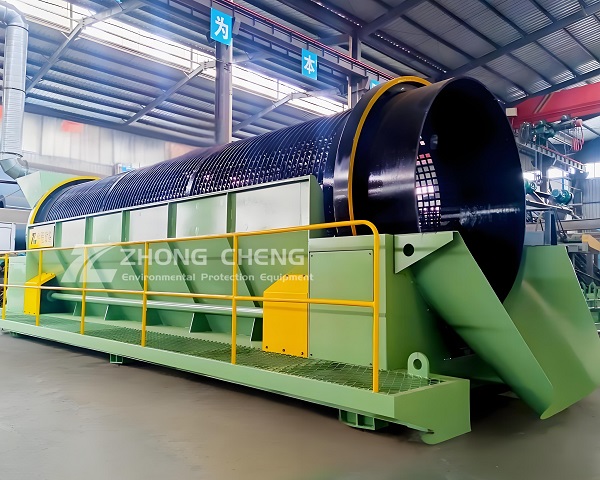

As core grading equipment in solid waste treatment, mine sorting, agricultural processing, and other fields, the trommel screen's screening efficiency, material compatibility, and operational and maintenance costs directly determine production profitability. Zhongcheng's trommel screen, with its innovative structure, application-specific customization, intelligent upgrades, and comprehensive service, overcomes the pain points of traditional equipment—frequent blockages, short lifespan, and poor adaptability—making it the preferred choice for customers across various industries. The following analyzes the core value of choosing Zhongcheng's trommel screen from four perspectives: technical strength, application-specific adaptability, economical operational and maintenance, and guaranteed service.

1.Structural and Technological Innovation: Breaking Through Bottlenecks in Screening Efficiency and Stability

Zhongcheng's trommel screen's core competitiveness stems from its iterative upgrades to the traditional structure. Through material optimization and functional integration, it achieves both enhanced screening efficiency and improved equipment lifespan.

The anti-clogging and wear-resistant structural design directly addresses industry pain points. To address the problem of screen clogging caused by sticky and fibrous materials, Zhongcheng utilizes a combined "comb-type cleaning + bidirectional rotation" technology. Flexible comb teeth built into the drum automatically clean the screen holes as the drum rotates. This alternating operation, with forward rotation compacting the material and reverse rotation fluidizing and removing impurities, reduces screen clogging by over 90%. The screen utilizes a composite structure of high-manganese steel and stainless steel with rounded edges. This not only resists the impact and abrasion of rocks in construction waste but also meets the corrosion resistance requirements of the food industry, extending its service life by 2-3 times compared to conventional screens. For example, when processing materials containing fruit acids, such as mango peels and pits, the 304 stainless steel screen prevents corrosion and rust. Its precise 5-8mm aperture design achieves an impurity separation rate of over 95%.

Variable frequency speed regulation and a multi-layer grading system enhance adaptability and precision. The equipment is equipped with a variable-frequency motor, offering stepless speed adjustment between 5 and 30 rpm, precisely tailored to the specific material characteristics. When screening construction waste, the speed is adjusted to 15-20 rpm to ensure adequate separation of concrete blocks and brick and tile fragments; when processing grains, the speed is reduced to 8-12 rpm to prevent grain damage. The multi-layer screen design supports simultaneous 2-4 levels of classification. For example, in mine tailings processing, the upper layer with 20mm apertures separates large impurities, the middle layer with 8mm apertures selects qualified mineral fines, and the lower layer with 3mm apertures collects fine mud. This single device can perform the classification tasks of traditional multiple machines in series, increasing efficiency by 40%.

The sealing and environmental performance meet stringent standards. The fully enclosed housing and flexible sealing strips, combined with a negative pressure dust collection device, keep dust concentrations below 5mg/m³ when conveying dusty materials such as fly ash and cement powder, complying with the "Comprehensive Emission Standards for Air Pollutants." The inner casing is sprayed with a polytetrafluoroethylene (PTFE) anti-stick coating, resulting in less than 1% residue when handling sticky materials such as food waste and livestock manure. It also facilitates high-pressure cleaning, preventing odor and cross-contamination.

2. Adaptability to All Industry Scenarios: Customized Solutions Meet Diverse Needs

Zhongcheng's drum screen, with its modular design, offers tailored solutions tailored to the material characteristics of diverse applications, such as environmental protection, mining, and agriculture. Its adaptability far exceeds that of general-purpose equipment.

Zhongcheng's shaftless drum screen has demonstrated outstanding performance in the field of environmental solid waste treatment. In construction waste recycling projects, the Zhongcheng shaftless drum screen can process mixed materials with concrete blocks and rebar up to 300mm in diameter. Its centerless design prevents rebar entanglement, and its wear-resistant lining provides resistance to impact from hard objects. Its daily processing capacity can reach 500t/h. For example, after adopting this equipment at Changzhou Lvhe Company, its efficiency in sorting construction waste has increased by 50% compared to traditional equipment. In the pre-treatment stage of waste incineration, high-temperature-resistant models (capable of withstanding 350°C) can directly screen crushed raw waste, separating lightweight combustibles like plastics and paper from heavier inorganic materials, providing homogenous raw materials for subsequent incineration. For food waste processing, the equipment is equipped with a hot air drying module (50-60°C) to reduce material viscosity, and an anti-stick screen effectively separates oil residue from wastewater.

