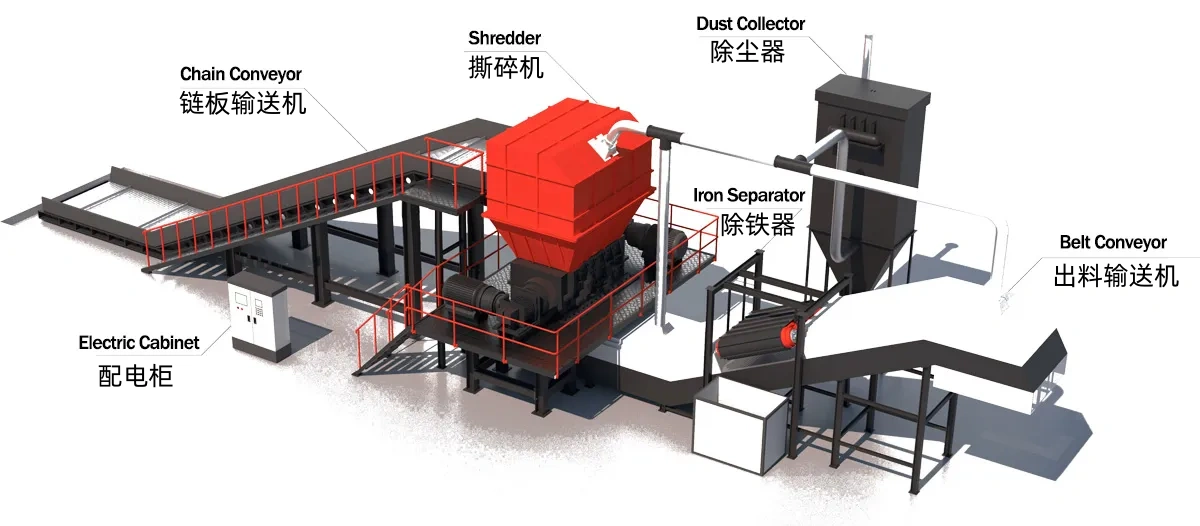

ZCH offers robust solutions for shredding metal waste from the waste, automotive and electrical industries, helping to reintegrate valuable raw materials into the production cycle.

The ubiquity of metal waste and the different physical properties (ductility, hardness, etc.) of different metal wastes require shredders with a wide range of material suitability. Some large metal recycling stations work at full capacity for long periods of time, so the stability and reliability of the metal shredder is also of paramount importance. zhongcheng machinery's metal shredders are designed to shred most scrap metal, be it drums, pipes, sheet metal, scrap aluminum alloy or car shells. All our metal shredders are renowned for their high availability and reliability, and our ready-to-use spare parts library gives you peace of mind.

A scrap metal shredder, also sometimes referred to as a metal scrap shredder, is a machine used for reducing the size of scrap metal.

Some examples of scrap metal materials that are commonly shredded are:

Tin cans / Aluminum cans / Aluminum waste / Tin box containers / Iron / Copper tube / Computer recycling / Bulk drums / Home appliance recycling / Television sets / Washing machines / Waste electrical.

The metal industry is a pioneer of the circular economy, as old products are collected, shredded and reused as a valuable raw material. The shredding of metals, whether aluminum, copper or steel, places high demands on modern recycling plants. Metal waste is abrasive, heavy and bulky, but with the right shredder it can be processed and recycled efficiently.

Choosing the right Industrial metal shredder involves considering several factors based on your specific needs and the type of material you plan to shred. Here’s a step-by-step guide to help you make an informed decision:

1. Material & Application Metal Type: Determine if you're shredding light materials (like copper or aluminum), heavy-duty steel, or mixed metals. The shredder must be capable of handling your specific metal scrap. Application: A shredder's role is to reduce scrap metal into smaller, more manageable pieces for recycling. Ensure the machine's design is suited for your specific type of scrap.

2. Performance & Output Throughput Capacity: This measures the volume of material the shredder can process per hour. High-capacity units are necessary for large-scale operations. Desired Output Size: Decide on the final particle size you need. Different shredding technologies produce different results. Power & Torque: The motor's power and torque are critical for efficiently breaking down dense and heavy scrap metals.

3. Technology & Components Shredding Technology: Choose between technologies like hammer mills or shear shredders, each with its own strengths for different materials and output sizes. Cutting Chamber: The size of the cutting chamber affects the ability to process larger, irregularly shaped pieces. Blade Material: Select blade materials like tungsten carbide for high wear resistance with abrasive metals or H13 steel for toughness with impact-heavy waste.

4. Reliability & Safety Durability & Construction: Opt for machines with robust construction and wear-resistant components designed to withstand heavy use in metal recycling operations. Safety Features: Look for features like emergency stop buttons, overload protection, and safety guards to ensure safe operation. Automation & Controls: Modern shredders often have advanced systems, including PLCs, remote monitoring, and automatic overload protection, which can enhance efficiency and reduce downtime.

5. Manufacturer & Cost Reputation & Quality: Choose a manufacturer with a good reputation, high-quality equipment, and a proven track record. After-Sales Service: Inquire about the manufacturer's warranty period, spare parts availability, and after-sales support. Cost-Effectiveness: Consider the equipment's price in relation to its performance and operating costs to find the best long-term value.

Cutters are bolted to the cutter base, which is welded to the rotor, easy to change the cutters.

Independent drive of double rotors, mutual feeding, multiple shredding, high shredding efficiency.

Integrated design of discharge screen and access door, hydraulic one-touch opening, easy maintenance.

By evaluating these features, you can determine which industrial metal shredder best suits your needs in terms of performance, efficiency, and reliability.

The Role of Smart Manufacturing in Producing High-Quality Metal Shredders

In metal shredding,smart manufacturing techniques are indispensable in achieving an unrivaled degree of precision, concentricity, and verticality in our shredders. By integrating these advanced technologies into the production process, every component of a metal shredder can be fashioned with superb dimensional accuracy and concentricity, which ensures a uniform thickness in the shredded output. Verticality ensures smooth and reliable operation throughout its service life.

A Closer Look at Metal Scrap Shredders

Metal scrap shredders are indispensable assets in recycling, turning bulky scrap metal into manageable pieces with their high-torque, multi-shaft design. These efficient and automated machines reduce operational costs and enhance safety by transforming unwieldy scraps into safe, more easily handled fragments. Crucially, metal shredders play a key role in size reduction, thereby streamlining the recycling process, fostering the reuse of valuable metal resources, and presenting an eco-friendly solution to metal waste management.

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| ZSD12 | 1-6 | 30-120 | 3000×2800×3000 |

| ZSD15 | 3-15 | 3600×2800×3000 | |

| ZSD20 | 8-25 | 4200×3000×3200 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.