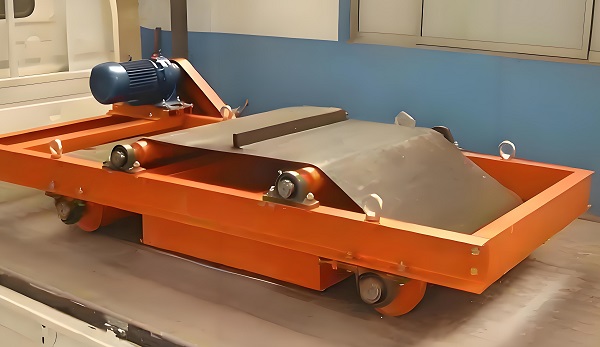

Editor's Note:The flat plate iron remover (also known as the flat plate magnetic separator) is a kind of iron removal equipment with simple structure, small size and low price. Its main working principle is to use the magnetic plate to generate a magnetic field to adsorb the iron impurities in the material flowing through the magnetic plate, so as to achieve the purpose of iron removal. The adsorbed iron impurities are usually removed by manual regular cleaning. The flat plate iron remover is usually installed in an inclined chute. When the material flows through the magnetic plate, the iron impurities will be attracted by the magnetic plate, and the cleaned material will flow from the discharge port to the next process. The iron removal effect of this equipment is affected by many factors such as the installation position, angle, material flow rate, and material layer thickness.

Flat plate iron remover

The flat plate iron remover (flat plate magnetic separator) is characterized by the simplest structure, small size and low price. The flat plate iron remover is widely used in various occasions where iron removal is required, such as garbage sorting, metallurgy, mining, coal preparation plants, power plants and other industries. Its advantages are simple operation and convenient maintenance, and it can effectively remove iron impurities in the material to ensure the normal operation of subsequent equipment. The following introduces the working principles and technical features of several iron removers:

Flat plate iron remover

A. Working principle of flat plate automatic iron remover:

The flat plate iron remover is installed in an inclined chute. When the material flows through the magnetic plate, the iron impurities are attracted by the magnetic plate. The cleaned material flows to the next process from the discharge port.

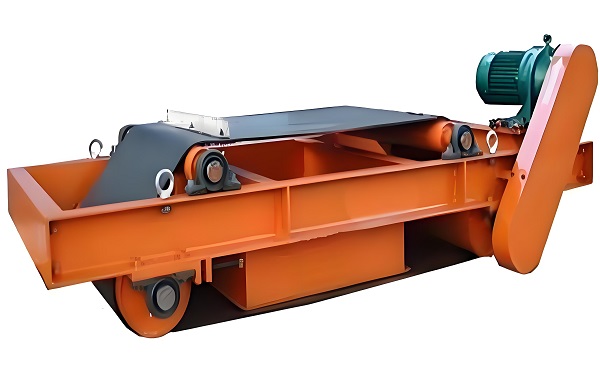

Automatic iron remover: When the bulk material transported by the belt conveyor passes through the magnetic separator installed on the tail bracket, the ferromagnetic debris in the material is attracted, and the ferromagnetic debris is dragged to the electric roller by the iron discarding belt to be unloaded, so as to achieve the purpose of automatic iron removal.

Flat plate iron remover

B. Technical features of flat plate automatic iron remover:

1. The magnetic circuit adopts computer simulation design, with deep magnetic penetration and strong magnetic force.

2. Special air duct design, axial flow fan forced air cooling, large air volume, high air pressure, so that the coil dissipates heat quickly, the temperature rise is low, and the difference between the cold and hot magnetic fields is small.

3. The coil adopts advanced varnish insulation and curing treatment technology to protect the coil from dust and harmful gas erosion, improve the insulation performance of the whole machine, and ensure long-term continuous operation without aging.

4. Automatic iron unloading, easy maintenance, drum waist drum structure, with automatic belt deviation correction function, special fully sealed bearing seat, can achieve long-term trouble-free operation.

5. The product has good matching, the rectifier equipment is fully functional, with manual and centralized control functions, which can meet the use requirements of various occasions.

Flat plate iron remover

C. Suspended magnetic separation iron remover

Suspended magnetic separation iron remover is a kind of equipment that can generate strong magnetic field attraction to remove ferromagnetic impurities mixed in the material, and is used in conjunction with various conveyors. It is mainly composed of permanent magnetic core, discarded iron belt, reduction motor, frame, drum and other parts. During the working process, the iron remover automatically throws the ferromagnetic material adsorbed on the unloading belt into the iron collection box, without power outage and manual cleaning, realizing the automation of iron removal. Product advantages of suspended magnetic separation iron remover:

1. Double pole structure, high magnetic field strength, large gradient and strong suction.

2. The equipment itself is light in weight, convenient for hanging installation, easy to move and replace to another occasion for work.

3. Simple structure, convenient maintenance, streamlined components, and reduced maintenance costs.

4. Automatic belt unloading can ensure long-term trouble-free continuous operation.

5. The motor is used to directly drive the drive shaft, which effectively solves the chain breakage and chain drop of the sprocket chain drive or the belt breakage and slippage of the belt drive.

