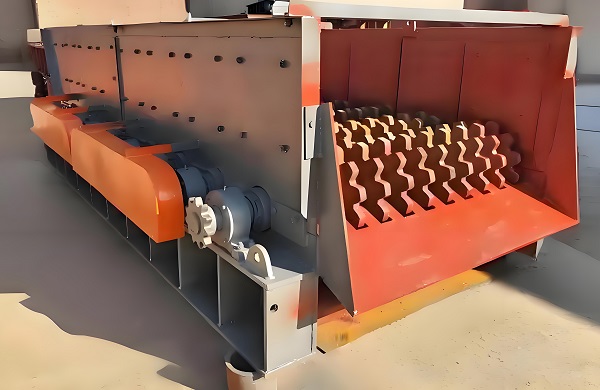

Mud and stone separator is an efficient separation equipment mainly used for separating materials such as garbage, mud and stone, sand and stone, and ore. It adopts advanced separation technology and uses a multi-stage linkage shaft driven by a motor to flip and separate materials in a jumping manner on the screen. The mud rock separator has the advantages of simple structure, easy operation, high separation efficiency, and wide applicability. It can separate various materials with different properties, such as solids and liquids, coarse and fine materials, etc. Mud and stone separator is an efficient and multifunctional mechanical equipment widely used in waste treatment, mining, construction, coal and other fields. Its core function is to effectively separate mixed materials such as mud, sand, and ore, improve material utilization, and reduce production costs. Meanwhile.

A. Introduction to Mud and Stone Separators

1. Overview of Mud and Stone Separators

Mud and stone separator is an efficient separation equipment, also known as multi-stage linked roller screen, soil and stone separation screen, roller screen, butterfly screen, etc. It is mainly used to separate various types of stone materials such as mud, sand, ore, as well as household waste, construction waste, industrial waste, coal, decoration waste, sticky wet materials, etc. Mud and stone separator is an efficient and multifunctional mechanical equipment widely used in various fields such as mining, construction, and coal. Its core function is to effectively separate mixed materials such as mud, sand, and ore, improve material utilization, and reduce production costs.

2. Working principle

The working principle of the mud and stone separator is based on advanced screening technology, which uses a motor to drive multi-stage linkage shafts for flipping motion, allowing materials to undergo jumping separation on the screen. This separation method is not only efficient, but also capable of handling materials of various properties, such as solids and liquids, coarse and fine materials, etc. At the same time, the compact structure, small footprint, and easy mobility and transportation of the mud and stone separator enable it to perform excellently in various complex environments.

3. Application Fields

Mud and stone separators are widely used for screening various raw materials. Their feeding methods are simple and diverse, and can be designed and conceptualized according to the real market needs of customers on site. Whether it is a funnel type, transmission chain type, or feeder type, they can be matched with production and processing manufacturing without the need to choose other special feeding methods.

4. Advantages and disadvantages

a. Advantages

① Efficient separation: By adopting advanced separation technology, a large amount of material separation can be completed in a short period of time, greatly improving production efficiency.

② Wide applicability: Suitable for separating materials of various properties, such as solids and liquids, coarse and fine materials, etc.

③ Easy to operate: The operation is simple and easy to understand, just press the corresponding button to complete the operation, reducing the labor intensity of workers.

④ Compact structure: adopting a compact design structure, occupying small space, and convenient for movement and transportation.

⑤ The mud and stone separator also has the advantages of easy operation and maintenance. Users only need to undergo simple training according to the operation manual to proficiently operate the device. At the same time, the maintenance of the equipment is relatively simple. Just regularly check the wear and tear of the equipment, replace worn parts in a timely manner, and ensure the long-term stable operation of the equipment.

b. Disadvantages

① High cost: Due to the use of advanced technology and materials, its manufacturing cost is relatively high.

② Maintenance difficulty: The internal structure is relatively complex, and maintenance requires professional personnel.

③ High noise: During operation, significant noise is generated, which has a certain impact on the surrounding environment.

④ Low accuracy: Although it can separate materials, its separation accuracy is relatively low, and the separation effect is not good for some fine materials.

5. Precautions for use

The equipment should be fixed on a dedicated foundation and secured with pre embedded bolts.

After installation, an air run inspection should be carried out to confirm that the motor rotates synchronously in reverse. If there is any abnormal noise during operation, the equipment should be quickly shut down for inspection and handling.

When screening materials, the materials should be evenly fed into the inlet to ensure even distribution on the screening surface.

When materials fall, there should be no significant impact to avoid damage.

Strictly follow the startup and shutdown steps for operation.

