Looking for a reliable and efficient way to recycle tin cans, paint buckets, or other tin waste? A tin shredder is the perfect solution. As a trusted twin-shaft shredder manufacturer, we provide heavy-duty shredders that help you process tin waste, reduce its volume, and prepare it for further recycling or smelting.

A tin shredder is a type of industrial shredding machine specially designed to reduce the size of tin materials such as tin cans, paint buckets, oil filters, and other light metal scrap. Unlike a simple crusher or can press, a tin shredder uses rotating blades to tear, shear, and cut the material into smaller, uniform pieces, making it easier to store, transport, and recycle.

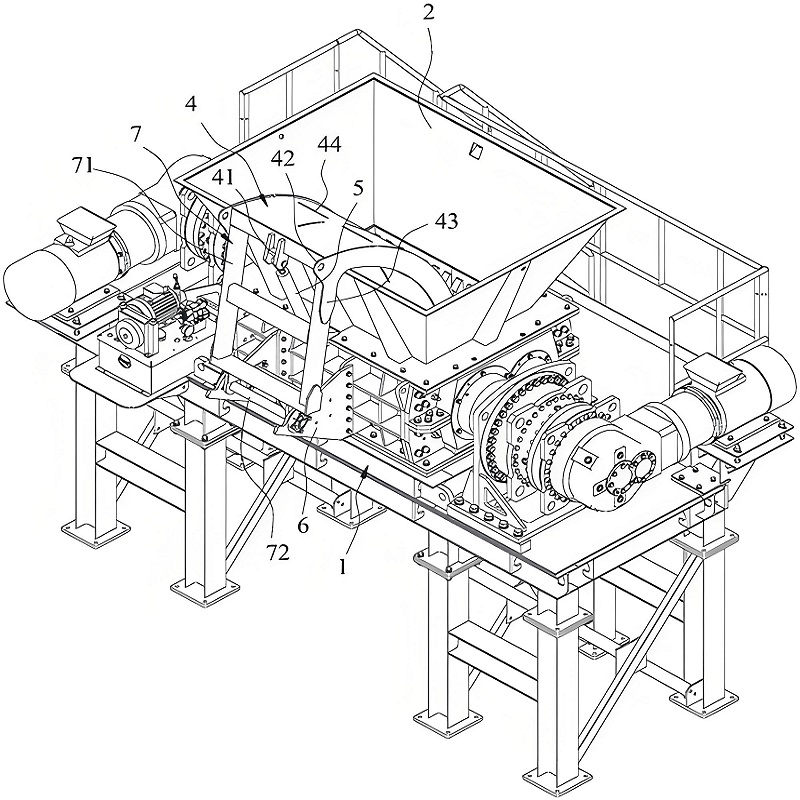

Most modern tin shredders are twin-shaft shredders (also called dual-shaft shredders). This design features two counter-rotating shafts equipped with cutting blades. The two shafts pull the tin material in and cut it simultaneously, which makes the process smooth, efficient, and suitable for continuous operation.

Key features of a tin shredder include:

Heavy-Duty Construction: Built with thick steel plates and a strong gearbox to handle metal materials.

Low-Speed, High-Torque Motors: Provide powerful shearing force without generating excessive heat or noise.

Intermeshing Blades: The cutter discs have hooks or teeth that grab, rip, and shear the tin efficiently.

Customizable Output Size: The shredded piece size depends on the blade thickness, cutter diameter, and spacing between blades.

The primary purpose of a tin shredder is to:

Reduce Volume: Minimize storage space and lower transportation costs.

Prepare Material for Recycling: Small pieces are easier to melt, separate, or process in downstream recycling equipment.

Improve Efficiency: Shredding prevents bulky tin containers from blocking other machines in a recycling line.

Enhance Safety: Crushing sharp-edged metal manually is dangerous; shredders automate the process safely.

Because of these features, tin shredders are widely used in metal recycling plants, waste management facilities, paint and chemical industries, and scrap yards where tin waste is collected and processed.

1.Identify Your Material – Know what you are shredding: tin cans, paint buckets, oil filters, or mixed light metal scrap.

2.Capacity Requirements – Choose a shredder based on the hourly throughput you need (kg/h or t/h).

3.Decide how small you want the shredded pieces. Cutter thickness and tooth design affect final size.

4.Motor Power & Torque – Ensure the shredder has enough power to handle metal without jamming.

5.Durability & Blade Material – Look for wear-resistant alloy steel cutters with easy replacement options.

6.After-Sales Support – Choose a supplier that offers spare parts, installation guidance, and technical service.

The wear-resistant layer is added to the cutter shaft, and the toughness and strength ratio of the cutter are adjusted, so that the basic functions of the equipment can play a higher.

The power system, crushing system, hydraulic feeding system, rapid discharging system, intelligent protection system and maintenance system are integrated.

The new equipment has strong integration. Three upgrades have made all functions more compatible with the GI intelligent monitoring system of ZC.

This shredder incorporates the latest advancements in shredding technology, efficiency, and reliability.

A tin shredder (usually a twin-shaft shredder) operates on a low-speed, high-torque shearing and tearing principle. Instead of grinding or repeatedly cutting material, it relies on powerful torque to grab, pull, and tear tin scrap into smaller pieces.

Step-by-Step Process:

Feeding: Material (tin cans, paint buckets, oil filters, or thin sheet metal) is loaded into the hopper, either manually or via a conveyor.

Grabbing & Feeding: The counter-rotating shafts equipped with hook-shaped blades grab and pull the material into the cutting zone.

Shearing & Tearing: The intermeshing blades shear and tear the material apart in a single pass, reducing its size efficiently.

Discharge: Shredded tin pieces fall through the discharge opening, usually onto a conveyor belt or into a collection bin.

Reverse Function (Anti-Jam): If the machine detects a jam, the shafts automatically reverse to release the material and prevent damage.

Important Notes:

Output size is primarily determined by cutter thickness, number of teeth, cutter diameter, shaft speed, and the physical properties of the material.

For finer sizing, a secondary shredder or screening system (trommel screen, vibrating screen) is usually added downstream.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| ZCE312 | 1-2 | 30-120 | 3000×2000×3000 |

| ZCE315 | 3-5 | 3600×2000×3000 | |

| ZCE320 | 6-8 | 3800×2000×3000 | |

| ZCE330 | 8-10 | 5600×2200×3300 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.