Editor's note: At a time when environmental awareness is increasing, iron removers help recycle resources and reduce the pollution of iron-containing waste to the environment. As a device used to remove magnetic impurities from materials, iron removers have broad application prospects. With the continuous development of industrial production, the quality requirements for raw materials and products are getting higher and higher. Iron removers can effectively improve the purity of materials and reduce the wear and damage of production equipment caused by magnetic impurities, thereby improving production efficiency and product quality. The application of iron removers is particularly important in garbage disposal, mining, metallurgy, electricity, chemical industry, building materials and other industries. This article introduces the application field of iron removers, the technical characteristics of iron removers, the safety measures in the maintenance of iron removers, the advantages of Zhongcheng iron removers, etc.

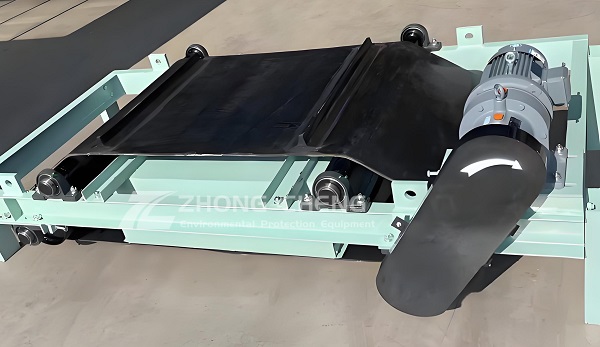

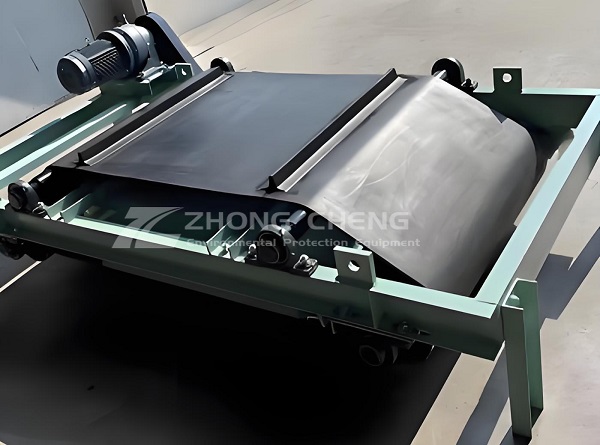

Zhongcheng Machinery's Iron Remover

A. Application scope of iron removers:

Iron removers are widely used in metallurgy, mining, coal preparation plants, power plants, ceramics, glass, cement, building materials, chemicals, food and feed processing industries. In the emerging garbage disposal industry, iron removers are also needed to recover steel from waste. Iron removers have been used in large steel enterprises, as well as metal mines, power plants, light industry, refractory materials and other industries, and have played a huge role.

Iron removers are suitable for material feeding and iron removal in various industries, and can achieve continuous absorption and discarding of iron.

Zhongcheng Machinery's Iron Remover

B. Safety measures during the maintenance of iron removers

1. Formulate a system to strictly implement the system of who cuts off power and who supplies power

2. Before maintenance, the belt must stop running, and it is strictly forbidden to repair the belt while it is running

3. Before maintenance, the iron on the iron remover must be cleaned and the surrounding impurities must be cleaned

4. When climbing for maintenance, maintenance personnel must use safety ropes, safety belts, etc.

5. Before maintenance, maintenance personnel must understand the working principle of the equipment and the performance of the parts inspected by the iron remover, and prepare the tools needed for maintenance.

Zhongcheng Machinery's Iron Remover

C. Technical characteristics of iron removers

Iron removers are equipment used to remove magnetic impurities in materials, with the following technical characteristics:

1. Strong magnetic force: using high-performance magnetic materials, it can generate a strong magnetic field, effectively adsorb magnetic impurities in materials, and ensure the iron removal effect.

2. Various types: including permanent magnetic iron removers and electromagnetic iron removers. Permanent magnetic iron removers have the advantages of simple structure, low operating cost and convenient maintenance; electromagnetic iron removers have the characteristics of adjustable magnetic field strength and strong adaptability, which can be selected according to different application scenarios and needs.

3. Efficient iron removal: It can quickly separate magnetic impurities from materials, improve the purity and quality of materials, and reduce equipment wear and failure in subsequent production processes.

4. High degree of automation: Equipped with advanced control systems, it can realize automatic operation and monitoring, improve production efficiency, and reduce the labor intensity of manual operation.

5. Strong durability: It adopts high-quality materials and advanced manufacturing processes, has good wear resistance and corrosion resistance, and can operate stably for a long time in harsh working environments.

6. Easy to install and maintain: The structure is reasonably designed, easy to install, and the maintenance cost is low. It only needs to be checked and cleaned regularly to ensure the normal operation of the equipment.

7. Wide range of applications: It can be widely used in material iron removal in mining, metallurgy, electricity, chemical industry, building materials, food and other industries, and can meet the iron removal needs of different industries and materials.

