The treatment of kitchen waste is an important part of urban environmental management and resource recycling. By means of classified collection and biotechnology transformation, the pollution of kitchen waste to the environment can be effectively reduced, while achieving the reuse of resources.

A. The role of kitchen waste treatment is mainly reflected in the following aspects:

1. Reduce environmental pollution: Kitchen waste is prone to decay and odor. If discarded without proper treatment, it can breed bacteria, attract pests, and cause water and soil pollution. Properly handling kitchen waste can reduce these negative impacts.

2. Resource recycling: Kitchen waste is rich in organic matter and can be converted into fertilizers, feed, or bioenergy (such as biogas and biodiesel) through biotechnology treatment, achieving the reuse of resources.

3. Promoting low-carbon development: Compared to traditional treatment methods such as landfill and incineration, the recycling and utilization of kitchen waste can significantly reduce greenhouse gas emissions and help achieve carbon neutrality goals.

In summary, the treatment of kitchen waste is of great significance for environmental protection and resource recycling.

B. Resource based (composting) kitchen waste treatment equipment

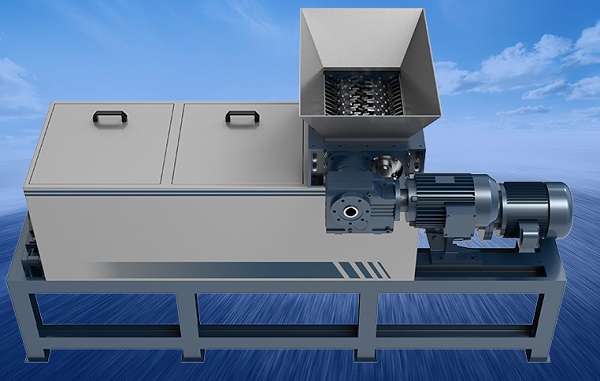

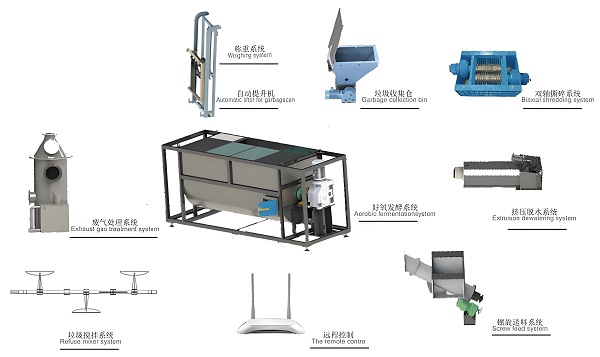

The organic fertilizer treatment equipment for kitchen waste uses organic waste such as kitchen, kitchen waste, and tail vegetables as raw materials. Through technologies such as crushing, dehydration, oil extraction, and fermentation, it can achieve a reduction of over 90% in waste. This device includes functions such as automatic weighing and lifting, secondary sorting, pressing and dehydration, oil-water separation, spiral lifting, aerobic fermentation, oxygen supply, deodorization, etc. After treatment, organic fertilizer can be used for planting plants, wastewater can be discharged after subsequent treatment to meet standards, and waste oil can be recycled as biomass fuel raw materials.

1. Process flow of organic fertilizer treatment for kitchen waste

a. The on duty personnel push the kitchen waste bin to the equipment location;

b. A lift with "weighing and lifting" function automatically pours kitchen waste into the equipment;

c. After being "crushed and dehydrated", kitchen waste is transported to the fermentation bin through an automatic conveying channel as solid residue;

d. After 8-24 hours of fermentation treatment, the solid residue is converted into organic fertilizer and discharged from the discharge outlet;

e. The gas generated during the fermentation process is discharged in compliance with standards after passing through a deodorization system;

d. The oil and fat separated from oil-water should be regularly recycled by qualified units.

2. Preprocessing system operation steps

a. The on duty personnel will hang the standard garbage bin filled with organic waste on the "elevator", and the bin cover will automatically open;

b. The "hoist" pours the material into the shredder (the size of the shredded material is 3-20mm);

c. The shredded material undergoes solid-liquid separation through a back pressure press;

d. After solid-liquid separation, the material residue enters the "fermentation system" through the "conveying system".

3. Fermentation system for kitchen waste

a. After pre-treatment, the residue is sent to the fermentation system for ultra-high temperature aerobic fermentation reaction;

b. Enter the subsequent fermentation chamber for secondary fermentation in sequence, and the system ensures that microorganisms grow and reproduce rapidly at the most suitable material temperature of around 80 degrees Celsius;

c. After 24 hours of fermentation and maturation in the fermentation chamber, the organic fertilizer is automatically discharged in the form of granular powder.

d. The bio organic compost products produced by it meet industry standards, and the appearance (sensory): powder products should be loose and have no foul odor; Granular products should have no obvious mechanical impurities, uniform size, and no spoilage odor.

