The finger screen is a highly efficient screening equipment. It has the characteristics of strength, impact resistance, wear resistance, and low noise. It is widely used in garbage disposal, mining, coal, metallurgy and other industries. It can achieve effective separation of materials and recycling of resources.

【Device Type】:Screening Machine

【Handling Materials】:Materials with uneven particle size and high water content, such as construction waste, ore, coal, coke, sand, gravel, garbage, etc..

【Equipment capacity】:5-300T/H

【Equipment power】:10-200W/H

【Scope of application】:Waste disposal, mining, coal, metallurgy and other industries

Finger screen are widely used in screening equipment in many industrial fields. They achieve effective separation and classification of materials through specific screen surface structures and working principles. It is an efficient and precise screening equipment with a wide range of application fields and significant advantages. Through regular maintenance and upkeep, the normal operation and service life of the finger screen can be ensured, providing strong support for industrial production.

Finger Screen

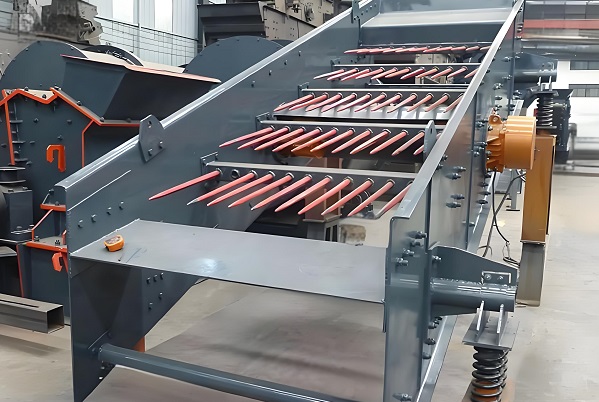

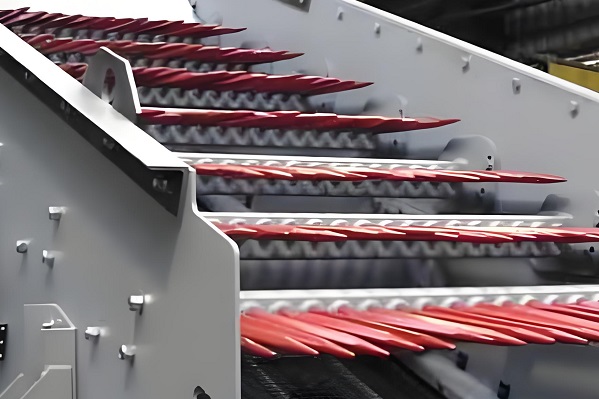

The finger screen can be used in the pretreatment (rough sorting) of decoration waste, stale waste, and domestic waste, and can also be used in sand and gravel production lines to separate mud and gravel. Double exciter finger screen, screen hole size 100mm, materials larger than 100mm enter the manual sorting platform, materials smaller than 100mm enter the drum screen for the next step of fine screening; the upper screen can be adjusted according to the properties of the material. The gap between its rods is adjustable, and it can separate the soil and fine materials while feeding, effectively exerting the functions of the subsequent equipment; it has the characteristics of simple structure, easy maintenance, high strength, impact resistance, wear resistance, and low noise. .

The finger screen can handle various materials with uneven particle size and high water content, such as construction waste, ore, coal, coke, sand and gravel, garbage, etc. It is an important equipment for material classification, impurity removal, desliming and other processes. .

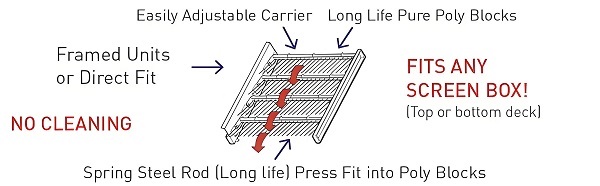

The screen surface of the finger screen consists of a series of rods arranged in parallel. The gaps between these rods can be adjusted as needed to adapt to the screening requirements of different materials. When the material enters the finger screen, the particles smaller than the screen hole size will fall through the screen hole, while the particles larger than the screen hole size will move forward along the screen surface and finally be discharged from the end of the screen surface.