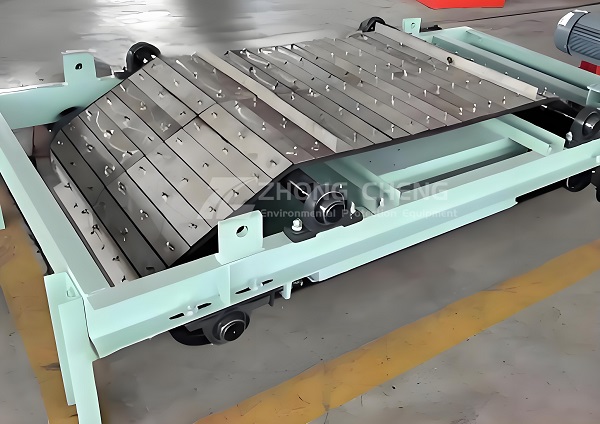

Zhongcheng Machinery's chain plate type iron remover

D. Features of Zhongcheng Machinery's iron remover:

Zhongcheng Machinery's Iron Remover

1. This machine uses high-strength rare earth neodymium iron boron to form a strong magnetic core with a strong magnetic field and high magnetic field gradient.

2. It is suitable for relatively small places where the installation space is limited. The equipment itself is light and convenient for hanging installation. It is easy to move and replace to another place for work.

3. The structure is simple, easy to maintain, the parts are streamlined, and the maintenance cost is reduced.

4. The shaft drive motor is used to effectively solve the chain breakage and chain drop of the sprocket chain drive or the belt breakage and slippage of the belt drive.

5. The automatic iron unloading belt adopts a high-strength ring-shaped integrated rubber belt, and the integrated scraper can easily complete the iron unloading operation.

6. Stainless steel guard plates are designed around the magnetic core to effectively prevent ferromagnetic objects from splashing during iron unloading, causing losses and accidental injuries.

7. The support bracket can be supported to meet different installation methods, protect the belt from external damage, and extend the life of the belt.

8. The appropriate size and performance can be tailored according to the user's on-site space and requirements.

Main technical parameters of Zhongcheng Mechanical Iron Remover:

| Model Parameter Project | Adaptation Bandwidth mm | Rated Lifting Height h=mm | Material Thickness ≤mm | Excitation Power ≤kw | Magnetic Field Strength ≥mT | Drive Power ≤kw | Adaptability Belt speed ≤m/s | Weight kg | Dimensions mm | ||||

| A | B | C | D | E | |||||||||

| ZCIR-5 | 500 | 150 | 100 | 1.2 | 60 | 1.2 | 4.5 | 1200 | 1900 | 900 | 800 | 650 | 1050 |

| ZCIR-6 | 600/650 | 180 | 130 | 1.8 | 60 | 1.5 | 1600 | 2100 | 1000 | 850 | 700 | 1170 | |

| ZCIR-6.5 | 650 | 200 | 150 | 2.0 | 70 | 2.2 | 1900 | 2200 | 1050 | 900 | 750 | 1270 | |

| ZCIR-8 | 800 | 250 | 200 | 3.3 | 70 | 2.2 | 2600 | 2350 | 1150 | 970 | 810 | 1420 | |

| ZCIR-10 | 1000 | 300 | 250 | 4.7 | 70 | 3.0 | 3650 | 3100 | 1400 | 1080 | 810 | 1580 | |

| ZCIR-12 | 1200 | 350 | 300 | 6.8 | 70 | 4.0 | 4550 | 3250 | 1500 | 1200 | 940 | 1780 | |

| ZCIR-14 | 1400 | 400 | 350 | 8.9 | 70 | 4.0 | 6390 | 3500 | 1945 | 1300 | 940 | 1950 | |

| ZCIR-16 | 1600 | 450 | 400 | 13.5 | 70 | 5.5 | 7950 | 3650 | 2010 | 1400 | 940 | 2180 | |

| ZCIR-18 | 1800 | 500 | 450 | 18 | 70 | 5.5 | 9000 | 3850 | 2400 | 1500 | 940 | 2315 | |

| ZCIR-20 | 2000 | 500 | 500 | 22 | 70 | 5.5 | 9400 | 3950 | 2800 | 1600 | 940 | 2400 | |

Zhongcheng Machinery's magnetic separator series products include production magnetic separators, dry magnetic separators, wet magnetic separators, iron removers, permanent magnetic iron removers, electromagnetic iron removers and other iron removal equipment. With well-equipped laboratories and laboratories, we hire industry experts to preside over experiments and tests, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

PS: The iron remover has the technical characteristics of strong magnetic force, various types, high iron removal efficiency, high degree of automation, strong durability, convenient installation and maintenance, and a wide range of applications. It is an important equipment to ensure the purity of materials and safe operation of equipment during the production process. With the continuous improvement of environmental awareness, the iron remover will also play an important role in resource recovery and environmental protection. It can help recover valuable metals in waste materials, reduce resource waste, and reduce pollution to the environment. The iron remover has a wide range of application needs and market potential, and its application prospects are very broad.

Save Time! Get A Detailed Quotation Quickly.