4. Fermentation deodorization system for kitchen waste, operation steps of deodorization system:

a. Odorous gases are input into the deodorization system through exhaust equipment;

b. Efficiently reducing dust in gases containing fine particles through circulating water;

c. Decompose odorous gases through the high-energy UV ultraviolet beam of the "Atomic Infinite Lamp";

d. Degradation and conversion of odorous gases into low molecular weight compounds, water, and carbon dioxide;

e. Then, it is discharged outdoors through the exhaust duct to meet the standard;

f. The odor emission around the site shall comply with the Class II standard of odor pollutant emission standards.

C. Kitchen waste treatment technology

Kitchen waste in household waste is one of the main types of urban waste. Currently, there are various methods for treating food waste, including anaerobic fermentation, aerobic composting, feed production, incineration, and landfill. Among them, anaerobic fermentation and aerobic composting are the mainstream treatment processes, and pre-treatment requires bag breaking and crushing processes. Therefore, only the above two processes will be introduced and analyzed.

1. Anaerobic fermentation process for meal waste

The anaerobic fermentation process is the use of microorganisms to decompose organic matter in a specific anaerobic environment, where some carbohydrates are converted into methane and carbon dioxide. There are various classifications for anaerobic fermentation technology. According to the concentration of organic matter in kitchen waste, it can be divided into dry anaerobic fermentation and wet anaerobic fermentation; According to the reaction order, it can be divided into single-phase anaerobic fermentation and two-phase anaerobic fermentation; According to the continuity of operation, it can be divided into continuous anaerobic fermentation and intermittent anaerobic fermentation; According to temperature, it can also be divided into room temperature anaerobic fermentation, medium temperature anaerobic fermentation (30-40 ℃), and high temperature anaerobic fermentation (50-60 ℃). According to the high moisture content of kitchen waste in China, wet, single, continuous, and medium temperature anaerobic fermentation is currently widely used in engineering. Meal waste first needs to be treated by breaking the bags to preliminarily crush the bagged meal waste and large debris. Zhongcheng Machinery has designed and developed a professional meal waste crusher with a production capacity of 20-30t/h to meet the requirements of crushing and processing meal waste. Its features include: a large feeding port suitable for grabbing buckets and conveyors, a long knife hook without the need for a pressing mechanism, a high spindle speed to avoid sticking to the knife, simple maintenance without the need for disassembly and assembly of cutting tools, and multiple crushing mechanisms such as shearing, chopping, and hammering that can adapt to materials of various properties.

2. Aerobic composting process for meal waste

The mainstream treatment process for meal waste is aerobic composting. Aerobic composting is carried out under aerobic conditions, relying on the action of aerobic microorganisms (mainly aerobic bacteria). Aerobic composting, as one of the effective ways for the harmless treatment of urban food waste resources, produces compost products rich in humus and nutrients such as nitrogen, phosphorus, and potassium. It is not only a soil amendment but also a high-quality fertilizer. The pretreatment process of aerobic composting for meal waste is similar to that of anaerobic fermentation. After receiving meal waste, it is first crushed and sorted to remove impurities that are not suitable for composting, and then compressed and dehydrated to adjust the moisture content of the waste; Then add the necessary auxiliary additives for composting in the fabric box for aerobic composting treatment. The coarse product after composting can be sold after secondary screening and packaging; The sewage generated during the transportation and compression dehydration processes enters the water treatment system for centralized treatment and is discharged in compliance with standards. Its advantages are: simple process, suitable for waste treatment with high content of perishable organic matter, and the product can be used as animal feed or fertilizer for soil improvement. The disadvantage is that due to the complexity of kitchen waste in China, it cannot effectively solve the pollution of harmful organic compounds such as oil, salt, and heavy metals, and the harmless treatment is not thorough; The handling process is not closed, which can easily cause secondary pollution.

There are no new projects for the feed processing technology of meal waste due to the difficulty in solving protein homology problems. And incineration or landfill treatment, after garbage classification, will gradually be replaced by resource utilization processes such as anaerobic fermentation.

The treatment of kitchen waste can reduce the environmental pressure caused by landfill and incineration, decrease greenhouse gas emissions, and reduce soil and water pollution. Kitchen waste is rich in organic matter, which can be scientifically processed and converted into useful resources such as fertilizers and feed, contributing to sustainable agricultural development.

In the future, with the advancement of technology and the promotion of policies, the treatment of kitchen waste will become more efficient and environmentally friendly, achieving a win-win situation of economic, social, and environmental benefits. Therefore, strengthening the treatment of kitchen waste and promoting scientific treatment methods are of great significance for improving urban management level and promoting ecological civilization construction.

Save Time! Get A Detailed Quotation Quickly.