Flat plate magnetic separator is an important equipment widely used in garbage sorting, mineral processing, coal, chemical industry, food and other industries. Its main function is to separate magnetic substances in materials through the action of magnetic field. This article will introduce in detail the working principle, structural characteristics, high-frequency harmonic magnetic field flat plate magnetic separator and the advantages of gravity flat plate magnetic separator to help readers better understand and apply this equipment. In the past, plate conveyors only had the function of conveying materials and could not separate magnetic iron during the conveying process. Magnetic separator manufacturers have developed a device that can separate magnetic iron from materials in a simple conveying process, which is an energy-saving, consumption-saving and easy-to-use flat plate magnetic separator.

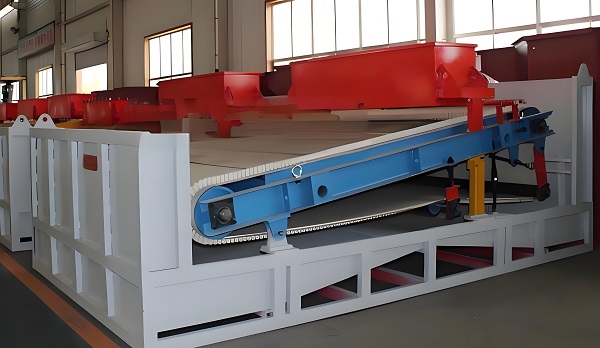

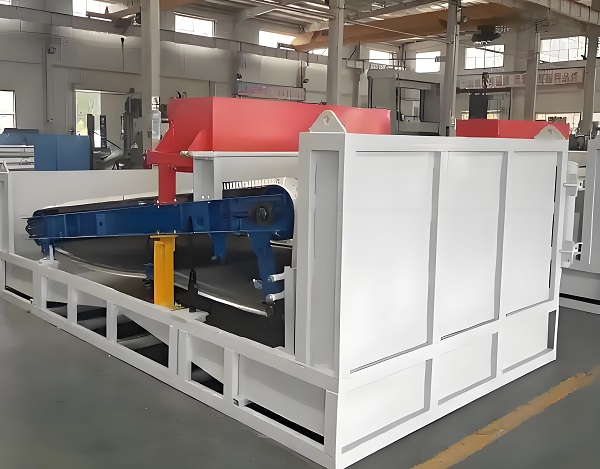

Flat plate magnetic separator

A. Advantages of flat plate magnetic separator:

1. Flat plate magnetic separator can make the falling ore evenly distributed on the magnetic separation mechanism without piling up into blocks. During the magnetic separation process, the ore can be turned over with the change of magnetic poles, greatly improving the accuracy of ore purification. Precision of material purification

2. Simple structure, easy to operate, the magnetic iron in the material can be separated during transportation, energy saving and consumption saving, especially for the waste resources of industrial ore separation.

3. Easy to manufacture, relatively cheap; less water and electricity consumption during operation, low cost of use.

4. Easy to operate, low failure rate.

5. Flat magnetic separator is particularly suitable for recovering weak magnetic minerals such as pyrrhotite and pyrite from iron and copper tailings, producing sulfur concentrate, and reducing tailings discharge, environmental pollution and land occupation by tailings, with great social and economic value.

Flat plate magnetic separator

B. Structure and working principle of flat magnetic separator

a. Structure of flat magnetic separator

The structure of flat magnetic separator includes frame, sprocket, chain plate, magnet, and magnetic roller. Sprocket and magnetic roller are installed at both ends of the frame, and the sprocket and magnetic roller are connected by chain plates. The magnet is fixed on the frame and corresponds to the inner side of the ring chain plate. A high-frequency vibrator is installed at intervals below the ring chain plate. It is mainly composed of magnetic separation mechanism, transmission mechanism and support mechanism. The magnetic separation mechanism is the core part of the flat magnetic separator, which includes components such as magnetic poles and fixed poles. The transmission mechanism is mainly composed of a motor and a reducer to drive the flat magnetic separator to operate. The support mechanism is mainly composed of a bracket and a support wheel to support the weight of the flat magnetic separator and maintain stability.

b. Working principle

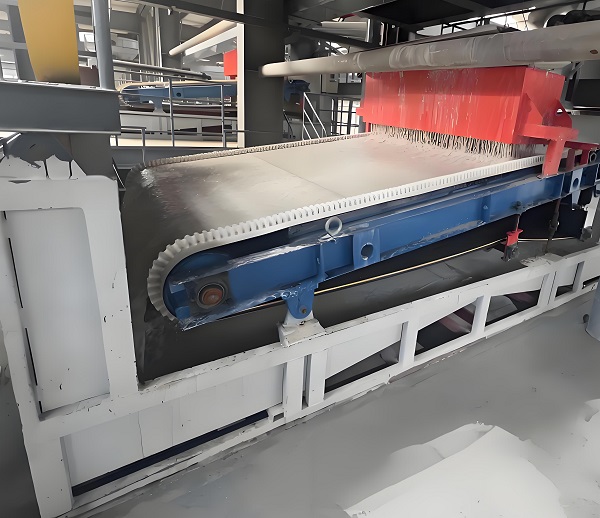

The material sizing device is located above the conveyor belt part between the lower side of the magnetic separation slope and the water supply system. The material sizing device includes upper and lower material sizing layers. Each material sizing layer includes a bottom with a drop mesh and a baffle plate arranged around the bottom. The drop mesh is evenly distributed at the bottom of the material sizing layer. The baffle plate is connected from head to tail to form a material receiving port. The aperture of the drop mesh corresponds to the size of the ore; Huabang Heavy Industry's water sizing device includes a spray pipe located above the magnetic separation slope and connected to the flushing water inlet pipe. A sprinkler with a uniform water hole at the bottom is provided directly below the spray pipe, and the spray pipe has several spray holes downward.

