Trommel Screen is a kind of equipment that separates solid materials by rotating drum screen and classifies according to particle size of materials. It is mainly composed of steel plate, motor, reducer, frame, etc.with high efficiency, not easy to be blocked, stable operation and low noise. Drum screen is widely used in environmental protection, mining, building materials, coal, chemical industry and other industries, used for waste treatment, ore classification, sand screening, coal washing and other operations, can effectively improve the quality of materials and production efficiency, meet the production requirements.

【Device Type】:Sorting Equipment

【Handling Materials】:Rubbish, coal, sand, sand, food, soil, etc..

【Equipment capacity】:10-1000T/H

【Equipment power】:10-150W/H

【Scope of application】:Domestic garbage, construction/decoration garbage, commercial/industrial garbage, etc.

The trommel screen, also known as the Trommel Screening machine, is a grading processing equipment widely used in many industries. It mainly uses a rotating cylindrical screen to grade the material according to the particle size to improve the quality and production efficiency of the material.

The structure of the Trommel Screen is mainly composed of a hexagonal drum, a frame, a funnel, a reducer, a motor and other parts. The drum of the Trommel Screen is generally divided into several sections, depending on the specific situation. The aperture of the screen holes on each section is the same, and the screen holes are arranged from small to large. After the material enters the drum, on the one hand, it is screened as the drum rotates, and on the other hand, the material with large particle size flows forward along the slope of the drum and is gradually screened out through the screens of different meshes. During the screening process, the material is subjected to the force of rotation in the drum, and materials of different particle sizes will pass through the different apertures of the screen to achieve material screening and separation.

The Trommel Screen has many advantages. First of all, it runs slowly and evenly, with little impact vibration, stable operation, simple installation, and sometimes even does not require a special foundation. It can be placed directly on a flat ground or floor and under a silo. Secondly, the Trommel Screen is equipped with a comb-type cleaning mechanism, which can achieve the effect of uninterrupted cleaning of the screen body through relative movement, so that the screening cylinder is always clean, non-sticky, non-blocked, and does not affect the screening effect. In addition, the screen of the Trommel Screen adopts a replaceable sheet connection method, which is convenient for replacement or replacement of screens of different sizes after wear.

Trommel Screens are widely used in many industries such as environmental protection, mining, building materials, coal, highways, chemicals, refractory materials, sand field stones, etc. In the coal industry, Trommel Screens can be used to remove impurities such as gangue and wood blocks in coal to improve the purity and calorific value of coal. In the ore industry, Trommel Screens can be used to screen and grade ore to provide qualified raw materials for subsequent mineral processing and smelting. In addition, trommel tcreens can also be used for sorting urban domestic waste and sorting scrap metals.

It can be seen that the trommel screen is an efficient and reliable grading and processing equipment with broad application prospects.

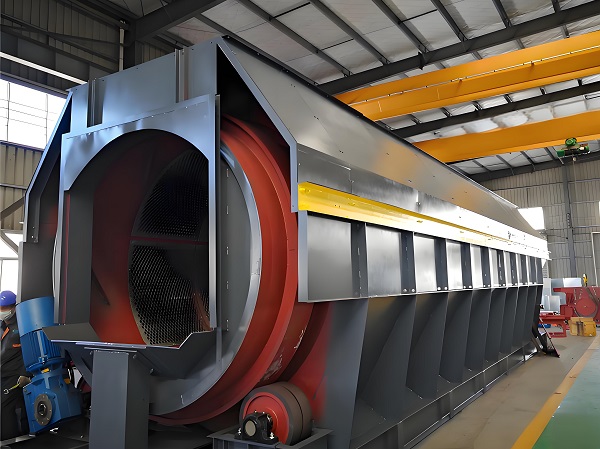

Zhongcheng Machinery's trommel screen

The working principle of the drum screen is as follows:

1. The basic structure and composition of the drum screen

The drum screen is mainly composed of the following key parts:

a. Drum device: This is the core component of the screening. It is composed of a screen composed of several circular flat steels. The whole is inclined to the ground plane. The outside is usually sealed by a sealed isolation cover to prevent environmental pollution.

b. Motor and reducer: The motor is connected to the reducer through a coupling to provide power for the drum screen, and the reducer adjusts the drum device to rotate at a certain speed.

c. Frame: Used to support the structure of the entire drum screen to ensure its stability.

d. Inlet and outlet: The material enters the drum device through the inlet, and the screened material is discharged from the outlet.

e. Comb-type cleaning mechanism: used to clean the screen during the screening process to prevent blockage.

