The finger screen (polyblock finger screens)is a screening mechanical equipment commonly used for screening granular materials. It uses a group of bar steel bars or bar materials as screening elements, and divides the materials into different particle size grades through the rotation and vibration of the screening elements. The finger screen(polyblock finger screens)has the advantages of simple structure, convenient operation and maintenance, and good screening effect. Therefore, it is widely used in environmental protection, chemical, metallurgical, mining, building materials and other industries.

A. Advantages of finger screen:

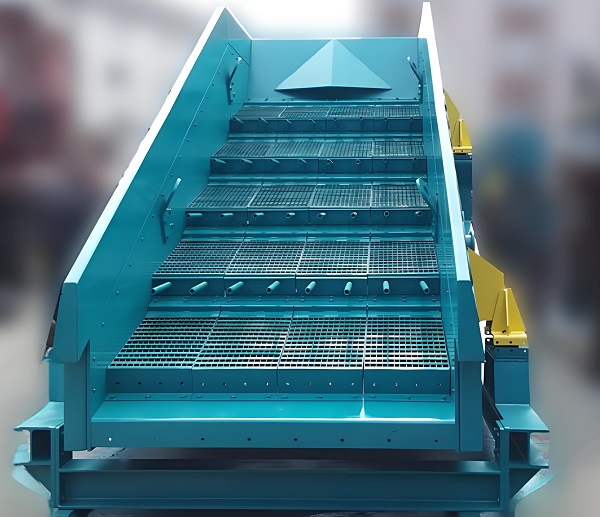

Finger Screen

1. High strength of the whole machine: The finger screen has a simple and compact structure, beautiful appearance, high rigidity and strength of each part; relatively small size and light weight, convenient for system process layout.

2. High screening efficiency: The finger screen has a relatively large processing capacity, low energy consumption and is not easy to block holes. The finger screen is especially suitable for screening materials with high moisture and high viscosity.

3. Wide range of applications: Suitable for coal, mining, metallurgy, building materials, electricity, water conservancy, light industry and chemical industries, for the classification of block and small and medium-sized particle materials.

4. Mature and perfect equipment: Combined with the application and extension in the mining and coal industries, its design is more mature and perfect, with strong excitation force, high screening efficiency, low noise, and economical use.

5. Full range of models and specifications: The finger screen has two structural forms, open and closed, suitable for different working environment requirements, single-layer and multi-layer screen surface structures, and running tracks in two forms of straight and circular.

6. Convenient installation: Convenient installation and debugging, stable and reliable operation, simple operation and maintenance; the finger screen power supply voltage is 380V and 660V. Please determine the voltage standard and whether there are explosion-proof requirements when selecting.

Finger Screen

B. Introduction to finger screens

Finger screens are mainly used in environmental protection, metallurgy, coke, coal, coal washing, chemical industry, building materials and hydropower engineering, abrasive waste treatment, quarrying and other industries for washing, screening, grading and other industries. The new structural model screen plate of various width specifications and mesh sizes of bar vibrating screens is especially suitable for occasions with strong impact, high hardness and high wear resistance. The bar vibrating screen is used for fine crushing and screening of iron ore, grading of raw coal, screening of gold, building materials, and sand and gravel for hydropower and nuclear power projects with wear-resistant screen plates.

The bar vibrating screen adopts a feeding surface in the form of blind plates and bars. The bar vibrating screen is suitable for uniform feeding of large pieces of materials before the crusher. The bar vibrating screen is particularly suitable for feeding black or non-ferrous metal ores and building stones before coarse or medium crushing. The bar gap of the bar vibrating screen is adjustable, which can separate the soil and fine materials while feeding, giving full play to the function of the crusher behind. The bar vibrating screen has the characteristics of simple structure, easy maintenance, high strength, impact resistance, wear resistance, and low noise.