Regularly maintain and upkeep the equipment, including adding lubricating oil, checking the bearing seat screws, etc.

In summary, the mud rock separator is an efficient and widely used separation equipment, but it is also necessary to pay attention to its advantages and disadvantages as well as corresponding usage precautions during use.

B. The difference between mud and stone separator and butterfly sieve

Roller screen, also known as debris separator and butterfly screen. It is mainly composed of a disc and a shaft, which can be dispersed and screened through the rotation of the shaft. When the material runs in a lower direction, it is difficult to separate and clean materials such as particles, adhesive particles, stone, etc. due to the force matching the shape of the blade. Its working principle is that the motor drives the linked shaft, which has an irregular shape. The screen surface is composed of multiple linearly arranged rotating bearings, and there are identical screen plates on the rollers. The roller is driven by a gear chain to rotate, and the direction of rotation is consistent with the flow direction of the raw material. The irregular wear-resistant device embedded between the shafts supports the forward movement of large particle materials. Because the screen shaft is designed according to different running directions, the speed is faster when the material runs in the low direction; Due to the fact that the screen shaft is designed according to different operating directions, two different wear-resistant devices have been applied to the material on the screen bottom machine, allowing the material to be processed on the screen bottom machine.

When selecting equipment, you can choose to sieve first and then crush or crush first and then sieve based on the actual production situation. According to the particle size and hardness of the raw materials, different specifications and models can be selected for crushing. Jaw crusher, heavy hammer crusher, cone crusher, fine crusher, impact crusher, etc. When selecting equipment, it is possible to screen according to the actual production situation, or choose different specifications of models based on the particle size and hardness of raw materials. Jaw crushers, heavy hammer crushers, cone crushers, fine crushers, impact crushers, etc. can be freely developed. The mobile soil separator is precisely driven by the vehicle mounted tire device and can be mounted on the front of the car in the same form as a regular vehicle. In addition, with a modular assembly structure, it can be folded and extended, making it more convenient and efficient to move around.

The main classification of mud and rock separation and screening equipment is that, in simple terms, screening refers to the separation of different grades of loose materials through sieve holes and particle sizes. There are many classifications of screening equipment, most of which are widely used in industrial sectors such as mining and petrochemicals. They can generally be divided into five categories: pre screening and inspection screening, which refers to the particle size specification of the crushed material before crushing, mainly to detect whether the material meets the feeding size specification of the crusher, called pre screening. The material enters the crusher for crushing; For the particle size screening of crushed products, materials that do not meet the size specifications are called inspection screening. These two types of screening are collectively referred to as auxiliary screening in production and processing.

C. The performance characteristics of the mud and stone separator are also very obvious, mainly including the following features:

1. High screening accuracy, with a processing capacity four times that of traditional drum screens of the same volume. The quotation for butterfly screen is 1. The production capacity can reach up to 10000 times t/h.

2. The frequency converter drive method has low power, low energy consumption, stability, adjustable processing capacity, small size, does not take up space, and is easy to move.

3. The material is automatically discharged and can operate continuously. It can be transported, separated, screened, and other functions in different industries. The butterfly screen factory achieves multi use of one machine.

4. Wear resistant chain wheel, chain linkage, butterfly screen price, tension chain design, stable operation, mechanical firmness, low noise, few vulnerable parts, easy replacement.

5. Modular assembly can be lengthened or shortened according to material conditions, making it easy to maintain and adjust the structure.

6. High operational stability, wide screening range, suitable for various types of household waste, commercial/industrial waste, mud/sand/ore, decoration/construction waste, wet material separation, etc.

In short, the mud and stone separator is a high-performance and widely used separation equipment that provides strong support for the screening of various raw materials.

The mud and stone separator also has the characteristics of compact structure, small footprint, easy mobility and transportation. When using, attention should be paid to operating procedures to avoid excessive feeding or improper operation that may cause equipment damage or affect separation efficiency.

In addition, the mud rock separator also has the advantages of easy operation and convenient maintenance. Users only need to undergo simple training according to the operation manual to proficiently operate the device. At the same time, the maintenance of the equipment is relatively simple. Just regularly check the wear and tear of the equipment, replace worn parts in a timely manner, and ensure the long-term stable operation of the equipment.

Mud and stone separators play an important role in waste sorting, mining, construction, coal and other fields due to their high efficiency, multifunctionality, compact structure, and easy operation. With the continuous advancement of technology, the performance of the mud and stone separator will be further improved, providing more efficient and reliable support for the screening of various raw materials.

Save Time! Get A Detailed Quotation Quickly.