2. Working principle and process of drum screen

a. Start and rotation: When the motor starts, the power is transmitted to the reducer through the coupling, and the reducer drives the drum device to rotate around its axis. The inclination and rotation of the drum device cause the material on the screen surface to flip and roll.

b. Material screening: After the material enters the drum device from the feed port, the material rolls in the drum under the centrifugal force generated by the rotation of the drum, and moves toward the discharge port as the drum rotates. During the rolling process, the material will be gradually separated and screened due to the different grading sizes of the screen. Fine materials will leak out of the screen, while coarse materials will continue to flow forward along the inclination of the drum.

c. Screen cleaning: In order to prevent the screen from being blocked, the drum screen is usually equipped with a comb-type cleaning mechanism or other cleaning devices. These cleaning devices will produce relative movement with the screening drum, thereby achieving the effect of uninterrupted cleaning of the screen body. This ensures that the screening drum remains clean throughout the entire working process, without sticking, blocking, and affecting the screening efficiency.

Working principle diagram of trommel screen

As an efficient screening equipment, trommel screen plays a vital role in many industries. Its wide range of applications, high screening efficiency and strong adaptability make trommel screen an indispensable screening tool in many industries. The following is a detailed introduction to the application of trommel screen:

1. Garbage disposal: In the field of urban domestic waste disposal, trommel screen also plays an important role. Through the screening effect of trommel screen, useful substances such as metals, plastics, paper products, etc. can be effectively separated to achieve garbage reduction, resource utilization and harmless treatment. At the same time, trommel screen can also be used for the treatment and utilization of organic waste such as kitchen waste and garden waste, contributing to the improvement of urban environment and sustainable development.

2. Coal industry: In the coal industry, trommel screen is widely used for coal screening and impurity removal. Through the screening effect of trommel screen, impurities such as gangue and wood blocks in coal can be removed to improve the purity and calorific value of coal. At the same time, trommel screen can also grade coal by particle size to provide qualified raw materials for subsequent coal processing and utilization.

3. Ore industry: In the ore industry, trommel screens are used to screen and grade ore. In the process of ore crushing and grinding, trommel screens can effectively separate ore according to particle size, providing qualified raw materials for subsequent beneficiation and smelting. In addition, trommel screens can also be used in ore dehydration, desludging and other process to improve the processing efficiency of ore.

4. Building materials industry: In the building materials industry, trommel screens are widely used in the production process of building materials such as cement and sandstone. Through the screening effect of the trommel screen, the particle size of raw materials can be accurately controlled to improve the quality and performance of building materials. At the same time, the trommel screen can also be used for impurity removal and grading of building materials, providing high-quality raw materials for subsequent processing and utilization.

5. Chemical industry: In the chemical industry, trommel screens are used to screen and control the particle size of chemical raw materials. Through the screening effect of the trommel screen, the particle size of chemical raw materials can be ensured to be uniform, and the efficiency of chemical reactions and product quality can be improved. In addition, trommel screens can also be used for the treatment and recycling of chemical waste to achieve the recycling of resources.

6. Grain processing: In the grain processing industry, trommel screens are used for grain cleaning and grading. Through the screening effect of the trommel screen, impurities and broken grains in the grain can be removed, improving the quality and safety of the grain. At the same time, the trommel screen can also be used in grain drying and shelling processes to improve grain processing efficiency and added value.

