Under the promotion of the "zero waste city" construction and the policy of building waste resource utilization, efficient screening and resource recycling have become the core demands of the industry. 3% -8% of magnetic impurities (such as steel bars, iron wires, etc.) in construction waste can easily cause blockage of screening equipment, wear of broken parts, and substandard quality of recycled aggregates, seriously restricting the efficiency of production lines. As a key impurity removal and recycling equipment, the magnetic separator achieves precise separation of magnetic substances through the principle of electromagnetic induction, solving the multiple pain points of traditional screening. This article is based on the actual working conditions of construction waste treatment, systematically analyzing the four core roles of magnetic separators in iron purification, resource recovery, equipment protection, and quality and efficiency improvement. Combined with selection optimization strategies, it provides practical references for the industry to improve the level of resource utilization and promote green and low-carbon development.

A. The core pain points of construction waste screening and the positioning of magnetic separators

Construction waste is mainly composed of a mixture of concrete blocks, bricks, steel bars, wood, plastic, metal fittings, etc. Among them, magnetic substances such as steel bars, iron wires, and metal pipes account for about 3% -8% (with significant differences in construction waste from different sources). During the screening process, if these magnetic impurities are not removed in a timely manner, they can cause multiple problems: firstly, entanglement and blockage of the screen mesh and transmission components of screening equipment (such as drum screens and vibrating screens), leading to equipment shutdown for maintenance and reducing screening efficiency; Secondly, mixing with recycled aggregates can affect the quality of subsequent recycled products and fail to meet the standards for building aggregates; The third is to increase the wear and tear of crushing equipment (such as hammer crushers and cone crushers), and even cause equipment failures.

As a key impurity removal and recycling equipment in the screening process of construction waste, the magnetic separator is based on the principle of electromagnetic induction, which adsorbs magnetic substances through a magnetic field to achieve efficient separation of magnetic impurities and non-magnetic materials. Its core positioning is to purify the screening environment, recycle valuable resources, protect subsequent equipment, and improve the quality of recycled aggregates, becoming an indispensable key link in the production line of construction waste resource utilization.

B. The four core functions of magnetic separators in screening construction waste

1. Magnetic substances such as steel bars and iron wires in construction waste have high hardness and strong toughness. If they directly enter the screening equipment, they are prone to entangle with the rotating shaft of the drum screen, the exciter of the vibrating screen, or get stuck in the aperture of the screen, causing equipment overload and shutdown. Magnetic separators intercept magnetic impurities in advance through high-intensity magnetic fields, avoiding such problems from the source.

According to different installation locations, magnetic separators can be divided into "pre magnetic separation" and "secondary magnetic separation": the pre magnetic separation equipment is installed in front of the screening machine to process construction waste with larger particle sizes (over 50mm), quickly separate large steel bars and metal components, and avoid them from entering the screening machine and causing blockages; The secondary magnetic separation equipment is installed after the screening machine to finely remove iron and remove small iron wires and metal debris from the crushed fine particle materials (0-50mm). Taking a construction waste treatment plant as an example, after installing a pre magnetic separator, the blockage failure rate of the drum screen decreased from 3 times per week to 1 time per month, and the equipment start-up rate increased by more than 25%.

The magnetic field strength of the magnetic separator can be adjusted according to the characteristics of the material. For magnetic substances in construction waste, the magnetic field strength is usually set to 8000-12000GS (Gauss), with an adsorption efficiency of over 98%. It can effectively remove magnetic impurities with a particle size of 0.5mm or more, ensuring the continuous and stable operation of the screening equipment.

2. Recycling valuable metals to improve resource utilization efficiency

Magnetic metals such as steel bars and iron wires in construction waste have high recycling value. Magnetic separators achieve resource recovery through efficient adsorption, creating additional economic benefits for enterprises. According to the scale of construction waste treatment, the metal recovery rate of the magnetic separator can reach over 95%. Taking a construction waste production line that processes 1000 tons of construction waste per day as an example, about 30-80 tons of metals such as steel bars and iron wires can be recycled per day. Calculated at the market metal recycling price, the annual income increase can reach several million yuan.

After centralized collection and packaging, the recycled metals can be directly sold to steel plants for further refining or processed into recycled metal products, achieving resource recycling. In addition, for construction waste containing small amounts of non-ferrous metals (such as aluminum and copper), eddy current separators can be used in combination with magnetic separators to separate magnetic metals first, and then recycle non-ferrous metals through eddy current separators, further improving resource recovery efficiency and meeting the requirements of resource recycling under the "dual carbon" policy.

3. Protect subsequent crushing equipment and reduce operation and maintenance costs

After screening construction waste, qualified aggregates need to be further crushed in a crusher to meet the particle size requirements of recycled aggregates. If there are residual magnetic impurities in the aggregate, it will seriously wear down the hammer head, lining plate, crushing wall and other vulnerable parts of the crusher, and even cause serious faults such as hammer shaft fracture and motor burnout.

