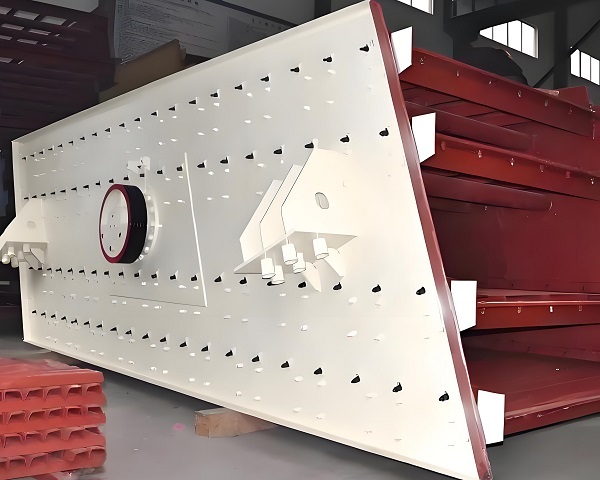

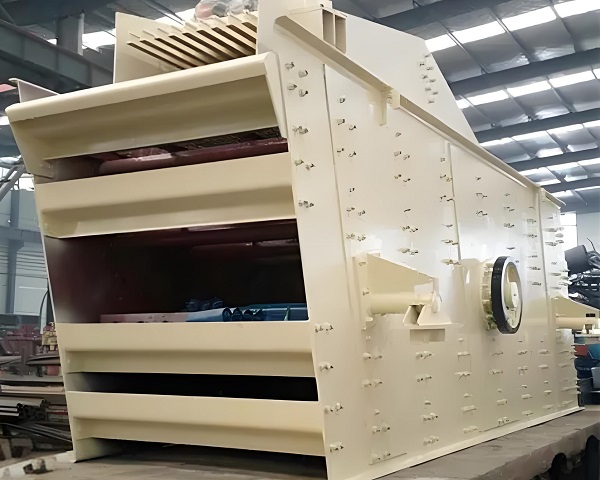

Vibrating screens, as core equipment for material classification in industries such as mining, chemicals, and building materials, operate under harsh conditions of high-frequency vibration, dust erosion, and load fluctuations, making their maintenance a constant challenge. These challenges not only affect equipment operating efficiency but can also lead to increased maintenance costs, prolonged downtime, and even safety accidents.

This article systematically outlines the core difficulties in vibrating screen maintenance and proposes targeted solutions based on practical application scenarios, providing a reference for equipment operation and maintenance in the industry.

Core Difficulties in Vibrating Screen Maintenance

1. High Difficulty in Diagnosing Faults in Key Components

The core components of a vibrating screen, such as the vibrating motor, bearings, screen mesh, and springs, are prone to failure. However, due to the high-frequency vibration during operation, traditional detection methods struggle to accurately pinpoint the root cause of the fault. For example, bearing wear and motor rotor imbalance can both cause abnormal vibration, and relying solely on sensory judgment can easily lead to misdiagnosis. Initially, screen damage may be covered by material, making it difficult to detect with the naked eye; by the time a significant decrease in screening efficiency occurs, a large amount of material has already been wasted. Furthermore, some components are hidden inside the equipment, requiring considerable time for disassembly and inspection, further increasing the difficulty of diagnosis.

2. Stringent Technical Requirements for Vibrating Motor Maintenance

As the power source of the vibrating screen, the quality of its maintenance directly determines the stability of the equipment's operation. The main difficulties in maintaining this component lie in two aspects: First, the rotor imbalance correction requires high precision. If the correction deviation exceeds the allowable range, it will lead to increased equipment vibration, thereby damaging other components. Second, the winding repair process is complex. The windings of the vibrating motor are subjected to high-frequency vibration for a long time, which can easily lead to problems such as loose coils and damaged insulation. During repair, the number of winding turns and wiring method must be strictly controlled; otherwise, it will affect the motor's power output and may even cause short-circuit faults.

3. Difficulty in Precision Control for Screen Replacement and Installation

The screen is the core component of the vibrating screen for material classification. Its replacement and installation are high-frequency tasks in maintenance, but the operation is particularly difficult. On the one hand, the screen mesh is subjected to long-term impact and friction from materials, making its edges prone to deformation. Disassembly requires overcoming issues such as material adhesion and bolt corrosion, especially with the heavy weight of large vibrating screens, making the disassembly process time-consuming and labor-intensive. On the other hand, installation accuracy directly affects screening efficiency. Insufficient screen tension will cause secondary vibrations during operation, leading to material accumulation; excessive tension may cause the screen mesh to crack, shortening its service life.

4. Maintenance Environment Challenges under Harsh Working Conditions

Vibrating screens are widely used in mining, construction waste processing, and other similar scenarios. Maintenance environments are often characterized by high levels of dust, noise, and space constraints. Dust can penetrate maintenance tools and equipment, affecting maintenance accuracy; high-frequency noise not only harms the health of maintenance personnel but also interferes with fault diagnosis; some equipment is installed in confined spaces or at high altitudes, increasing the difficulty of component handling and disassembly, and creating safety hazards. Furthermore, extreme weather conditions (high temperatures, rain, snow) during outdoor operations further restrict maintenance efficiency.