7. Metallurgical industry: In the metallurgical industry, trommel screens are used for screening and pretreatment of furnace charges. Through the screening effect of the trommel screen, the consistency and quality of materials in the metallurgical process can be ensured, and the quality and production efficiency of metallurgical products can be improved.

Zhongcheng Machinery's Trommel screen for garbage screening

Author's note: As an efficient screening equipment, trommel screen has been widely used in many industries. Its characteristics and advantages are simple structure, high screening efficiency, wide application range, easy maintenance and high degree of automation. The following is a detailed introduction to the characteristics and advantages of trommel screen:

A. Characteristics of trommel screen

Zhongcheng Machinery's trommel screen

1. Simple structure:

a. The trommel screen is mainly composed of screen drum, drive device, support device and control system, and the structure is relatively simple and clear.

b. The screen drum is usually woven with high-strength steel or wear-resistant steel wire, with good wear resistance and corrosion resistance, ensuring the long-term stable operation of the equipment.

2. High screening efficiency:

a. The screen surface of the trommel screen is large, and a large amount of material can be processed at the same time, thereby improving the screening efficiency.

b. The screen hole is not easy to be blocked, the material rolls back and forth in the drum, and the material in the screen hole is ejected, ensuring the continuity and efficiency of screening.

c. The screening efficiency is usually around 80%, which is much higher than traditional screening equipment.

3. Wide range of applications:

a. The trommel screen is suitable for screening of various materials, such as chemical, building materials, metallurgy, coal, grain processing and other industries.

b. It can handle wet materials, sticky materials and materials of different particle sizes, and has a wide range of adaptability.

4. Easy to maintain:

a. The structure of the trommel screen is relatively simple, easy to disassemble and clean.

b. For some materials that are easy to clog, they can be easily handled by simple cleaning operations.

c. The maintenance workload is small, which reduces the maintenance cost.

5. High degree of automation:

a. With the continuous advancement of automation technology, the trommel screen has also achieved intelligent operation.

b. Equipped with automatic feeding, automatic cleaning, automatic slag discharge and other devices, it can achieve fully automatic operation and reduce labor costs.

B. Advantages of trommel screen

Zhongcheng Machinery's trommel screen

1. Strong customization:

a. The trommel screen can customize various specifications and models of screening equipment according to the actual production needs of users.

b. A variety of different vibration modes and screen accuracy can be selected to meet the screening requirements of different materials.

2. Smooth operation:

a. The trommel screen has low noise during operation and meets national standards.

b. Smooth operation reduces vibration and wear of the equipment and prolongs its service life.

3. Energy saving and environmental protection:

a. The trommel screen has relatively less dust during the production process, which is beneficial to environmental protection.

b. The use of advanced lubrication system reduces energy consumption and reduces operating costs.

4. Small footprint:

a. Although the trommel screen requires a certain amount of installation space, it occupies a smaller area than other screening equipment.

b. This makes the trommel screen well applied even when the site is limited.

5. High screening accuracy:

a. The trommel screen is equipped with multiple layers of screens, and different screen accuracies can be selected according to different screening requirements.

b. High-precision screening can be achieved by adjusting parameters such as the aperture of the screen and the inclination angle of the drum.

PS: The trommel screen has been widely used in many industries for its simple structure, high screening efficiency, wide range of application, easy maintenance and high degree of automation. At the same time, its advantages such as strong customization, smooth operation, energy saving and environmental protection, small footprint and high screening accuracy also make the trommel screen highly competitive in the market. In the future, with the continuous advancement of technology and the continuous development of the market, the application prospects of trommel screens will be broader.

Author's note: Purchasing a trommel screen is a comprehensive decision-making process involving multiple factors. In order to ensure that you choose a trommel screen that suits your needs, the following is a detailed purchase guide:

1. Clarify your screening needs

Clarify your own screening needs, including material characteristics, processing capacity, screening accuracy, etc. Material characteristics such as humidity, viscosity, particle size distribution and corrosiveness will directly affect the selection of the trommel screen. The processing capacity determines the scale of the trommel screen, while the screening accuracy requires the trommel screen to have a corresponding screen aperture and screening efficiency.