Rod vibrating screen has new structural model screen plates with various format specifications and screen hole sizes, which are especially suitable for occasions with strong impact, high hardness and high wear resistance. Rod vibrating screens are used for fine crushing and screening of iron ore, classification of raw coal, gold, building materials, and screening of sand and gravel in hydropower and nuclear power projects. Wear-resistant screen plates.

Finger Screen

The rod vibrating screen product adopts a feeding surface in the form of blind plates and rods. The rod vibrating screen is suitable for uniform feeding of large materials in front of the crusher. The rod vibrating screen is especially suitable for black or non-ferrous metal ores, It is used for feeding building stones before coarse or medium crushing; the rod-type vibrating screen has adjustable rod gaps, which can separate soil and fine materials while feeding, giving full play to the function of the subsequent crusher; rod-type vibrating screen It has the characteristics of simple structure, easy maintenance, high strength, impact resistance, wear resistance, and low noise.

The finger screen is a device that uses a screen surface composed of rods to separate materials. The screen surface is composed of a series of rods arranged in parallel. These rods can be made of different materials such as manganese steel, guide rails, stainless steel, etc. to adapt to different working environments and material characteristics. The structure of the finger screen is relatively simple, but its function is powerful. It is an indispensable equipment in many industrial fields.

finger screen is a screening equipment specially used to handle various bulk materials. It can effectively separate materials according to particle size and is widely used in many industries such as environmental protection, mining, coal, metallurgy, building materials, chemical industry, water conservancy, electric power, light industry and transportation.

The finger screen is a screening device widely used in the fields of mining, building materials, metallurgy, decoration, construction waste treatment and garbage classification. Its structure and working principle are as follows:

1. Basic structure and components of the finger screen

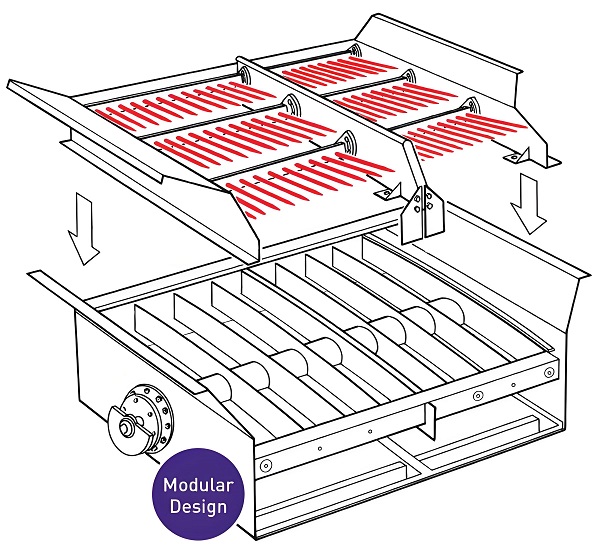

The finger screen is mainly composed of key components such as the screen box, drive device, support structure and screen surface composed of multiple parallel bars. The screen box is the main structure that accommodates the finger screen surface, the drive device is responsible for providing the vibration or rotation power required for screening, and the support structure ensures the stability and durability of the entire equipment.

Working principle of finger screen

2. Working principle of the finger screen

The working principle of the finger screen is mainly based on the physical properties of the material, especially the size, shape and weight of the material. When the materials are fed into the finger screen, they will be subjected to the force of vibration or rotation on the screen surface, so that they move on the screen surface. The following are the detailed steps of the working principle of the finger screen:

a. Material enters the screen surface: The material is fed into the screen box through the feed port and falls on the screen surface composed of bars.

b. Vibration or rotation: The drive device is started to drive the screen box and the screen surface to vibrate or rotate. This movement causes the material to tumble, jump and move on the screen surface.

