Preface: Correct installation procedures and precautions are essential for the stable operation and extended service life of the shredder blade. The installation procedures and precautions for the shredder blade are as follows:

A. Installation procedures for shredder blades

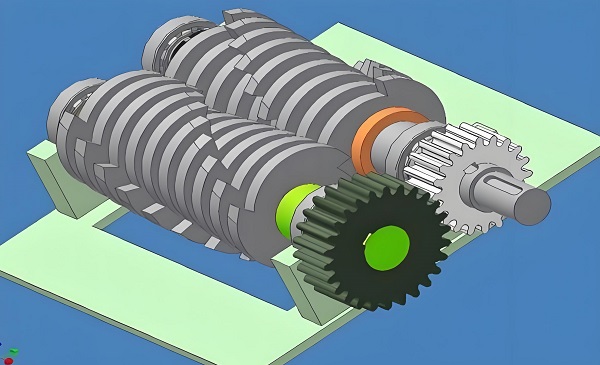

Shredder Blades

1. Power off and preparation:

Make sure the shredder is turned off and the power supply is disconnected to prevent accidents during installation.

Wear appropriate protective equipment, such as helmets, gloves, safety shoes, goggles, etc., to ensure the safety of operators.

Prepare the tools required to replace the blade, such as wrenches, screwdrivers, jacks, cranes, etc., and select appropriate tools according to the model and specifications of the shredder.

Check whether the surface of the new blade has defects such as damage and cracks to ensure the quality of the blade, and at the same time ensure that the quality and specifications of the new blade are consistent with the original blade to ensure the performance and stability of the shredder.

3. Remove the old blade:

Open the shredder casing, usually use a wrench or screwdriver to remove the bolts that fix the casing.

Find the old blade and observe how the blade is installed. Generally speaking, the shredder blade is fixed to the shaft by bolts.

Use a wrench or screwdriver to remove the bolts that fix the blades. Be careful to do it in the correct order to avoid deformation of the shaft due to uneven force.

Remove the old blade from the shaft and place it in a safe place. Be careful not to damage the surface of the blade and the shaft.

4. Install the new blade:

Place the new blade on the shaft, make sure the blade is installed in the correct position, and the blade's edge should face the correct direction to ensure the normal operation of the shredder.

Use bolts to fix the new blade on the shaft. When installing the bolts, pay attention to the tightening force to ensure that the blade is installed firmly, but not too tight to avoid damaging the shaft or blade.

Check the installation of the blade to ensure that the blade is installed flat and firmly without looseness or shaking.

5. Complete the installation:

Close the shredder casing and tighten the bolts that fix the casing.

Turn on the power and start the shredder for debugging. During the debugging process, pay attention to observe the operation of the blade and listen for any abnormal sounds.

If a problem is found, stop the machine immediately for inspection. After troubleshooting, continue debugging until the shredder runs normally and the blade works stably.

Shredder Machine

B. Precautions for installing shredder blades

1. Blade selection and inspection:

Choose the appropriate blade according to the model of the shredder and the characteristics of the material being processed. Different materials require different types of blades. For example, metal materials require blades with high hardness and good wear resistance, and plastic materials require sharp blades.

Before installation, be sure to carefully check the condition of the blade. If the blade has a notch or lost teeth, be sure to contact the manufacturer for replacement. Also pay attention to the angle of the blade. The blades are biased, so be sure to pay attention to the order of installation.

2. Details during installation:

When installing the blade, ensure the installation accuracy of the blade. The installation position, angle, spacing, etc. of the blade must meet the design requirements to ensure the performance and stability of the shredder.

Use a torque wrench to tighten the blade fixing bolts according to the torque value specified by the manufacturer. Overtightening may cause the bolts to break, and over-loosening may cause the blade to loosen, affecting the use effect and even causing safety accidents.

After the blade is installed, check the spacing between the shredder blade and the spacer and whether there are any foreign objects. Be sure to ensure that the thickness of the spacer is slightly thicker than the blade to avoid the two blades from being misaligned and biting too tightly and damaging the blade.

3. Safety and maintenance:

When replacing and installing the blade, be sure to handle it with care to avoid damage caused by collision of the claws. If the blade is too heavy, it requires multiple people to install it together.

Shredder Machine

After completing the installation, be sure to conduct a comprehensive inspection before the trial run, including the electrical system, transmission device, and safety protection facilities, etc., to ensure that everything is ready.

During operation, the operator must do a good job of protection. After multiple forward and reverse rotations, the machine can run without problems, and then put the machine into the working chamber for trial operation.

There should be no hard foreign objects such as steel blocks in the material to be shredded, so as to avoid the claws from breaking or the blades from cracking as a whole, thereby damaging the blades and the shredder.

PS: Correct installation and maintenance of the shredder blades are essential to ensure the safe operation of the equipment and extend its service life. During the installation process, be sure to follow the manufacturer's guidelines and precautions to ensure the safety and effectiveness of the operation.

Save Time! Get A Detailed Quotation Quickly.