In today's world where environmental protection is increasingly valued, garbage classification has become a global issue. Effective garbage classification can not only reduce environmental pollution, but also improve the recycling and utilization rate of resources. In this context, finger screens as an efficient garbage sorting device, its precise classification ability has brought revolutionary changes to garbage disposal.Finger screens Applicable materials: Suitable for screening urban garbage, mining coal, stones and other materials.

A. Application of finger screens in garbage disposal

Finger screens The application in garbage disposal is very extensive, including but not limited to the following aspects:

Urban household waste sorting: finger screens can effectively separate organic matter, paper, plastic, metal, etc. from household waste for subsequent processing and recycling.

Construction waste disposal: In construction waste, finger screens can be used to separate materials such as concrete blocks, bricks, wood, etc.

Food processing industry: In the food processing process, finger screens can be used to screen raw materials or products and remove non-conforming products.

B. What is finger screens?

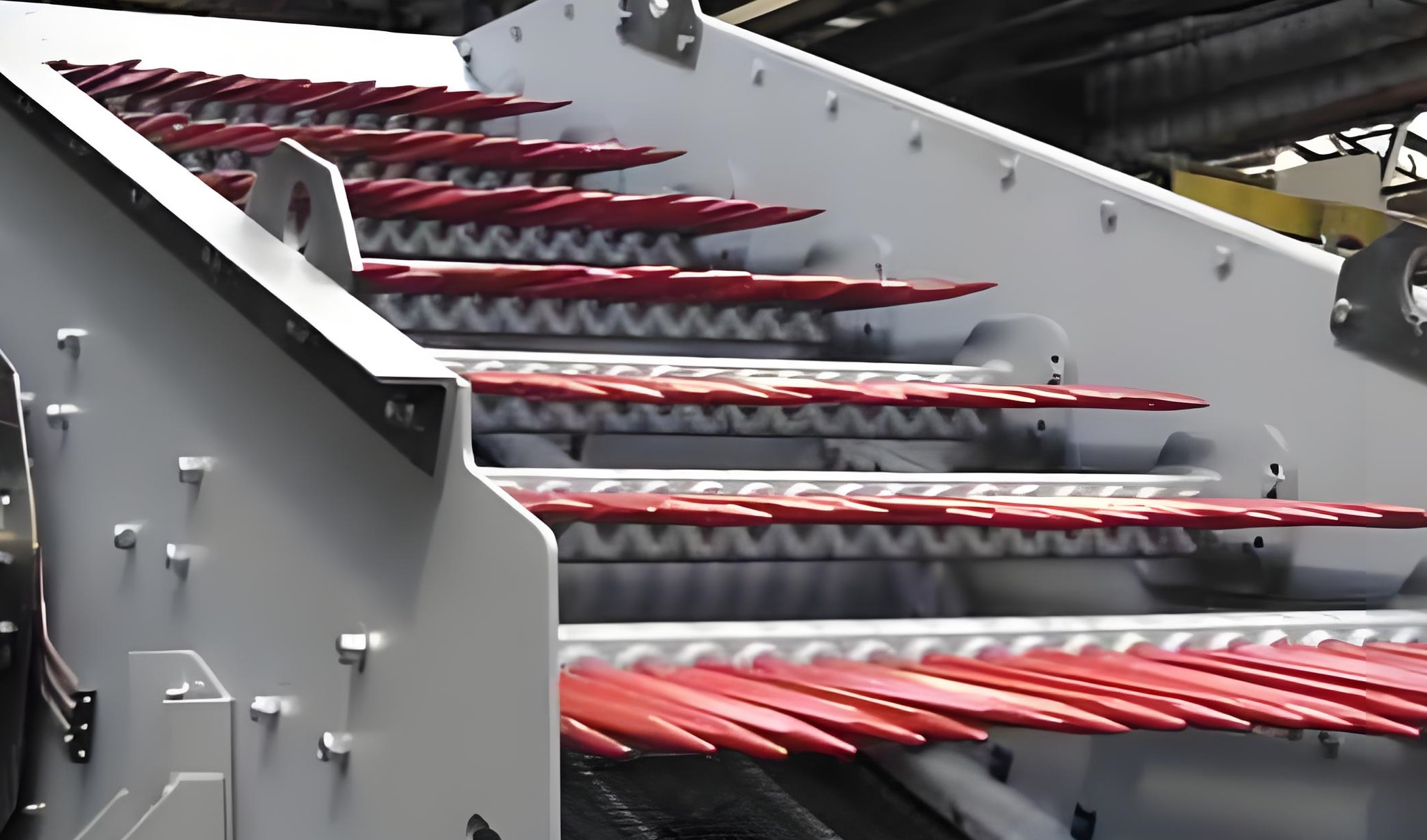

finger screensMainly used in industries such as garbage sorting, metallurgy, mining, and building materials screening, ore washing, and grading. A new structural pattern sieve plate with various sizes and mesh sizes of rod vibrating screens, especially suitable for applications with strong impact, high hardness, and high wear resistance requirements.

The bar type vibrating screen product adopts a feeding surface in the form of blind plates and bars. The bar type vibrating screen is suitable for uniform feeding of large blocks of materials in front of the crusher, and is particularly suitable for feeding garbage, black or non-ferrous metal ores, and construction stone before coarse or medium crushing; The gap between the bars of the bar type vibrating screen is adjustable, which can separate soil and fine materials while feeding, and play the role of a crusher in the later stage; Rod type vibrating screen has the characteristics of simple structure, easy maintenance, high strength, impact resistance, wear resistance, and low noise.