It is suitable for high-wear conditions in the mining and construction sectors. For metal mine tailings processing, the Zhongcheng drum screen utilizes a high-chromium alloy screen (hardness above HRC58) to withstand the erosion of fine particles in the slurry and has a continuous operating life of over 8,000 hours. The tilted mounting design (maximum angle of 30°) allows for direct connection to the sedimentation tank and dewatering screen, eliminating the need for additional lifting equipment and saving 30% on site costs. During shield tunneling, compact shaftless drum screens fit into tight spaces and can screen shield soil with a moisture content of over 80%, separating gravel and clay. This ensures smooth excavation without blockage and maximizes shield machine excavation efficiency.

The agricultural and food industries meet cleanliness requirements. In grain processing, stainless steel models with food-grade certification can screen weeds and stones from wheat and rice, achieving a 98% impurity removal rate. The screens are easily removable and support CIP online cleaning, meeting GMP standards. In fruit and vegetable processing, specialized screens with apertures of 5-8mm are customized for materials like mango peels and cores and apple pomace. Combined with a gentle screening mode, they separate impurities while protecting the fruit pulp, providing high-quality raw materials for organic fertilizer granulation. In livestock and poultry manure treatment, sealed equipment achieves solid-liquid separation, reducing the moisture content of the dry residue to below 60%, for direct delivery to composting systems, contributing to the development of circular agriculture.

3. Operational and Economic Advantages: Cost Reduction and Efficiency Improvement for Long-Term Benefits

Zhongcheng drum screens were designed from the outset to balance short-term investment and long-term operation and maintenance costs. This approach creates sustainable economic benefits for customers by extending service life, simplifying maintenance, and reducing energy consumption.

Equipment lifespan and reliability reduce replacement costs. Core components are made of high-quality materials: the drive motor uses a Siemens variable-frequency motor with a failure rate of less than 0.5%; the bearings use imported SKF sealed bearings, offering a maintenance-free cycle of up to 12 months; and the screen features a quick-release mechanism, reducing replacement time to less than 30 minutes. According to customer data, the Zhongcheng drum screen has a mean time between failures (MTBF) of 1,200 hours, a 60% increase over the industry average. The overall equipment lifespan exceeds five years, far exceeding the three-year replacement cycle of standard equipment.

An intelligent operation and maintenance system reduces manual labor. Equipped with multi-dimensional sensors for vibration, temperature, and torque, the system monitors operating status in real time through an IoT platform. Automatic warnings are issued when screen wear exceeds a threshold, and a reverse cleaning process is triggered when material blockage occurs within the drum. Remote diagnostics allow engineers to troubleshoot problems online, reducing response time to within two hours and minimizing on-site downtime. For large-scale production lines, the central control system can coordinate multiple devices, automatically adjusting speed and screening parameters based on feed rate. Each production line requires only one inspector, reducing labor costs by 70%.

The system offers significant energy savings and overall cost advantages. Driven by a permanent magnet synchronous motor, it consumes 20%-30% less energy than traditional asynchronous motors. Based on a 10-hour daily operation and an industrial electricity price of 1 yuan per kWh, a single device can save over 15,000 kWh of electricity annually. Combined with the "trade-in" policy, a 15%-20% discount on old equipment can be applied toward the purchase of a new device, further reducing initial investment. Based on a full lifecycle cost analysis, the Zhongcheng drum screen offers a return on investment (ROI) exceeding 25% compared to similar products.

4. Full-Service Guarantee: Worry-free from selection to operation and maintenance

Zhongcheng has established a comprehensive service system covering pre-sales, sales, and after-sales, addressing various customer challenges in equipment selection, installation, and maintenance. Its service response speed and professionalism are industry-leading.

Pre-sales customized services precisely match customer needs. A professional team conducts in-depth on-site surveys and develops solutions based on material characteristics, production capacity targets, and site conditions. For example, in remote mining projects, equipment dimensions are optimized to accommodate height restrictions on mountain roads; in food processing plant projects, materials and structures are adjusted to meet hygiene certification requirements. Equipment commissioning services are provided, allowing customers to bring materials for on-site screening tests to ensure that parameters meet standards before signing a contract, thus avoiding the risk of misselection.

Post-sales installation and training ensure rapid commissioning. A seasoned installation team with over 10 years of experience provides one-stop installation and commissioning services, ensuring that large equipment can be installed within 72 hours. Theoretical and practical training is provided for operators, covering equipment principles, parameter adjustment, and daily inspections, ensuring independent team operation and maintenance. Equipment operating manuals and video tutorials are provided to facilitate subsequent personnel replacement training.

After-sales response and spare parts supply are timely and efficient. We provide 24/7 service. Upon receiving a fault report, we arrive on-site within 2 hours for urban customers and 48 hours for remote areas. We have established eight major spare parts warehouses nationwide, enabling same-day delivery of common parts (such as screens, bearings, and seals), while special parts are delivered within 7 days. We offer an annual maintenance package, with engineers performing regular on-site inspections, replacing wearing parts, and optimizing operating parameters to maintain equipment production capacity above 95% of the designed value.

Zhongcheng's drum screen's core competitiveness lies in its deep integration of technological innovation, scenario-specific customization, economical operation and maintenance, and professional services. From its anti-clogging and wear-resistant structural design to customized solutions for all industries, from cost reduction and efficiency improvement through intelligent operation and maintenance to comprehensive service assurance, each advantage directly addresses the core needs of customers in production. Whether it is an environmental protection enterprise pursuing efficient screening or a mining user dealing with high-wear conditions, choosing Zhongcheng drum screen is not only purchasing a piece of equipment, but also obtaining a set of screening solutions that adapt to their own needs and guarantee long-term benefits. This is the key to its standing out in the fierce market competition.

Save Time! Get A Detailed Quotation Quickly.