The main function of the pre-shredder when processing materials is to perform preliminary, large-size crushing. It can quickly crush large, hard or difficult-to-handle materials into smaller pieces for subsequent transportation, storage, classification and reuse. The pre-shredder improves processing efficiency, reduces energy consumption and costs by reducing the volume of materials, and also helps to recycle and reuse resources, which is of great significance for promoting circular economy and sustainable development. The characteristics of pre-shredders in processing materials are mainly reflected in the following aspects:

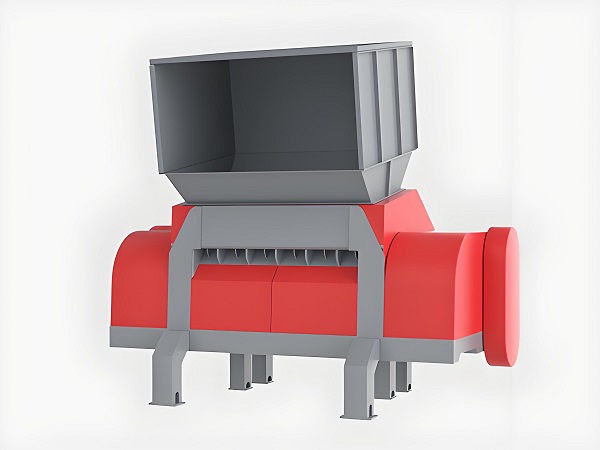

Pre-Shredder

1. Powerful crushing capacity

pre-shredders, especially large industrial pre-shredders, use high-strength blades and unique crushing mechanism design to give them powerful crushing capacity. This design can easily cope with large or hard materials such as scrap cars, metal waste, large plastic products, wood, etc. By shearing, tearing and crushing, pre-shredders can process these materials into smaller pieces or particles.

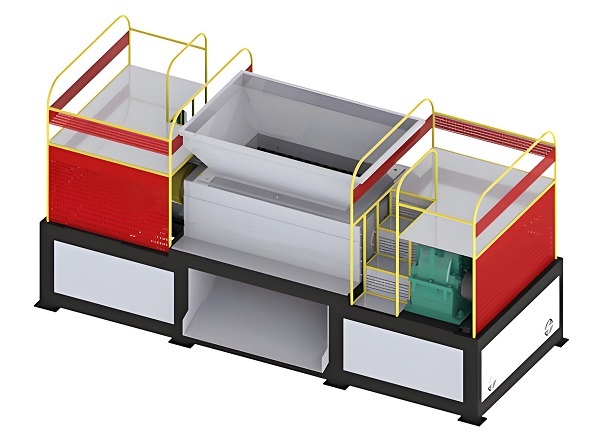

2. Adaptability and flexibility

Adjustability: pre-shredders usually have adjustable feed ports and crushing chamber designs to adapt to materials of different sizes and shapes. For large materials, the feeding port size can be adjusted or auxiliary devices (such as breaker hammers) can be used to assist the feeding, ensuring that the materials can enter the crushing chamber smoothly and be effectively processed.

Diverse crushing modes: Some advanced pre-shredders also have a variety of crushing modes to choose from, such as shearing, tearing and extrusion. These different crushing modes can be switched according to the nature of the material and the processing requirements to achieve the best crushing effect.

Pre-Shredder

3. High efficiency and energy saving

Processing efficiency: When processing large or hard materials, the pre-shredder can quickly break them into small pieces or particles, greatly improving the processing efficiency. This is especially important for occasions where large amounts of waste need to be processed quickly, such as industrial waste recycling and construction waste processing.

Energy saving and consumption reduction: Although processing large or hard materials requires greater power support, modern pre-shredders focus on energy saving and consumption reduction in design. By optimizing motor performance, improving the transmission system and adopting advanced control technology, energy consumption and operating costs can be reduced while ensuring the crushing effect.

Pre-Shredder

4. Stability and durability

Stable structure: pre-shredders are usually made of sturdy and durable materials, and the structure is stable and reliable. When processing large or hard materials, it can withstand greater impact and vibration, ensuring the stability and safety of equipment operation.

Wear-resistant parts: In addition to the blades, other key parts of the pre-shredder (such as bearings, spindles, etc.) are also made of materials with good wear resistance. These parts can resist wear and corrosion during long-term operation and extend the service life of the equipment.

PS: The pre-shredder exhibits strong crushing ability, good adaptability and flexibility, high efficiency and energy saving, and the advantages of stability and durability when processing materials. These characteristics make the pre-shredder have broad application prospects and important application value in the fields of solid waste treatment and resource recycling.

Save Time! Get A Detailed Quotation Quickly.