Rod type vibrating screen is used for uniform feeding and separation of large materials in front of crushers. Rod type vibrating screen is particularly suitable for the garbage screening industry, construction stone materials, black or non-ferrous metals, and ore coarse crushing before feeding and initial screening; The rod type vibrating screen vibrating feeder adopts a vibration motor as the excitation source, with a simple structure and easy maintenance; High yield, long lifespan, sturdy and durablefinger screens It is a device that uses screening surfaces composed of bars of different sizes to achieve sorting based on the size, shape, and weight of materials. It usually consists of a frame, driving device, screening rod, and cleaning systemfinger screens The design enables it to adapt to various complex material conditions, thus playing a crucial role in waste disposal.

C. How to achieve precise classification?

finger screensThe working principle is based on the physical properties of the material. When garbage passes through finger screens, small particles smaller than the gap between the bars will fall, while materials larger than the gap will be intercepted. This process can be optimized by adjusting the spacing, angle, and vibration frequency of the bars to meet different types of garbage sorting needs.

Adjustable gap: According to the requirements of garbage classification, the gap of finger screens can be adjusted to achieve effective screening of garbage of different sizes.

finger screensDuring operation, the excitation force generated by the exciter is transmitted to the screen surface inside the screen box through the screen box. As the excitation force generated by the exciter is a longitudinal force, it forces the screen box to drive the screen surface to undergo longitudinal forward and backward displacement. Under certain conditions, the material on the sieve surface of the rod vibrating screen is thrown forward by the excitation force. When the material falls below the sieve hole, it passes through the screen and falls to the lower layer. The motion trajectory of the material on the sieve surface of the rod vibrating screen is a parabolic motion. Due to the repeated motion of the material, the material screening operation is completed.

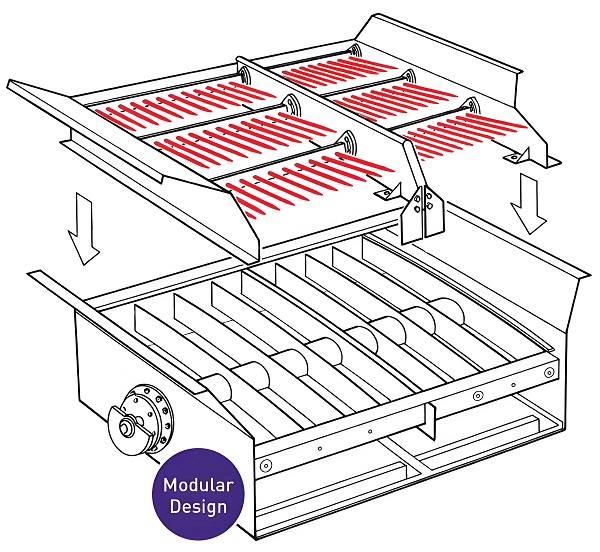

finger screensProduct structure: The bar type vibrating screen product is mainly composed of an excitation source (vibration motor), a body, a damping spring, front and rear brackets, etc.