The iron removal function of the magnetic separator can effectively protect the subsequent crushing equipment: on the one hand, it avoids direct collision between magnetic impurities and the core components of the crusher, reduces wear of vulnerable parts, and extends the service life of the hammer head and lining plate by more than 30%; On the other hand, reducing equipment downtime caused by foreign object impact, and minimizing maintenance costs and production losses. Taking the hammer crusher as an example, when no magnetic separator is installed, the replacement cycle of the hammer head is about 800 hours. After installing a magnetic separator, the replacement cycle is extended to more than 1200 hours, saving hundreds of thousands of yuan in the annual cost of purchasing vulnerable parts.

4. Improve the quality of recycled aggregates and expand their application scenarios

The quality of recycled aggregate directly determines its application range, and the content of magnetic impurities is one of the key indicators to measure the quality of recycled aggregate. According to the standard "Recycled Aggregates for Concrete" (GB/T 25177-2010), the magnetic substance content of Class I recycled aggregates should be ≤ 0.05%, Class II ≤ 0.1%, and Class III ≤ 0.3%. The magnetic separator can accurately remove iron and control the content of magnetic substances in recycled aggregates within the standard range, improving the quality of recycled aggregates.

High quality recycled aggregates can be widely used in concrete mixing, road base laying, brick making and other scenarios: when used for ready mixed concrete, a low content of magnetic impurities will not affect the compressive strength and durability of the concrete; When used for road construction, it can reduce the wear and tear of construction equipment caused by aggregates and improve the quality of road engineering. If the magnetic impurities in the recycled aggregate exceed the standard, it can only be used for low-grade backfill projects, with limited application scenarios and significantly reduced economic value. The iron removal function of magnetic separators can help enterprises produce high-grade recycled aggregates, expand application scenarios, and enhance product added value.

C. Application selection and optimization of magnetic separator in screening construction waste

1. Principle of adaptability selection

According to the process characteristics of the construction waste treatment production line, the selection of magnetic separators should follow the principles of "adapting to production capacity, precise iron removal, and convenient operation":

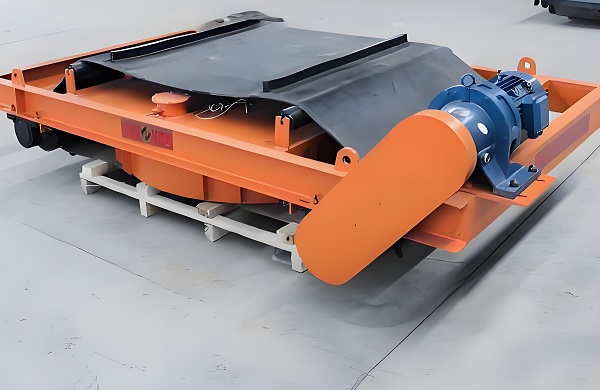

Selection based on processing capacity: Small production lines (daily processing capacity ≤ 500 tons) can choose drum type magnetic separators (model such as CTB-612) with processing capacity of 10-50t/h; Large production lines (with a daily processing capacity of ≥ 1000 tons) should use wide drum magnetic separators (such as CTB-1024) with a processing capacity of 100-300t/h to ensure compatibility with the production line capacity.