Flat plate magnetic separator

C. Features of high-frequency harmonic magnetic field flat plate magnetic separator:

The magnetic system of the high-frequency harmonic magnetic field separator is made of high-quality rare earth magnetic steel. The magnetic field strength of this machine is extremely high. It integrates physical mechanics, fluid mechanics, and magnetism. It can select certain weakly magnetic minerals from the ores according to the different magnetic properties of the ores. Wet processing of non-metallic ores for iron removal and purification, especially wet iron removal of non-metallic ores such as quartz sand and potassium-sodium feldspar. In addition, it has a good separation effect for weakly magnetic minerals such as limonite, hematite, siderite, and manganese ore.

The high-frequency harmonic magnetic field flat plate magnetic separator adopts a high-liquid level tank, a 360-degree high-frequency rotating magnetic system, a combined rinsing device and an unloading device. These unique designs bring better effects of refining and reducing impurities. Multiple parameters of the equipment can be adjusted, and it is more adaptable and can better meet the needs of users. Its advantages are as follows:

1. The separation principle is advanced. The magnetic system and the cylinder rotate asynchronously to form a high-frequency alternating magnetic field. The magnetic particles form loose needle-shaped short magnetic chains on the surface of the magnetic cylinder. Compared with the long magnetic chains tightly arranged in the ordinary magnetic system, it is easier to expose the inclusions of gangue or intergrowth. The number of tumbling times is more than that of conventional magnetic separators, with high separation efficiency and large product improvement.

2. The high liquid level tank structure is adopted to keep the magnetic chain on the cylinder surface shaking in the slurry, so that the gangue and intergrowth can be better separated.

3. The design of the magnetic field force in the sorting space is higher than that of ordinary magnetic separators, which can maintain the grade of tailings.

4. The cylinder of this flat magnetic separator adopts new non-metallic materials to avoid material loss, light weight and high strength.

5. The rotation speed of the cylinder and the magnetic system, the slurry level and other parameters are adjustable, and have good adaptability.

6. High-performance NdFeB magnetic materials are selected, and the magnetic circuit is uniquely designed. The surface magnetic field can reach 15000GS, which is comparable to high-gradient electromagnetic magnetic separators.

7. Compared with other permanent magnetic separators, the magnetic field sweeping area is large and the iron removal effect is good.

8. The plate surface slope is adjustable. Adjusting the slope according to the material condition can achieve a good iron removal effect.

9. The belt speed is variable and adjustable. Adjusting the belt speed according to the material condition can achieve a better iron removal effect.

10. Wear-resistant canvas is used as the conveyor belt, which greatly increases the service life of the conveyor belt.

11. Compared with other high-gradient vertical ring magnetic separators, it saves electricity and energy.

12. The ore is equipped with a uniform feeding device; the tailings are equipped with an automatic cleaning device for adsorbed magnetic materials.

Flat plate magnetic separator

D. Advantages of self-flowing flat plate magnetic separator:

1. The self-flowing flat plate magnetic separator is a magnetic separation equipment based on the action of a magnetic field. It is mainly composed of magnetic poles, magnetic conductive plates, slurry tanks, ore feeding devices and ore discharging devices. Its basic principle is to use the magnetic field force between the magnetic poles and the magnetic conductive plates to adsorb magnetic particles on the magnetic conductive plates and separate them from the slurry by gravity.

2. The self-flowing flat plate magnetic separator has a simple structure, convenient operation and low maintenance cost. Its main components include magnetic poles, magnetic plates, slurry tanks, feeding devices and discharging devices, among which magnetic poles and magnetic plates are key components. The magnetic poles are usually made of magnetic materials with high magnetic permeability and high remanence to ensure the magnetic field strength and separation effect; the magnetic plates are made of materials with good magnetic conductivity to ensure that the magnetic particles can be quickly adsorbed on their surface.

As an important magnetic separation equipment, the self-flowing flat plate magnetic separator has broad application prospects in industrial and laboratory applications. In the future, with the continuous promotion of market demand and technological progress, the self-flowing flat plate magnetic separator will usher in more development opportunities and challenges.

PS: As an important separation equipment, the flat plate magnetic separator has broad application prospects in mineral processing, coal, chemical industry, food and other industries. Through the introduction of the working principle, structural characteristics, application fields and maintenance of the flat plate magnetic separator, I believe that readers have a deeper understanding of this equipment.

Save Time! Get A Detailed Quotation Quickly.