Flat plate iron remover

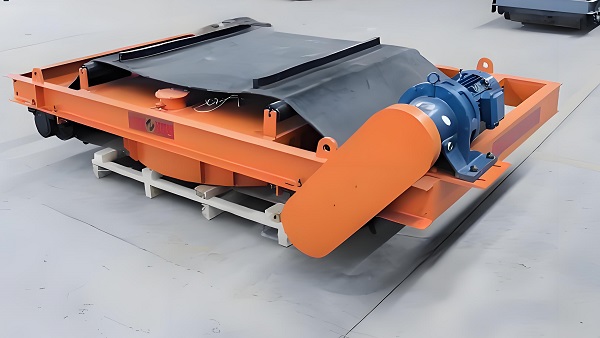

D. Oil-cooled self-unloading electromagnetic iron remover

The oil-cooled self-unloading electromagnetic iron remover is an iron unloading mechanism composed of a drive motor, a roller, and an iron unloading tape with a scraper added to the crude oil-cooled suspension electromagnetic iron remover. It has the advantages of strong magnetic force, fast heat dissipation, dustproof, rainproof, corrosion-resistant, continuous operation, and low maintenance cost. Since its launch, it has won the praise of users for its easy operation, low failure rate, and low maintenance. Technical features of oil-cooled self-unloading electromagnetic iron remover

1. The special design of the excitation coil is conducive to the transfer of heat to the transformer oil, effectively reducing the temperature of the coil.

2. The coil insulation is F-grade, using a new high-temperature heat-conducting oil, the oil circuit design is reasonable, unobstructed, fast circulation, and high heat dissipation efficiency.

3. The coil is completely immersed in the sealed cooling oil, with excellent dust, moisture and corrosion resistance.

4. The corrugated heat dissipation fins greatly increase the heat dissipation area, and the temperature rise of the coil is ≤ 70℃ for long-term continuous operation.

5. Automatic iron unloading, easy maintenance, drum waist drum structure, with belt automatic deviation correction function, special fully sealed bearing seat, can achieve long-term trouble-free operation

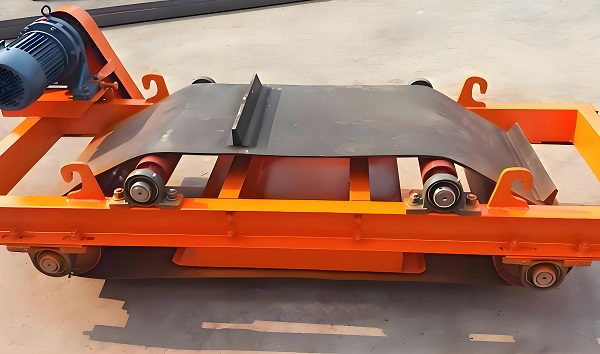

E. Structural characteristics and working principle of double-pole iron remover

Double-pole iron remover is a fast iron removal equipment, widely used in garbage sorting, power, mining, metallurgy and other industries. The following is a detailed introduction to the double-pole iron remover:

Flat plate iron remover

1. Product structure: The double-pole iron remover consists of two independent left and right explosion-proof magnetic systems. The upper ends of the left and right explosion-proof magnetic systems are connected together through the left and right upper connecting plates and bolts, and the lower ends are connected through the left and right lower connecting plates. It is a modular combined structure.

2. Product features:

a. High installation strength: The modular design of the double-pole iron remover ensures its installation strength, so that it can remain stable during use.

b. Convenient disassembly and assembly: Because of the bolt connection, the two explosion-proof magnetic systems are very convenient to disassemble and assemble, so that they can be used conveniently in places with limited space and load-bearing capacity.

c. Simple structure: The modular design is very convenient for the separate replacement of the explosion-proof magnetic system. Compared with the traditional fixed structure, the replacement is time-saving and labor-saving, which reduces labor intensity and improves work efficiency.

3. Working principle

The working principle of the double-pole iron remover is based on the combination of magnetic principle and physical principle. Its core component, the magnetic material, will generate a strong magnetic force in the magnetic field, which can attract and separate the iron impurities in the material. When the material flows through the iron remover, the iron impurities will be firmly adsorbed on the magnet by the magnetic force. With the movement of the magnet, the iron impurities are successfully separated, and the material continues to flow forward without any influence.

4. Application industry:

a. Power industry: used to remove iron impurities in coal and prevent boiler pipe blockage.

b. Mining industry: used for impurity removal and purification of ore to improve the grade of ore.

c. Metallurgical industry: used to remove iron impurities in the smelting process and improve product quality.

d. Garbage disposal: remove iron from garbage and recycle resources.

Flat plate iron remover

5. Product advantages:

a. Rapid iron removal: can quickly and accurately separate iron impurities in materials.

b. Protect equipment: prevent iron impurities from damaging production equipment and extend the service life of equipment.

c. Improve product quality: improve the purity and quality of products by removing iron impurities.

PS: Flat iron removers play an important role in modern industrial production with their characteristics of fast, stable and easy maintenance. Flat iron removers have broad development prospects and will provide more efficient and environmentally friendly iron removal solutions for industrial production. Flat iron removers will continue to develop in the direction of intelligence and automation to adapt to the continuous changes in the market and user needs. At the same time, enterprises also need to strengthen technology research and development and product innovation, and improve service quality to win market competition.

Save Time! Get A Detailed Quotation Quickly.