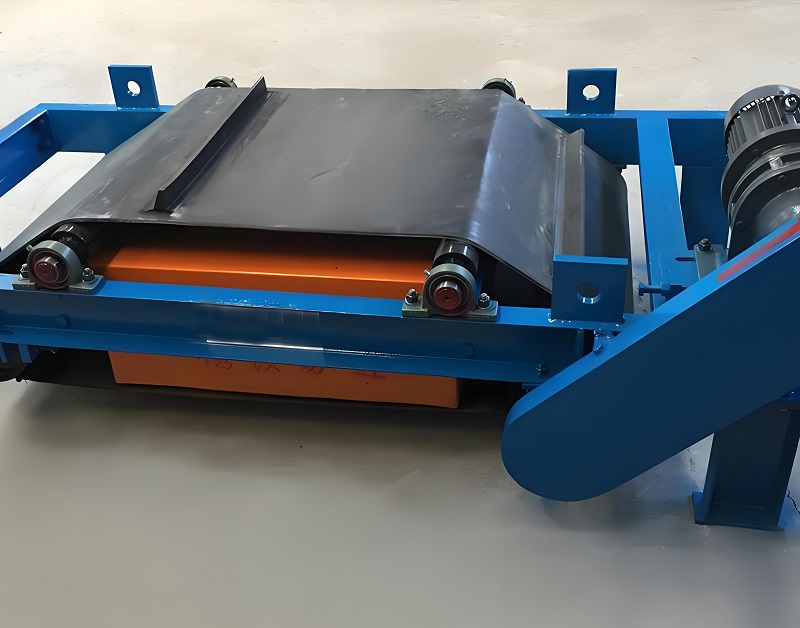

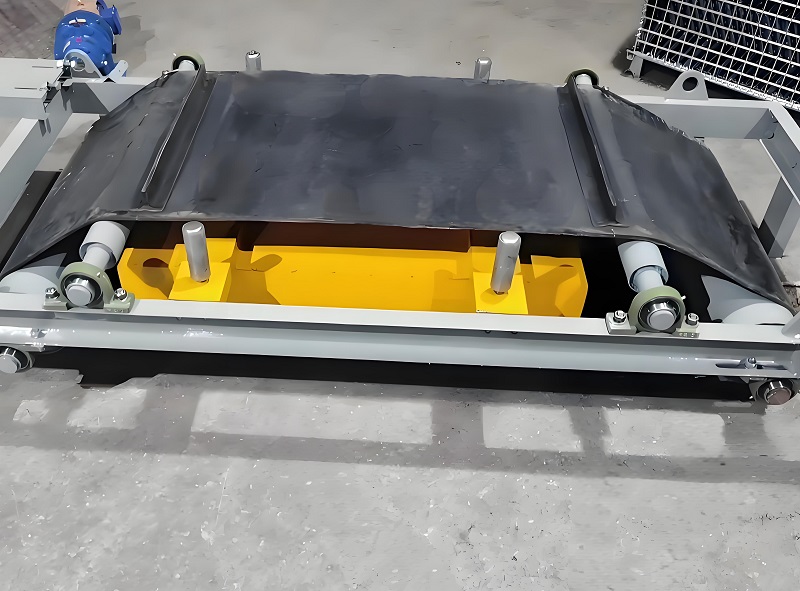

Selection based on material status: For block shaped construction waste (particle size ≥ 50mm), a suspended magnetic separator is selected and installed above the belt conveyor, without the need to adjust the production line layout; For fine particle aggregates (particle size ≤ 50mm), a drum type magnetic separator is selected and integrated with a belt conveyor for more thorough adsorption.

Selection based on installation location: For the pre magnetic separation process, a strong magnetic field separator (with a magnetic field strength of 10000-12000GS) is selected to separate large magnetic substances; The secondary magnetic separation process uses a medium strong magnetic field separator (magnetic field strength 8000-10000GS) to remove small magnetic impurities.

2. Application optimization strategy

Dynamic adjustment of magnetic field strength: Adjust the magnetic field strength of the magnetic separator in real-time based on the content and particle size of magnetic substances in construction waste. For example, when dealing with demolition construction waste (with high steel content), the magnetic field strength should be appropriately increased; When dealing with decoration and construction waste (with less magnetic material), reduce the magnetic field strength to save energy consumption.

Optimization of installation angle: The installation angle between the suspended magnetic separator and the belt conveyor should be controlled between 15 ° -20 ° to ensure that the magnetic substance can be smoothly adsorbed and dropped into the collection box; The drum speed of the drum type magnetic separator should match the speed of the belt conveyor (usually 1-3r/s) to avoid material accumulation on the surface of the drum.

Regular maintenance: Regularly clean the adsorption surface of the magnetic separator, remove residual magnetic substances and dust, and avoid attenuation of magnetic field strength; Check the sealing of the magnet to prevent damage from moisture and corrosive substances in construction waste, ensuring long-term stable operation of the equipment.

D. The industry application value and development trend of magnetic separators

Under the promotion of the "zero waste city" construction and the policy of utilizing construction waste resources, the application value of magnetic separators has become increasingly prominent. It not only solves the pain point of iron removal in construction waste screening, ensuring the efficient operation of production lines, but also realizes the recycling and utilization of metal resources, improves the quality of recycled aggregates, and provides key technical support for the resource utilization of construction waste.

In the future, magnetic separators will develop towards intelligence, high efficiency, and energy conservation: firstly, integrated intelligent monitoring systems will be used to monitor magnetic field strength, processing capacity, and other parameters in real time through sensors, achieving automatic adjustment and fault warning; The second is to use new permanent magnet materials (such as neodymium iron boron permanent magnets) to enhance magnetic field strength and stability, and reduce energy consumption; The third is to develop multifunctional joint sorting equipment, integrating functions such as magnetic separation, eddy current sorting, and wind sorting, to achieve efficient separation of magnetic metals, non-ferrous metals, and non metals in construction waste, further improving resource recovery efficiency and promoting high-quality development of the construction waste resource utilization industry.

Magnetic separators play an irreplaceable core role in the screening of construction waste: through the dual guarantee of pre magnetic separation and secondary magnetic separation, more than 98% of magnetic impurities are efficiently removed, significantly reducing equipment failure risks and improving production line start-up rates; Simultaneously recycling high-value magnetic metals can increase annual income by millions of yuan, balancing economic benefits and resource recycling. Its precise iron removal function can also control the content of magnetic substances in recycled aggregates within the national standard range, expand application scenarios, and enhance product added value. In the future, with the upgrading of intelligent and energy-saving technologies and the development of multifunctional joint sorting equipment, magnetic separators will further empower the construction waste resource utilization industry, providing stronger technical support for achieving the goals of "reduction, harmlessness, and resource utilization".

Save Time! Get A Detailed Quotation Quickly.