Preface: In key areas such as industrial production and resource recycling, shredders play an indispensable role. They effectively support the production needs of different industries by crushing various materials. There are a wide variety of shredder products on the market, and the quality is also uneven, which makes many users confused when choosing. How can we accurately choose a shredder product that meets our needs? The following editor will analyze the key points of choosing a shredder from multiple key dimensions.

A. Accurately grasp the characteristics of materials

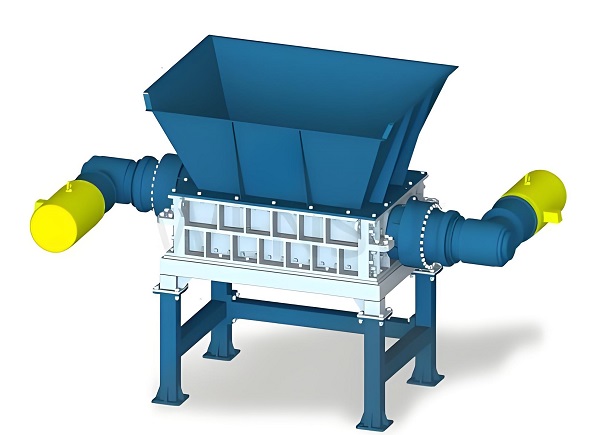

Shredder

1. Material types

Different types of materials have different physical and chemical properties, so the types of shredders that are suitable for them are also different. Take metal materials as an example, such as scrap auto parts, metal pipes, etc. These materials are quite hard and require shredders equipped with high-strength knives and sturdy body structures to effectively crush them; while for soft materials such as plastics and rubber, ordinary double-axis shredders can usually complete the shredding task excellently. If you are dealing with household waste with complex components, including plastics, metals, fabrics, paper and other materials, you need to choose a shredder that is versatile and can adapt to complex materials.

2. Material size

The original size of the material is directly related to the selection of the size of the shredder feed port. If the material size is too large and the shredder feed port is too small, the material must be pre-processed first, which will undoubtedly increase production costs and time costs; on the contrary, if the feed port is too large, it may lead to low shredding efficiency when dealing with smaller materials. Therefore, before selecting a shredder, be sure to accurately measure the maximum size of the material to ensure that the feed port of the selected equipment can smoothly accept the material.

3. Material hardness

Material hardness is an extremely critical characteristic. For materials with lower hardness such as paper and fiber, conventional shredders can easily cope with it; but when facing materials with higher hardness such as glass and stone, you must choose a shredder equipped with special tool materials (such as alloy steel, carbide, etc.) and a powerful power system. Knives made of different materials have different wear resistance, toughness and strength, and are suitable for materials of different hardness. Users need to choose the model reasonably according to the hardness of the material.

B. Clear production demand

Shredder

1. Production scale

The production scale of the enterprise directly determines the requirements for the processing capacity of the shredder. Large enterprises have a large production scale and high material processing requirements, so they need to choose a shredder with large processing capacity and high degree of automation. This type of equipment is usually equipped with multiple high-power motors, which can achieve continuous and stable operation and fully meet the needs of large-scale production; while small enterprises or workshops have a small production scale and relatively low material processing volume. They can choose a small and economical shredder, which can meet production needs without wasting equipment investment.

2. Expected output

Before choosing a shredder, you must clarify your expected output. According to the expected output, combined with the daily working hours, calculate the required shredder's processing capacity per hour. For example, if it is planned to process 10 tons of materials per day and the working time is 8 hours, then the processing capacity per hour must reach at least 1.25 tons. When selecting a model, you need to refer to the technical parameters of the equipment to ensure that its processing capacity can reach or even exceed the expected output. At the same time, you also need to fully consider the actual situation in the production process, such as the maintenance time of the equipment, the stability of the supply of materials, etc., and appropriately reserve a certain amount of production space to ensure the continuity of production.

C. Comprehensive consideration of equipment performance

1. Tool quality

As the core component of the shredder, the quality of the tool is directly related to the shredding effect and the service life of the equipment. High-quality tools should have good wear resistance, high strength and high toughness, and can remain sharp during long-term work, effectively reducing wear. When choosing a shredder, you must have a deep understanding of the material and manufacturing process of the tool. Generally speaking, tools made of advanced forging technology and high-quality alloy materials have better performance. In addition, you also need to pay attention to the repairability and convenience of replacement of the tool, which can effectively reduce the subsequent maintenance costs.

2. Motor power

The motor power determines the power of the shredder. If the power is too small, the material may not be effectively shredded, resulting in equipment jamming or even damage; if the power is too large, it will cause energy waste and increase equipment costs. The motor power should be reasonably selected according to the material characteristics and output requirements. Generally speaking, a motor with higher power is required to process materials with higher hardness and larger size; while the power can be relatively smaller for processing soft and smaller materials.

3. Degree of automation

With the rapid development of science and technology, the degree of automation of shredders is getting higher and higher. Shredders with high automation have functions such as automatic control, fault alarm, and remote monitoring, which can not only greatly improve production efficiency and reduce labor costs, but also facilitate equipment management and maintenance. If the budget permits, it is recommended to give priority to shredders with higher automation.

D. Pay close attention to equipment quality and brand

Shredder

1. Production process

High-quality shredders are constantly improving in production technology. From the overall structural design of the equipment to the processing and manufacturing of each component, they strictly follow relevant standards and specifications. When choosing a shredder, you can evaluate the quality of the equipment by visiting the manufacturer on site and carefully checking the manufacturing process details of the equipment. For example, observe whether the welding parts of the equipment are firm and flat, and whether the processing accuracy of the parts meets the requirements.

2. Brand reputation

Brand is an important guarantee for product quality and service. Choosing a shredder from a well-known brand often results in more reliable product quality and better after-sales service. Well-known brands usually have many years of production experience and have established mature systems in technology research and development, production management, and after-sales service. You can learn about the reputation and credibility of different brands through online searches, industry consultations, user reviews, and other channels, so as to choose reputable brand products.

E. Carefully evaluate after-sales service

1. Repair service

During long-term use, shredders will inevitably fail, and timely and effective repair services are essential. When choosing a shredder, you should understand the coverage and response time of the manufacturer's repair service network. Whether the manufacturer has an after-sales service point in the local area and whether the maintenance personnel can arrive at the site for repair in the shortest time are all factors that need to be considered. At the same time, you should also understand whether the manufacturer provides free maintenance training so that users can perform simple repairs on their own when the equipment has minor faults.

2. Accessories supply

The supply of accessories directly affects the normal operation and maintenance cost of the equipment. Make sure that the manufacturer of the selected shredder can supply various accessories in a timely manner and at a reasonable price. Some small manufacturers may have problems with the supply of accessories due to limited technology and production capacity, resulting in a long equipment maintenance cycle, which seriously affects the production progress.

PS: To choose the right shredder product, you need to comprehensively consider material characteristics, output requirements, equipment performance, quality brand, and after-sales service. Only by fully understanding these factors and making reasonable choices based on your actual situation can you buy a shredder product that truly suits your needs and provide strong support for the production and development of the company. During the purchase process, it is recommended that users consult industry experts and compare the products and services of different manufacturers to make wise decisions.

Save Time! Get A Detailed Quotation Quickly.