Working principle of finger screen

c. Layered processing: Since the bars are installed in parallel, the movement of the material on the screen surface causes it to be layered according to the particle size. Smaller particles will fall through the gaps between the bars, while larger particles will remain on the screen surface and continue to move forward.

d. Screening of mesh size: Materials smaller than the mesh size will fall smoothly and be collected in the under-screen part when passing through the gaps between the bars. Materials larger than the mesh size will be retained on the screen surface and continue to be subjected to vibration or rotation until they are discharged from the screen surface.

e. Material discharge: After screening, materials of different particle sizes are collected on the upper and lower parts of the screen respectively. The upper part of the screen mainly collects larger particles, while the lower part of the screen collects smaller particles. These materials can then be sent out of the equipment through the discharge port for subsequent processing or utilization.

PS: The finger screen plays an indispensable role in various screening applications with its unique working principle, key characteristics and advantages, as well as a wide range of application scenarios and importance.

As an efficient and reliable screening equipment, finger screen plays an important role in many industries. The following are the main application areas of finger screen:

1. Construction waste treatment

On construction sites, a large amount of construction waste such as abandoned concrete blocks and bricks needs to be screened and processed. finger screen can efficiently remove impurities from these wastes, separate the useful materials from them, and improve the utilization rate of recycled materials. This not only helps to reduce the pollution of construction waste to the environment, but also realizes the recycling of resources.

Finger Screen

2. Mining field

Finger screen has a wide range of applications in the mining field, especially in the screening and grading of ores. Through its high-frequency vibration, finger screen can effectively separate ores of different particle sizes, thereby improving the efficiency of mineral processing and the utilization rate of ores. Before the coarse or medium crushing of ferrous or non-ferrous metal ores and building stones, finger screen is often used as a feeding device. The gap between its bars is adjustable, which can separate the soil and fine materials while feeding, effectively playing the role of the subsequent crusher.

3. Coal industry

During the process of coal mining and processing, a large amount of coal gangue and impurities will be generated. The finger screen can efficiently screen out fine coal and large pieces of coal gangue, improving the quality of coal combustion. At the same time, it can also classify coal according to particle size to meet different combustion needs.

4. Metallurgical industry

In the process of metallurgical production, the processing of raw materials is also inseparable from screening equipment. The application of finger screens in the metallurgical industry can significantly improve production efficiency and product quality. For example, in the screening process of raw materials such as iron ore, limestone, fluorite, cooling blast furnace slag, coke, etc., finger screens play an important role.

5. Waste treatment field

The finger screen is also widely used in waste treatment. It can effectively separate organic matter, paper, plastic, metal, etc. in urban domestic waste, which is convenient for subsequent treatment and recycling. At the same time, it can also be used to treat stale garbage, food processing waste, etc. to achieve resource recycling.

6. Chemical and food processing industries

In the production process of chemical products, finger screens are mainly used for fine screening of powder materials to ensure product quality and the smooth progress of subsequent production processes. In the food processing industry, finger screens are used to screen out unqualified or impure raw materials to ensure food safety. At the same time, it can also grade foods of different particle sizes according to demand.

7. Other fields

In addition to the above fields, finger screens are also widely used in agricultural fields for cleaning and grading of agricultural products (such as grains, seeds, etc.), as well as screening of sand and gravel in hydropower and nuclear power projects.

PS: finger screens play an important role in many industries with their efficient and reliable screening capabilities. It can not only improve screening efficiency, reduce labor costs and energy consumption, but also realize the recycling of resources, and contribute to sustainable development and environmental protection goals.

