The drum screen is a commonly used screening equipment, which is widely used in screening operations of various materials. In order to ensure the normal operation of the drum screen and extend its service life, daily maintenance and troubleshooting are required. The following is a detailed introduction to the daily maintenance and troubleshooting of the drum screen:

A. Daily maintenance of the drum screen

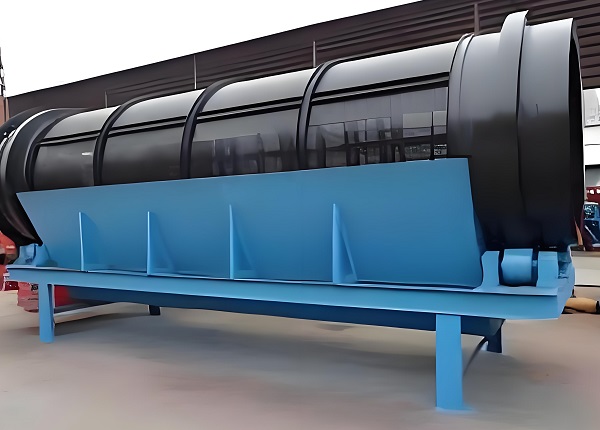

Drum Screen(Trommel Screen)

1. Lubrication work: Do a good job of lubricating the drum screen, ensure that all parts are refueled in time, and prevent wear and failure caused by poor lubrication.

2. Electrical inspection: Observe the electrical equipment of the drum screen every day, including motors, cables, junction boxes, etc., to ensure that they work normally and without abnormal conditions. At the same time, the junction boxes, motors, etc. should be regularly maintained and maintained to prevent electrical failures.

3. Bolt inspection: Regularly check whether the bolts of various parts of the drum screen are loose. If they are loose, they should be tightened in time to prevent equipment noise and failures caused by loose bolts.

Drum Screen(Trommel Screen)

4. Filter maintenance: Daily maintenance of the drum filter should be carried out after shutdown. Check whether the filter is damaged, blocked or deformed. If there is any abnormality, it should be replaced or cleaned in time.

5. Bearing temperature monitoring: The bearing temperature of the drum screen should not be too low or too high. The bearing temperature should be checked regularly and an appropriate amount of lubricant should be added to ensure the normal operation of the bearing.

6. Inspection after shutdown: After each shutdown, the screen, bearing, gearbox and other parts of the drum screen should be checked for abnormal wear or damage. If any, they should be handled in time.

Drum Screen(Trommel Screen)

B. Troubleshooting of drum screen

1. Noise problem: When the drum screen makes noise, it may be caused by loose bolts or wear of rollers. At this time, the bolts should be re-tightened or the rollers should be replaced, and an appropriate amount of lubricant should be added to reduce noise.

2. Wrong rotation direction: If the drum screen rotates in the wrong direction, it may be caused by the wrong connection of the motor power cable. At this time, the power cable in the junction box should be replaced to ensure the correct rotation direction of the drum screen.

3. Slow motor start-up: Slow motor start-up may be caused by the conveying volume exceeding the allowable value, the motor overload or insufficient torque when the motor starts. At this time, the conveying volume should be readjusted, the load should be reduced, and the torque and wiring of the motor should be checked for normality.

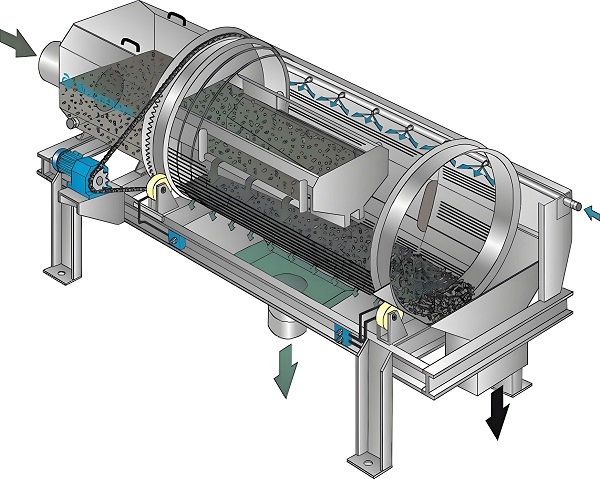

Schematic of Drum Screen(Trommel Screen)

4. Gearbox heating: Gearbox heating may be caused by insufficient ventilation or insufficient lubricant in the box. At this time, the heat dissipation effect of the vent should be checked and adjusted, and an appropriate amount of lubricant should be added to reduce the temperature of the gearbox.

5. Motor heating: Motor heating may be caused by too short cooling time, too high working environment temperature, motor overload, loose connection wires or wrong wiring. At this time, the heat sink of the motor should be cleaned, the fan impeller should be checked to see if it is working properly, the load should be reduced, the connection should be tightened, and the wiring should be reconnected to ensure the normal operation of the motor.

6. Screen hole blockage: Screen hole blockage may be caused by too large material or broken screen. At this time, the blocked garbage should be cleaned in time, and the screen should be checked for damage or deformation, and if so, it should be replaced in time.

7. Bearing heating: Bearing heating may be caused by insufficient lubricant or bearing wear. At this time, check whether the bearing and lubricant are distributed in place, and add an appropriate amount of lubricant. If the bearing is severely worn, a new bearing should be replaced in time.

Technical parameter table of Drum Screen(Trommel Screen):

Model | Capacity | Power | Screen diamater | Screen Length | Input size | Discharge size | Dimension (L×W×H) |

(t/h) | (kw) | (mm) | (mm) | (mm) | (mm) | (mm) | |

ZCTM1020 | 20-30 | 4.0 | 1000 | 2000 | 0-100 | ≤300 | 3390x1400x2140 |

ZCTM1225 | 30-50 | 5.5 | 1200 | 2500 | 0-100 | ≤300 | 4146x1600x2680 |

ZCTM1545 | 50-120 | 11 | 1500 | 4500 | 0-100 | ≤400 | 8160×2300×2500 |

ZCTM1548 | 80-150 | 15 | 1500 | 4800 | 0-100 | ≤400 | 8160×2300×2500 |

ZCTM1848 | 100-200 | 15 | 1800 | 4800 | 0-100 | ≤400 | 8460×2300×2700 |

ZCTM2060 | 200-400 | 30 | 2200 | 6500 | 0-100 | ≤400 | 9680×2300x3420 |

PS: Daily maintenance and troubleshooting of drum screens are essential to ensure their normal operation and extend their service life. Through regular maintenance and timely troubleshooting, the working efficiency and reliability of the drum screen can be effectively improved.

Save Time! Get A Detailed Quotation Quickly.