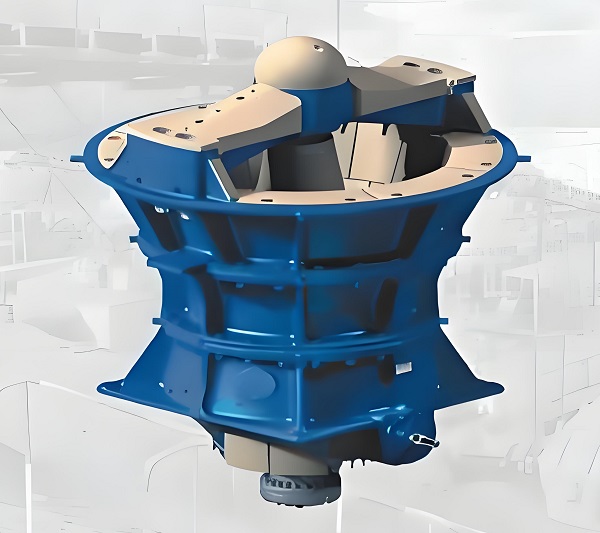

The gyratory crusher is a type of cone crusher mainly used for coarse crushing of ores. It crushes various ores by squeezing, splitting, and bending materials. When choosing a gyratory crusher, the following key factors need to be considered:

1. Adaptability and functionality

a. Material type: The gyratory crusher is suitable for processing ores and rocks of various hardness, such as river pebbles, granite, iron ore, limestone, etc. When selecting, it is necessary to ensure that the crusher can handle the type of material that needs to be crushed.

b. Processing capacity: Determine the processing capacity of the crusher based on production needs, that is, the amount of material that can be processed per hour. The processing capacity of a gyratory crusher is usually high, but the specific model and specifications may vary.

2. Power and efficiency

a. Power source: The power of hydraulic gyratory crushers usually comes from the hydraulic system of excavators or other power sources. It is necessary to ensure that the power source of the selected crusher can provide sufficient power to meet production needs.

b. Work efficiency: The rotary crusher has high work efficiency and low unit power consumption. When choosing, you can compare the working efficiency of different models and specifications of crushers and choose products with higher cost-effectiveness.

3. Durability and maintenance

a. Equipment quality: The structure of the gyratory crusher is complex and difficult to manufacture, so equipment quality is crucial. When making a purchase, it is advisable to choose products produced by reputable manufacturers to ensure reliable equipment quality.

b. Maintenance cost: The maintenance cost of a gyratory crusher includes repair costs, replacement parts costs, etc. When making a purchase, you can understand the maintenance costs of different brands and models of crushers and choose products with lower maintenance costs.

4. Safety and ease of operation

a. Safety: The operation of a gyratory crusher requires certain skills and experience, so safety is crucial. When purchasing, it is advisable to choose products with comprehensive safety protection measures, such as overload protection, automatic shutdown, etc.

b. Ease of operation: With the development of technology, some gyratory crushers have been equipped with automated control systems, which can improve the safety and convenience of operation. When making a purchase, you can understand the ease of operation of the product and choose products that are easy to operate.

5. Other factors

a. After sales service: When choosing a gyratory crusher, the quality of after-sales service should also be considered. Legitimate manufacturers usually provide comprehensive after-sales service, including equipment installation, debugging, maintenance, etc.

b. Price factor: The price of a gyratory crusher varies depending on factors such as model, specifications, and brand. When making a purchase, you can choose suitable products based on your budget and actual needs.

Choosing a gyratory crusher requires comprehensive consideration of adaptability and functionality, power and efficiency, durability and maintenance, safety and ease of operation, as well as other factors. By comprehensively comparing products of different brands and models, one can choose the product that best suits their production needs.

B. Advantages of Zhongcheng Machinery's gyratory crusher:

1. Strong crushing ability: Due to the repeated crushing and shaping of materials in the crushing chamber, the gyratory crusher has strong crushing ability.

2. High productivity: The crushing process is continuous, so the productivity of the gyratory crusher is also high.

3. Compact structure: The equipment has a compact structure, high strength, and can adapt to harsh working environments.

4. Easy to maintain: Advanced lubrication system and electrical control system are adopted to ensure the stability and reliability of equipment operation, while also facilitating maintenance and upkeep.

In addition, the gyratory crusher is also suitable for fields such as construction waste treatment and concrete recycling. Through efficient crushing processing, it achieves resource recycling and reduces environmental pollution.

C. Disadvantages of gyratory crusher:

The gyratory crusher also has some shortcomings, due to its relatively complex structure, high price, difficult maintenance, and relatively high repair costs. In addition, the higher body of the aircraft increases the cost of factory and infrastructure construction.

Technical parameters of gyratory crusher

| model | Feed inlet size (mm) | Maximum feed particle size (mm) | Adjustment range of discharge outlet (mm) | Processing ability (t/h) | Motor power (kw) | External dimensions Length x Width x Height (mm) |

| ZCXH4265 | one thousand and sixty-five | nine hundred | 140-175 | 2018-2878 | four hundred | 3940×4170×6900 |

| ZCXH5065 | one thousand two hundred and seventy | one thousand and fifty | 150-175 | 2403-2943 | four hundred | 4460×4430×7610 |

| ZCXH5475 | one thousand three hundred and seventy | one thousand one hundred and fifty | 150-200 | 2893-3493 | four hundred and fifty | 4930×4925×8410 |

| ZCXH6275 | one thousand five hundred and seventy-five | one thousand three hundred and fifty | 150-200 | 2898-4338 | four hundred and fifty | 5580×5250×9090 |

| ZCXH6089 | one thousand five hundred and twenty-five | one thousand and three hundred | 165-230 | 4203-5813 | six hundred and thirty | 5590×5445×10470 |

| ZCXH60110 | one thousand five hundred and twenty-five | one thousand and three hundred | 175-250 | 5543-8898 | one thousand two hundred and fifty | 6200×5940×11390 |

D. Prospect of gyratory crusher

Faced with the arrival of the peak period of high-speed railway construction in China, the demand for composite crushers in the market is particularly strong. However, due to the construction of high-speed railways, the requirements for sand and concrete aggregates are relatively high, and there are at least ten large enterprises in the composite crusher industry that have the production capacity to meet this demand. Composite crushers have been widely installed in the construction of highways and high-speed railways in various provinces and cities across the country, and are indispensable equipment for national infrastructure. For the crushing of basalt, the stone material crushed by the composite crusher can be reduced to about 4% in needle like content after being crushed by the impact crusher, making it an ideal composite crusher equipment in the production process of sand and gravel aggregates.

Summary: The gyratory crusher has become an indispensable equipment in industries such as environmental protection, mining, metallurgy, and building materials due to its efficient crushing capacity and wide application fields. With the continuous advancement and innovation of technology, rotary crushers will be applied in more fields, providing strong support for the development of the industry.

Save Time! Get A Detailed Quotation Quickly.