Preface: The double-shaft waste shredder is an efficient and environmentally friendly waste disposal equipment, which is widely used in various waste disposal scenarios. The following is a detailed introduction to the double-shaft waste shredder, covering its working principle, structural composition, application scenarios, advantages and disadvantages, operation process and maintenance.

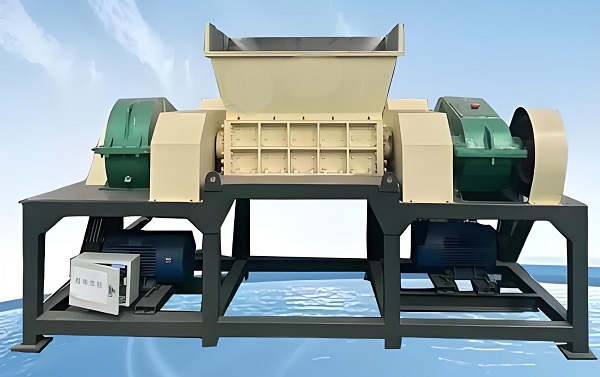

Double shaft shredder

A. Working principle

The working principle of the double-shaft waste shredder mainly depends on two knife shafts rotating in opposite directions and the staggered blades installed on them. During the rotation process, the blades reduce the input waste materials to a predetermined size through shearing, tearing and squeezing. The main shearing method is the shearing action of the adjacent moving knife blades, while the secondary shearing method is the tearing action of the moving knife teeth. This working principle enables the double-shaft waste shredder to handle waste materials of various shapes and materials, including waste plastics, waste rubber, wood, metal, etc.

B. Structural composition

The structural composition of the double-shaft waste shredder mainly includes the frame, rotating shaft, knife disc, blade, transmission device, feeding system, discharging system and control system.

1. Frame: The frame is the main frame of the double-shaft waste shredder, which plays the role of supporting and protecting other components. It is usually made of strong and durable steel to ensure the stability and durability of the machine.

2. Rotating shaft: The double-shaft waste shredder is usually equipped with two rotating shafts, which are located on both sides of the frame and placed in parallel. The rotating shaft is connected to the motor through a transmission device to drive the rotation of the blade system.

3. Cutter disc: Each rotating shaft is equipped with a cutter disc, and a series of blades are installed on the cutter disc. The shape and arrangement of these blades will be designed and adjusted according to the needs of processing different waste materials.

4. Blade: The blade is the core component of the double-shaft waste shredder, and they are directly involved in the shredding process of waste. The blade is usually made of high-quality alloy steel to ensure its hardness and wear resistance. The shape and number of blades will also be adjusted according to the needs of processing different materials.

5. Transmission: The transmission device transmits the power of the motor to the rotating shaft through gears, chains or belts. Its design must be efficient, reliable and durable to ensure the normal operation of the cutter disc and blades.

6. Feeding system: The feeding system is used to feed waste into the double-shaft waste shredder for processing. It usually includes components such as the feeding port, conveyor belt, and feeding wheel to ensure that the waste can enter the shredding area accurately and stably.

7. Discharging system: The discharging system is used to discharge the shredded and processed waste from the double-shaft waste shredder. It usually includes components such as the discharging port, conveyor belt, and discharging device to transport the shredded waste to subsequent processing links.

8. Control system: The control system is used to monitor and control the operation of the double-shaft waste shredder. It usually includes electrical control cabinets, panels, buttons, and sensors to ensure the safe and stable operation of the machine.

Double shaft shredder

C. Application scenarios

Double-shaft waste shredders have been widely used in many fields due to their high efficiency and environmental protection. The following are some typical application scenarios:

1. Urban waste treatment: double-shaft waste shredders can crush large pieces of waste for subsequent classification and processing.

2. Scrap metal recycling: It can efficiently process various types of waste metal products and realize resource recycling.

3. Wood processing industry: tear large pieces of wood into suitable sizes for reprocessing or as biomass fuel.

4. Electronic waste treatment: crush various electronic devices to achieve effective resource recycling.

5. Plastic recycling: crush waste plastics into particles for subsequent recycling.

6. Agricultural waste treatment: such as crushing agricultural waste such as straw for biomass energy or fertilizer production.

7. double-shaft waste shredders are also widely used in paper mills, medical waste treatment, industrial production scraps treatment, construction waste treatment, waste home appliance disassembly, garden pruning waste treatment and other fields.

D. Operation process

The operation process of the double-shaft waste shredder usually includes the following steps:

Double shaft shredder

1. Clear the body and surrounding materials: Before starting the machine, clear the body and surrounding materials of the shredder to ensure the hygiene of the work site.

2. Check the safety of the equipment: ensure the safety around the machine, employees wear safety helmets and protective gloves, and check whether the wires and switches are leaking electricity.

3. Connect the power: Turn on the power switch to ensure that the machine is powered on.

4. Idle test: Start the main motor and let the machine idle for a while to ensure the normal operation of the machine.

5. Feed gradually: After the machine idles normally, feed gradually and adjust the feeding speed.

6. Check the discharge port: During operation, regularly check whether the discharge port can discharge normally.

PS: Double-shaft waste shredders have been widely used in many fields due to their high efficiency, environmental protection, durability and other advantages. However, during use, it is also necessary to pay attention to its shortcomings and potential safety risks, and take corresponding operating procedures and maintenance measures to ensure the long-term stable operation of the equipment.

Save Time! Get A Detailed Quotation Quickly.