1. finger screens Vibration motor is a new type of exciter that integrates power source and vibration source, with high energy saving, large excitation force, reliable use, and simple adjustment; Features such as easy use and maintenance.

2. Rod type vibrating screen body: made of welded plates and profiles, its function is to transport the material to the crusher through vibration.

3. Rod type vibrating screen damping spring: Generally, metal coil spring or rubber spring is used, which is used to generate elastic vibration of the machine body and reduce the transmission of vibration load to the foundation or structural frame.

4. Rod type vibrating screen bracket: made of welded plates, its function is to support the machine body.

Zhongcheng Machinery Production finger screens Features:

1. Multi level screening: By setting multiple screening layers, finger screens can divide garbage into multiple levels at once, improving sorting efficiency.

2. Automatic cleaning: finger screens The equipped cleaning system can automatically remove debris attached to the rod, ensuring that the screening effect is not affected.

3. Efficient transmission: With appropriate driving devices, finger screens can ensure even distribution of garbage on the screen surface and improve screening accuracy.

4. High overall strength: The structure is simple, compact, aesthetically pleasing, and the overall rigidity and strength of each part are high; Relatively small in size and light in weight, convenient for system process layout.

5. High screening efficiency: It has a relatively large processing capacity, low energy consumption, and is not easily clogged, especially suitable for screening materials with high moisture content and high viscosity.

6. Wide application range: Suitable for industries such as garbage sorting, mining, and building materials, for the classification and treatment of block shaped and small particle materials.

7. Mature and complete equipment: Combined with its application and extension in the garbage sorting industry, its design is more mature and complete, with strong excitation force, high screening efficiency, low noise, and economical use.

8. Full range of models and specifications: finger screens comes in two structural forms: open and closed, suitable for different operating environment requirements. The screen surface has single-layer and multi-layer structural forms, and the operating trajectory has two forms: straight and circular. There are various models and specifications.

9. Easy installation: Easy to install and debug, stable and reliable operation, easy operation and maintenancefinger screens There are two types of power supply voltage: 380V and 660V. When selecting, please confirm the voltage system and whether there are explosion-proof requirements.

| model | Single layer area (m ²) | Number of layers (s) | Equipment inclination angle (°) | Particle size range (mm) | Power (kW) | Capacity (t/h) |

| LBT1548 | seven point two | two | 15~20 | 10~200 | eighteen point five | ≤150 |

| LBT1848 | eight point six | two | 15~20 | 10~200 | twenty-two | ≤180 |

| LBT2160 | twelve point six | two | 15~25 | 10~300 | thirty | ≤220 |

| LBT2460 | fourteen point four | two | 15~25 | 10~300 | thirty-seven | ≤260 |

| BTS1030 | three | one | 15~20 | 10~100 | 2×3.0 | ≤30 |

| BTS1236 | four point three | one | 15~20 | 10~150 | 2×3.0 | ≤50 |

| BTS1536 | five point four | one | 15~20 | 10~200 | 2×3.7 | ≤80 |

| BTS1836 | six point five | one | 15~20 | 10~350 | 2×5.5 | ≤120 |

| BTS1852 | nine point three | one | 15~25 | 10~350 | 2×11 | ≤200 |

| BTS2160 | twelve point six | one | 15~25 | 10~500 | 2×15 | ≤250 |

| BTS2460 | fourteen point four | one | 15~25 | 10~500 | 2×18.5 | ≤250 |

Finger screens with its efficient and precise classification ability, it is playing an increasingly important role in the field of garbage disposal. It not only improves the efficiency of garbage classification, but also provides possibilities for the recycling of resources, making it an important tool for achieving sustainable development and environmental protection goals. With the continuous advancement of technology, the application of finger screens will become more widespread, bringing more convenience and environmental benefits to our lives.

Save Time! Get A Detailed Quotation Quickly.