As an efficient and energy-saving screening equipment, finger screen plays an important role in many fields, especially in solid waste treatment. The following is a detailed analysis of the characteristics and advantages of finger screen:

A. Characteristics of finger screen

Finger Screen

1. Structural design and material

a. The design of finger screen adopts a feeding surface in the form of blind plate plus bar, which makes the screening process more efficient. The bar itself can be made of different materials such as manganese steel bar, guide rail, stainless steel bar, etc. The selection of these materials makes the finger screen have the characteristics of high strength, impact resistance and wear resistance.

b. The screen surface structure of finger screen is usually arranged in a stepped shape. Such a design not only improves the opening rate, speeds up the material flow rate, and makes the material layer thinner, but also helps to solve the problems of hole blocking and winding.

2. Excitation and screening principle

a. The finger screen is screened by the excitation force generated by the exciter. This excitation force forces the screen box to drive the screen surface to move forward and backward longitudinally, so that the material on the screen is thrown forward due to the excitation force, and the material smaller than the screen hole falls through the screen and falls to the lower layer when falling. This screening principle makes the finger screen have significant advantages in processing high-moisture and high-viscosity materials.

b. The screening process of the finger screen is stable and reliable, with high screening efficiency and not easy to block holes.

Finger Screen

3. Modularity and adjustability

a. The screen surface structure and type of the finger screen adopt modular design, which makes it more convenient to replace the screen surface, and the appropriate screen surface can be selected according to different operation needs.

b. The bar gap of the finger screen is adjustable, which makes the finger screen more flexible when processing materials of different particle sizes and properties.

B. Advantages of finger screen

1. High efficiency and energy saving

a. The finger screen adopts advanced screening principles and technologies to make the screening process more efficient. At the same time, due to its compact structure, small size and light weight, the processing capacity per unit equipment volume and weight is greater, thus achieving energy saving.

b. The exciter of the finger screen is reasonably designed, with strong excitation force, but relatively low energy consumption, which makes the finger screen more economical during operation.

2. Stable and reliable operation

a. The structure of the finger screen is simple and compact, and the rigidity of the whole machine and the strength of each part are large, which makes it more stable and reliable during operation.

b. The finger screen is easy to install and debug, and the operation and maintenance are simple, which reduces the maintenance cost and time.

Finger Screen

3. Wide range of applications

a. The finger screen is not only suitable for the treatment of stale domestic garbage, but also widely used for feeding before coarse or medium crushing of ferrous or non-ferrous metal ores and building stones. In addition, the finger screen also plays an important role in the washing, screening, and grading of materials in industries such as metallurgy, coke, coal, coal washing, chemicals, building materials, and hydropower engineering.

b. The finger screen has high screening efficiency, large processing capacity, and is not easy to block holes, which makes it have significant advantages in processing high-moisture and high-viscosity materials.

4. Environmental protection and sustainability

a. The finger screen can reduce the emission of dust and gas during the screening process, improve the working environment, and reduce secondary pollution to the environment.

b. The adjustability and modular design of the finger screen enable it to be adjusted and optimized according to different operational needs, thereby achieving more refined and personalized garbage sorting and processing.

PS: The finger screen has been widely used in many fields with its unique characteristics and significant advantages. With the continuous advancement of technology and the increasing requirements for environmental protection, the application prospects of the finger screen will be broader.

Author's note: Choosing the right finger screen is important for improving screening efficiency, reducing energy consumption, and improving production efficiency. Here are some suggestions on how to choose the right finger screen:

A. Clarify screening needs

Finger Screen

1. Understand material properties

a. The particle size, shape, humidity and other characteristics of the material are crucial to the selection of finger screens. Materials with larger particle sizes may require larger finger screens, while fine screening may require smaller finger screens.

b. Materials with higher humidity may cause sieve holes to clog, so it is necessary to choose finger screens with anti-clogging hole design.

2. Determine the purpose of screening: Determine the required screening accuracy and screening efficiency based on the purpose of the material after screening. For example, finger screens used in the chemical industry may require higher screening accuracy.