Trommel Screen

2. Examine equipment performance

a. Drum diameter and length: The diameter and length of the drum are important factors affecting screening capacity. Large diameter and long drums usually improve screening efficiency and processing capacity, but also increase equipment cost and floor space. Therefore, it is necessary to select the appropriate drum size according to actual needs.

b. Screen design: The aperture size, type (such as woven screen, punched screen) and number of layers of the screen will directly affect the screening effect. It is necessary to select a suitable screen design according to material characteristics and screening requirements.

c. Drive mode: The drive modes of trommel screen include motor drive, hydraulic drive, etc. Motor drive is usually low-cost and simple to maintain; hydraulic drive has higher flexibility and stability. It is necessary to choose the appropriate drive mode according to actual needs and budget.

d. Self-cleaning ability: For materials with high humidity or strong viscosity, the self-cleaning ability of trommel screen is particularly important. trommel screens with clearing devices or special screen structures can better prevent clogging of the screen holes.

3. Pay attention to materials and durability

The material of the trommel screen directly affects its durability and service life. High-quality high-strength steel plates, wear-resistant alloy steels or stainless steel materials can resist the wear and corrosion of materials and extend the service life of the equipment. At the same time, good welding technology and assembly accuracy are also important factors to ensure the durability of the equipment.

4. Consider installation and maintenance

a. Installation method: The installation methods of trommel screen are fixed and mobile. Fixed trommel screens are suitable for occasions with fixed sites and large processing volumes; mobile trommel screens are easy to flexibly adjust the screening position and are suitable for occasions with limited sites or frequent movement.

b. Maintenance convenience: Choose a trommel screen with a simple structure, easy to disassemble and install, which is convenient for daily maintenance and overhaul. At the same time, find out whether the manufacturer provides perfect after-sales service and technical support so that it can be solved in time when the equipment fails.

Trommel Screen

5. Evaluate the cost performance

On the premise of meeting the screening needs and quality requirements, compare the prices of different equipment and choose a trommel screen with high cost performance. But don't just pursue low prices and ignore the quality and performance of the equipment. You can understand the reputation and product quality of the manufacturer by checking the qualification certificate, customer evaluation, industry reputation, etc.

6. Field investigation and trial operation

If conditions permit, it is recommended to visit the manufacturer's production base on site to check the actual operation of the equipment. Through trial operation, you can more intuitively evaluate the performance, stability and screening effect of the equipment, so as to make a more informed purchase decision.

PS: The purchase of trommel screens requires comprehensive consideration of screening needs, equipment performance, material and durability, installation and maintenance, cost performance, field investigation and trial operation, etc. Only through comprehensive evaluation and comparison can you choose a trommel screen equipment that suits your needs.

| Model | Specification | Diameter | Rotating speed (rpm) | Power (kW) |

| ZCTS1230 | Φ1.2×3 | Φ1200 | 12-17 | 4-5.5 |

| ZCTS1530 | Φ1.5×3 | Φ1500 | 12-17 | 5.5-11 |

| ZCTS1550 | Φ1.5×5 | Φ1500 | 12-17 | 11-15 |

| ZCTS1850 | Φ1.8×5 | Φ1800 | 10-15 | 11-18.5 |

| ZCTS2060 | Φ2.0×6 | Φ2000 | 10-15 | 18.5-22 |

| ZCTS2580 | Φ2.5×8 | Φ2500 | 10-15 | 22-38 |

Note: Technical specifications may change without notice due to ongoing technological advancements.

2025-02-11

2025-02-11

2025-02-08

2025-02-08

2024-12-28

2024-12-28

2024-12-28

2024-12-28

2024-12-10

2024-12-10

2024-12-07

2024-12-07

2024-12-04

2024-12-04

2024-12-04

2024-12-04

2024-12-04

2024-12-04

2024-12-03

2024-12-03Save Time! Get A Detailed Quotation Quickly.