Disc Screen, as an efficient sorting device, can be applied to various types of waste treatment and separation work. It can efficiently separate materials of different sizes and shapes through its unique structural characteristics and working principle, achieving resource recycling and environmental protection. Disc shaped screens can be used to screen small volume impurities, dust powders, combustible and non combustible waste. Therefore, disc shaped screens are widely used in the waste recycling industry to sort mixed industrial waste and waste from other recycling plants except for sanitary landfills.

A. Application of Disc Screen in Garbage Sorting:

1.In the treatment of stale garbage, Disc Screens can separate organic matter from other impurities, making it easier for further processing and utilization. This is of great significance for reducing the cost of garbage disposal and minimizing the impact on the environment. In addition, Disc Screens are widely used in mixed waste treatment. Through the separation effect of Disc Screens, different types of garbage can be effectively separated for corresponding treatment and recycling. This helps to reduce the volume and weight of garbage, lower the cost of garbage disposal, and achieve resource recycling.

In the treatment of household waste, Disc Screens can separate combustible and non combustible materials from the waste, facilitating subsequent processing and recycling. At the same time, it can also separate organic matter and small combustibles from other non combustibles such as sand and glass for corresponding processing and treatment. This is of great significance for reducing the cost of garbage disposal and minimizing the impact on the environment.

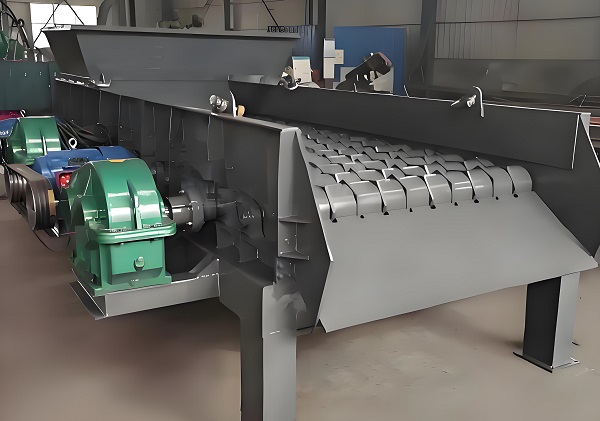

2. Disc sorting machine is used to sort inert garbage and small volume garbage. The disc-shaped screen of the disc sorting machine will rotate, driving the vibration of the garbage on the screen. There is a spacing between the disc-shaped screens to achieve sorting based on the size and weight of the garbage. According to different widths, 15 to 20 sieve plates can be installed on one bearing. Install different numbers of bearings according to the required screening processing capacity. The motor drives the bearings to rotate synchronously. Other shapes of sieve plates are easily clogged with wet garbage, while disc-shaped sieve plates do not have clogged sieve holes due to continuous rotation.

3.The application of Disc Screens will bring more efficient, energy-saving, and environmentally friendly solutions for garbage disposal. As a powerful tool for modern construction waste treatment, the disc-shaped sieve has completely overturned the limitations of traditional screening equipment with its high efficiency, non clogging, and high precision. It not only doubles the processing and production efficiency of construction waste, but also makes important contributions to urban environmental protection and resource reuse. Choosing a disc-shaped sieve means choosing an efficient and environmentally friendly future.

4. In urban household waste treatment, Disc Screens are commonly used in the primary screening stage to separate large waste (such as furniture, large appliances, etc.) from small waste (such as food residues, waste paper, etc.). In the treatment of construction waste, it can be used to separate large particles such as concrete blocks and brick debris from small dust, preparing for subsequent crushing, grinding, and other processes.

B. The advantages of Disc Screen

1. Sturdy structure and good quality:

The Disc Screen adopts wear-resistant chain drive and strong bearings with centralized lubrication, making the overall structure of the equipment sturdy and durable.

The overall module design is easy to maintain and adjust the structure, ensuring that the equipment can operate stably for a long time.

2. High screening efficiency:

The Disc Screen uses a unique rotating design to continuously flip the material on the screen surface, effectively avoiding the problem of material blockage, especially when dealing with wet and sticky materials, it can still maintain efficient operation.

Compared to traditional screening equipment, Disc Screens have significantly increased processing capacity, higher screening efficiency, and can quickly classify and process solid waste such as construction waste.

3. High screening accuracy:

Disc Screen can accurately classify materials of different particle sizes, making recycled aggregates cleaner and more uniform.

Adjusting the gap between the discs can effectively separate materials with significant differences in size, meeting different sorting needs.

4. Stable operation and energy-saving:

The Disc Screen adopts a variable frequency infinitely variable speed control method, which can adjust the processing capacity according to needs and reduce energy consumption.

The hood sealing design effectively prevents dust and noise, providing a safe and clean working environment.

5. Energy conservation and environmental protection

Compared to traditional screening equipment, Disc Screens have significant advantages in energy consumption, which can reduce energy consumption while ensuring high efficiency. At the same time, its enclosed structural design can effectively reduce dust flying and alleviate the impact on the environment.

6. Easy to maintain

The design of the Disc Screen takes into account the convenience of daily maintenance. For example, screen replacement is simple and fast, and can be completed without disassembling the entire machine, reducing maintenance costs and time.

7. Wide application range:

Disc Screen is suitable for sorting various types of solid waste such as household waste, construction and decoration waste, stale waste, kitchen waste, etc.

C. The function of Disc Screen

Disc Screen (also known as Disc Screening machine or butterfly vibrating screen) has a wide range of applications in the field of garbage sorting due to its unique structural design and efficient screening performance. This screening equipment is particularly suitable for processing complex materials containing multiple components such as urban household waste and construction waste. The following are the main functions of Disc Screens in sorting garbage:

1. Material classification

Disc Screens can effectively classify garbage according to size. By adjusting the aperture size of the sieve, precise separation of materials with different particle sizes can be achieved, which is crucial for subsequent resource recovery and processing. For example, separating recyclable materials such as plastic and paper from other waste for further processing and utilization.

2. Remove impurities

In the process of garbage disposal, it is often necessary to remove some unwanted or harmful impurities. Disc Screen can effectively remove impurities such as stones, metal fragments, etc. through appropriate sieve hole design, thereby improving the purity and quality of the final product.

3. Improve processing efficiency

The Disc Screen works by vibration, which can quickly and evenly distribute materials on the screen surface, greatly improving the screening efficiency. In addition, its special butterfly shaped structure design facilitates material flow, reduces the possibility of blockage, and ensures continuous and stable operation.

4. Resource utilization of garbage:

Disc Screens can comprehensively treat various types of solid waste resources, separate useful substances, and provide high-quality raw materials for subsequent production and application.

The construction waste processed by Disc Screening can be converted into recycled aggregates for the production of new environmentally friendly materials such as recycled concrete and recycled bricks, achieving the recycling of resources.

5. Significant environmental benefits:

The Disc Screen reduces the pollution of garbage to the environment and promotes the development of green building materials through efficient screening and resource reuse.

In line with the concept of sustainable development, it helps to build an environmentally friendly society.

It has broad application prospects in the fields of urban solid waste treatment, industrial waste treatment, etc. Disc Screens play an important role in garbage sorting with their unique advantages, not only improving screening efficiency and accuracy, but also maximizing the resource utilization and environmental benefits of garbage. With the continuous advancement of technology and the expansion of the market, the application prospects of Disc Screens in the field of waste treatment will be even broader.

In summary, Disc Screens have played an important role in the field of garbage sorting due to their efficient screening ability and energy-saving and environmentally friendly characteristics, and are one of the indispensable key equipment in modern garbage treatment systems.

Save Time! Get A Detailed Quotation Quickly.