3. Evaluate the processing capacity of the finger screen: According to production needs, evaluate the required processing volume to select the appropriate finger screen model and specifications.

B. Examine the performance of the finger screen

Finger Screen

1. Screen box size and screen mesh specifications: The size of the screen box determines the processing capacity of the equipment, while the screen mesh specifications determine the screening accuracy. Therefore, when choosing a finger screen, you should choose the appropriate screen box size and screen specifications according to actual needs.

2. Bar material and size

a. The material of the bar directly affects the durability and use effect of the equipment. High-quality stainless steel has high corrosion resistance and tensile strength, and is an ideal choice for finger screens.

b. The size of the bar should be comprehensively considered according to the nature of the material and the processing volume. Generally speaking, larger bar diameters can be selected for materials with larger particle sizes, while smaller bar diameters should be selected for materials with smaller particle sizes.

3. Power source and energy consumption: finger screens are usually driven by electric motors or hydraulic motors. When choosing, you should choose a suitable power source according to actual needs and pay attention to the energy consumption of the equipment.

C. Consider the actual application scenario

1. Fixed site and mobile equipment: According to the actual situation of the work site, choose a finger screen suitable for fixed site use or equipped on a mobile device.

2. Noise and vibration control: When choosing a finger screen, you should pay attention to the noise and vibration of the equipment to ensure that it meets environmental protection requirements and safety production standards.

D. Comprehensive evaluation and selection

1. Refer to industry standards: Select finger screens that meet industry standards and specifications to ensure the safety and stability of the equipment.

2. Investigate the strength of the manufacturer: Select manufacturers with rich production experience and good market reputation to ensure the quality of the equipment and after-sales service.

3. Cost-effectiveness analysis: Under the premise of meeting the screening needs, comprehensively consider the price, performance, durability and other factors of the equipment, and select a finger screen with high cost performance.

PS: Choosing a suitable finger screen requires comprehensive consideration of multiple factors such as material properties, screening purpose, processing capacity, equipment performance and actual application scenarios. Through comprehensive evaluation and selection, it can be ensured that the selected finger screen can meet production needs, improve screening efficiency, reduce energy consumption, and improve production efficiency.

| Model | Single layer area (m²) | Number of layers (s) | Equipment inclination (°) | Particle size range (mm) | Power (kW) | Production capacity (t/h) |

| ZCFS1548 | 7.2 | 2 | 15~20 | 10~200 | 18.5 | ≤150 |

| ZCFS1848 | 8.6 | 2 | 15~20 | 10~200 | 22 | ≤180 |

| ZCFS2160 | 12.6 | 2 | 15~25 | 10~300 | 30 | ≤220 |

| ZCFS2460 | 14.4 | 2 | 15~25 | 10~300 | 37 | ≤260 |

| ZCFS1030 | 3 | 1 | 15~20 | 10~100 | 2×3.0 | ≤30 |

| ZCFS1236 | 4.3 | 1 | 15~20 | 10~150 | 2×3.0 | ≤50 |

| ZCFS1536 | 5.4 | 1 | 15~20 | 10~200 | 2×3.7 | ≤80 |

| ZCFS1836 | 6.5 | 1 | 15~20 | 10~350 | 2×5.5 | ≤120 |

| ZCFS1852 | 9.3 | 1 | 15~25 | 10~350 | 2×11 | ≤200 |

| ZCFS2160 | 12.6 | 1 | 15~25 | 10~500 | 2×15 | ≤250 |

| ZCFS2460 | 14.4 | 1 | 15~25 | 10~500 | 2×18.5 | ≤250 |

2025-01-03

2025-01-03

2025-01-03

2025-01-03

2024-12-05

2024-12-05

2024-12-03

2024-12-03

2024-11-14

2024-11-14

2024-11-05

2024-11-05

2024-11-05

2024-11-05

2024-11-01

2024-11-01Save Time! Get A Detailed Quotation Quickly.