5. The Dilemma of Balancing Maintenance Costs and Downtime Losses The core components of vibrating screens (such as vibrating motors and large bearings) have high procurement costs, and frequent replacements can lead to a surge in maintenance costs. However, excessive or delayed maintenance may exacerbate the problem and cause equipment downtime. For companies with continuous production, a one-hour downtime can result in tens of thousands of yuan in economic losses. How to minimize downtime and control maintenance costs while ensuring maintenance quality has become a significant challenge for operation and maintenance management.

Strategies for Addressing the Difficulties in Vibrating Screen Maintenance

Introducing Intelligent Detection Technology to Improve Fault Diagnosis Accuracy To address the difficulty of fault diagnosis, intelligent detection equipment such as vibration sensors and temperature sensors can be introduced to monitor the operating parameters (vibration frequency, temperature changes) of key components such as vibrating motors and bearings in real time. Data analysis can then be used to predict fault trends. For example, using vibration analysis software to perform spectral analysis of the equipment's vibration signals can accurately distinguish between different types of faults such as bearing wear and rotor imbalance; using infrared thermometers to detect the temperature of motor windings and bearings can promptly identify potential overheating. Simultaneously, establishing equipment maintenance records to document the manifestations, causes, and solutions for each fault provides a reference for subsequent diagnosis.

2. Standardize Repair Processes and Enhance the Quality of Key Component Repair

For vibratory motor repair, standardized processes must be strictly followed: rotor imbalance correction should be performed using a dynamic balancing test machine to ensure correction accuracy within 0.02mm; when repairing windings, use enameled wire of the same specifications as the original, strictly control winding tension and wiring process, and perform insulation and withstand voltage tests after repair to avoid short circuits. For bearing repair, use a dedicated puller during disassembly to avoid damage caused by rough handling; clean and lubricate the bearing before installation, select a suitable grease (e.g., lithium-based grease for high-temperature conditions), and control the amount of grease used to prevent malfunctions caused by improper lubrication.

3. Optimize Screen Installation Process and Improve Installation Accuracy

To solve the difficulties of screen replacement and installation, a modular screen structure can be adopted to simplify the disassembly process. When replacing screens, first clean any remaining material from the screen box and check for deformation of the screen frame. If deformation is found, correct it promptly. During installation, use specialized tensioning tools (such as tension bolts and wedges) to control the screen tension. Generally, the screen should not sag significantly and should rebound quickly after being pressed. Simultaneously, install protective pads on the screen edges to reduce damage from material impact. Regularly check the screen tension and adjust it promptly if loosening is found to extend the screen's lifespan.

4.Improve the maintenance environment to ensure maintenance safety and efficiency. To address the challenges of harsh working conditions, it is necessary to protect the maintenance environment: clean the work area of dust before maintenance and erect a temporary dust-proof shed; maintenance personnel should wear dust masks, earplugs, and other protective equipment to reduce dust and noise hazards; for work at heights or in confined spaces, erect safety scaffolding and use small lifting equipment to assist in the handling of components, avoiding accidents caused by manual handling. In addition, equip the work area with portable maintenance tools (such as rechargeable wrenches and small hydraulic jacks) to improve the flexibility of working in confined spaces; when working outdoors, pay attention to the weather forecast in advance and take precautions against rain and sun. 5. Establish Full Lifecycle Management to Balance Maintenance Costs and Downtime Losses Implement full lifecycle management for vibrating screens, developing preventative maintenance plans based on equipment operating time and intensity. Regularly inspect and maintain key components to avoid sudden failures. For example, lubricate bearings every 3000 hours of operation and check screen wear every 10000 hours, replacing components nearing failure in advance. Simultaneously, optimize spare parts management, stocking commonly used wear parts (such as screens, seals, and small bearings) to shorten repair waiting time. For high-value components, remanufacturing technology can be used to reduce procurement costs. Furthermore, establish a cooperation mechanism with equipment manufacturers to quickly resolve complex faults with their technical support, minimizing downtime losses.

The challenges of maintaining vibrating screens stem from various factors, including equipment structural characteristics, harsh operating conditions, and operation and maintenance management. Overcoming these challenges requires a concerted effort of technological upgrades, process standardization, and management optimization. By introducing intelligent detection technology, standardizing maintenance processes, optimizing installation procedures, improving the maintenance environment, and establishing a full lifecycle management system, maintenance quality and efficiency can be effectively improved, while reducing maintenance costs and downtime losses. In the future, with the application of intelligent and modular technologies in the vibrating screen field, maintenance work will develop towards precision and efficiency, providing strong support for the sustainable development of the industry.

Save Time! Get A Detailed Quotation Quickly.