The bar vibrating screen is used for uniform feeding and separation of bulk materials before the crusher. The bar vibrating screen is particularly suitable for feeding and preliminary screening before the coarse crushing of hydropower industry, building stones, ferrous or non-ferrous metals, and ores; the bar vibrating screen vibrating feeder uses a vibration motor as the excitation source, with a simple structure and convenient maintenance; large output, long life, strong and durable.

Finger Screen

C. Product structure of finger screen

The bar vibrating screen product is mainly composed of an excitation source (vibration motor), a body, a vibration damping spring, front and rear brackets, etc.

1. The finger screen vibration motor is a new type of exciter that integrates the power source and the vibration source into one, with high energy saving, large excitation force, reliable use, simple adjustment, and convenient use and maintenance.

2. Bar vibrating screen body: It is welded with plates and profiles, and its function is to transport the future material to the crusher through vibration.

3. Bar vibrating screen vibration damping spring: Generally, metal spiral springs or rubber springs are used, and its function is to generate elastic vibration in the body and reduce the vibration load transmitted to the foundation or structural frame.

4. Bar vibrating screen support: It is made of plate welded and its function is to support the machine body.

Finger Screen

D. Working principle of finger screen

When the finger screen is working, the exciting force generated by the exciter is transmitted to the screen surface in the screen box through the screen box. Because the exciting force generated by the exciter is a longitudinal force, the screen box is forced to drive the screen surface to move forward and backward longitudinally. Under certain conditions, the material on the screen surface of the bar vibrating screen is thrown forward due to the exciting force. When falling, the material smaller than the screen hole passes through the screen and falls to the lower layer. The movement trajectory of the bar vibrating screen material on the screen surface is parabolic motion. The finger screen completes the material screening operation due to such a repetitive material movement.

Finger Screen

E. Specifications of finger screen

1. Screen length and screen width: Screen length and screen width refer to the length and width of the finger screen, respectively. Generally, they are determined according to the material screening requirements and production capacity requirements. The screen length and screen width of different models of finger screens are also different.

2. Screen aperture: The screen aperture refers to the size of the finger screen, which is generally based on the actual screen aperture, and also takes into account the characteristics of the material itself and the particle size requirements that need to be classified.

3. Number of screen layers: The number of screen layers refers to the number of screening layers of the finger screen, which is generally determined according to the particle size distribution of the material and the screening requirements. Different materials require different numbers of screen layers when screening.

Finger Screen specification sheet:

| Model | Dimensions (mm) | Motor power (kw) | Number of layers | Processing capacity (t/h) | Amplitude (mm) | Vibration intensity | Installation inclination | Separation particle size (mm) | Maximum feed size (mm) |

| ZCFS1231 | 1200×3000 | 2×7.5 | 1 | 300-700 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 500 |

| ZCFS1242 | 1200×3900 | 2×11 | 2 | 300-700 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 500 |

| ZCFS1541 | 1500×3900 | 2×11 | 1 | 600-1100 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 700 |

| ZCFS1542 | 1500×3900 | 2×15 | 2 | 600-1100 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 700 |

| ZCFS1841 | 1800×3900 | 2×11 | 1 | 800-1300 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 900 |

| ZCFS1842 | 1800×3900 | 2×22 | 2 | 800-1300 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 900 |

| ZCFS2151 | 2100×4800 | 2×22 | 1 | 900-1500 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 1200 |

| ZCFS2451 | 2400×4800 | 2×30 | 1 | 1000-1800 | 5-14 | Maximum 4.5G | 5°-10° | 60-250 | 1500 |

PS: This article mainly introduces the advantages of finger screens(polyblock finger screens), product structure, various models and their parameter specifications, hoping to help readers better understand and choose finger screens that suit their needs. It should be noted that when choosing a finger screen(polyblock finger screens)that suits you, you need to consider it comprehensively based on the characteristics of the material itself and the production process requirements.

Save Time! Get A Detailed Quotation Quickly.