Vibrating screen is a highly efficient screening equipment, which is widely used in many industries. The following is a detailed introduction to the vibrating screen:

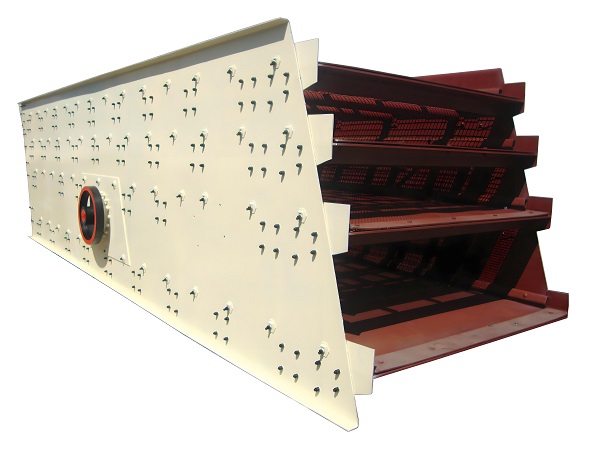

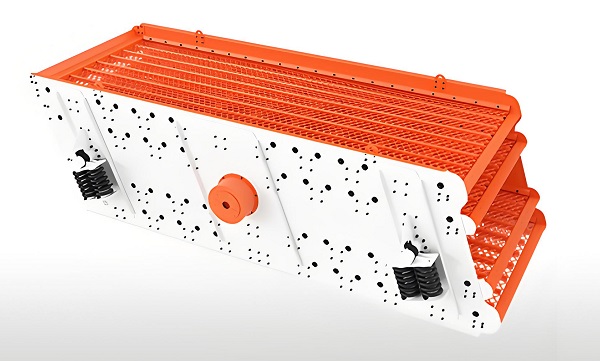

Vibrating screen

A. Definition and working principle of vibrating screen

1. Definition: Vibrating screen is a screening equipment that uses the principle of vibration to classify materials.

2. Working principle: The exciting force generated by the vibrating motor makes the screen body do reciprocating or circular motion, so that the material jumps on the screen surface and is classified according to the particle size. Specifically, the upward rotation and sagging of the vibrator causes the screen surface to produce a plane gyratory vibration, and the combined effect causes the screen surface to produce a negative transformation vibration, and its vibration trajectory is a complex spatial curve. The curve is projected as an ellipse on the horizontal plane and an ellipse on the vertical plane.

B. Main features of vibrating screen

Vibrating screen

1. High screening efficiency: The vibrating screen can quickly classify materials, especially suitable for the processing of large quantities of materials.

2. Flexible adjustment: The vibration frequency and amplitude can be adjusted as needed, and the screens of different specifications can be used to achieve accurate material classification.

3. Easy operation: The operation of the vibrating screen is relatively simple and easy to maintain and maintain.

C. Application industries of vibrating screens

Vibrating screen

1. Garbage screening industry: It can screen domestic garbage, construction waste, and urban solid waste.

2. Construction industry: It is used to screen building materials such as concrete, sand, and gravel to ensure the quality and uniformity of the materials and meet building standards and construction requirements.

3. Chemical industry: It is widely used in screening chemicals, coatings, paints, pigments, fertilizers, plastic particles, resins and other materials to ensure the quality and purity of the materials, meet the particle size requirements, and ensure product quality.

4. Pharmaceutical industry: It is used to screen materials such as medicines, vaccines, and syrups to ensure the quality and purity of medicines and meet the quality standards of medicine production.

5. Food processing industry: It is used to screen food raw materials such as flour, sugar, starch, milk powder, and salt to ensure the quality and uniformity of food raw materials and ensure the quality and safety of food.

6. Metallurgical industry: It is used for screening ore, slag, and mineral powder to optimize the metal refining process and improve smelting efficiency.

7. Environmental protection industry: It can be used in the treatment of wastewater, waste oil, etc. to help recycle and utilize resources and reduce environmental pollution.

8. Mining: used to screen materials such as ore, coal, limestone, etc., to ensure the quality and purity of the materials, while improving the utilization rate and processing efficiency of the ore.

Vibrating screen

D. Types and selection of vibrating screens

1. Types: There are many types of vibrating screens, such as rotary vibrating screens, three-dimensional vibrating screens, ultrasonic vibrating screens, etc. Each type has its specific application scenarios and advantages.

2. Selection: When selecting a vibrating screen, factors such as the nature of the material, screening requirements, and production environment need to be considered to ensure that the selected equipment can meet production needs.

E. Maintenance and care of vibrating screens

1.Regular inspection: Regularly check the wear of the vibration motor, screen, bearings and other components of the vibrating screen, and replace the seriously worn parts in time.

Specifications of Vibrating Screen:

| Model | Screen area | Installation angle | Throughput | Speed | Motor power |

| (m2) | (°) | (t/h) | (r/min) | (kw) | |

| 2ZCVC1860 | 21.6 | 20-24 | 150-250 | 760 | 18.5 |

| 2ZCVC2060 | 24 | 20-24 | 180-320 | 760 | 22 |

| 3ZCVC2060 | 32 | 20-24 | 250-380 | 760 | 22 |

| 2ZCVC2470 | 33.6 | 21-24 | 280-400 | 760-840 | 30 |

| 3ZCVC2470 | 50.4 | 21-24 | 320-450 | 760-840 | 30 |

| 2ZCVC3070 | 42 | 21-24 | 380-500 | 760-840 | 37 |

| 3ZCVC3070 | 63 | 21-24 | 450-520 | 760-840 | 37 |

| 2ZCVC3080 | 48 | 20-22 | 500-650 | 760-840 | 37x2 |

| 3ZCVC3080 | 72 | 20-22 | 550-700 | 760-840 | 37x2 |

2. Cleaning and maintenance: Regularly clean the screen and body of the vibrating screen to avoid material residues causing equipment blockage or damage.

3. Lubrication and maintenance: Regularly lubricate the bearings and other components of the vibrating screen to ensure smooth operation of the equipment.

PS: Vibrating screens have been widely used in many industries due to their high efficiency, multi-function and automation. By rationally selecting and maintaining vibrating screens, production efficiency and product quality can be significantly improved, making important contributions to the development of various industries.

Save Time! Get A Detailed Quotation Quickly.