In mining, construction waste recycling, and other fields, screening equipment often faces challenges such as low efficiency, clogging, and high losses, hindering both production continuity and economic viability. The Zhongcheng Finger Screen leverages structural innovation and technological upgrades to address these challenges faced by traditional equipment. Its core design, based on a gate-shaped bar design, integrates a high-efficiency vibration system with flexible adaptability solutions, achieving breakthroughs in screening efficiency, durability, and environmental friendliness. It has become a key piece of equipment driving upgrades in the screening industry, providing efficient solutions for diverse production scenarios.

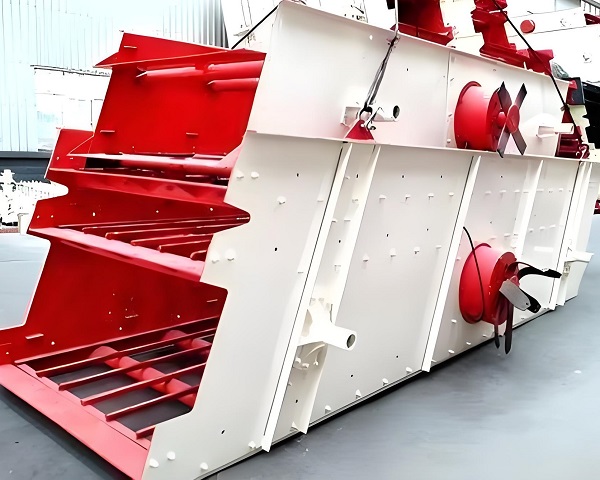

Structural Design: The Technical Foundation of Sturdy and Durable Products

The Zhongcheng Finger Screen's structural innovations underpin its core competitiveness. Every detail of its design is centered around the three core objectives of high strength, ease of maintenance, and long life. The screen deck utilizes a gate-like, integrated bar design. Two high-strength alloy bar supports and a wide-section bar beam form a similar, gate-like load-bearing structure. The bar beam cross-sectional width is precisely controlled between 2 and 8 cm. Combined with an adjustable support height of 40 to 100 cm, this creates a gradient load-bearing framework capable of directly withstanding the impact loads of large materials weighing over 500 kg, addressing the problem of traditional screen decks being susceptible to deformation due to impact.

The key bar components are made of high-quality spring steels such as 65Mn and 55CrSi. They undergo a specialized "intermediate-frequency quenching + low-temperature tempering" process, achieving a surface hardness of HRC 55-60 while maintaining excellent core toughness, achieving both rigidity and elasticity. Bar length is strictly controlled between 220 and 360 mm, with a spacing tolerance of no more than ±0.5 mm. This ensures screening accuracy while preventing vibration resonance and deformation failure caused by excessive length.

The equipment utilizes a modular architecture. The vibrating frame is a rectangular rigid frame welded from Q345B low-alloy steel plates. Ultrasonic testing has been performed on the weld seams to ensure they are free of defects such as pores and cracks. Wear-resistant rubber baffles, 15 cm above the screen surface, are installed on both sides to effectively prevent material leakage. The bars are secured with quick-release slots and high-strength bolts. Wear-resistant nylon width adjustment modules, ranging from 1 to 3 cm, can be inserted between the bars to enable precise adjustment of the screen gap within a range of 5 to 100 mm. No specialized tools are required, and a single operator can adjust the parameters of a set of screens in 15 minutes, significantly reducing maintenance.

The entire machine utilizes an optimized design combining a reinforced frame and lightweight components. This results in over 30% greater rigidity and component strength compared to traditional carbon steel equipment, while reducing overall weight by 15%. The compact and attractive design also increases unit volume processing capacity by 25% compared to similar equipment, making it ideal for production line layouts with limited space.

Performance Advantages: Core Performance of High Efficiency and Low Consumption

1. Superior Screening Efficiency

Equipped with proprietary dual-eccentric shaft vibrator technology, the vibrator is forged from a single piece of 45-gauge steel. The eccentric weight can be adjusted between 5 and 20 kg depending on the material characteristics. The vibrating force is evenly transmitted through the screen box to every bar on the screen surface, forcing the material to form a parabolic motion trajectory with an amplitude of 8-12 mm and a frequency of 800-1200 r/min. A single lift height of 15-20 cm can be achieved, ensuring sufficient screening of fine material and avoiding screening dead zones caused by material compaction.

The scientifically designed tilt angle ranges from 21° to 35°, and hydraulic adjustment allows for stepless adjustment of the tilt angle, precisely controlling the residence time for materials of varying specific gravities. For heavy materials like ore, the tilt angle is adjusted to 30° to 35°, with a residence time of 3 to 5 seconds, ensuring rapid screening. For lightweight materials like garbage, the tilt angle is adjusted to 21° to 25°, with a residence time of 8 to 10 seconds, ensuring thorough separation. Third-party testing has shown that its screening efficiency is 40% higher than that of conventional vibrating screens, with a processing capacity 2 to 3 times that of traditional equipment. In a construction waste treatment project, it can process 80 to 120 tons of material per hour, precisely separating bricks, concrete blocks, and lightweight waste with a separation purity exceeding 95%, far exceeding the industry average of 85%.

2. Anti-clogging and Self-cleaning Capabilities

The unique elastic deformation mesh design allows the bars to undergo a slight elastic deformation of 0.5-1mm during vibration. Combined with the trapezoidal layout of the extended screen surface, the open area ratio is increased to over 60%, a 20% increase compared to traditional flat screens. This allows materials to flow in a thin layer across the screen surface, increasing the flow rate by 30% and effectively reducing material accumulation.

For high-moisture (above 20% moisture content) and high-viscosity materials, the screen surface is equipped with a dedicated self-cleaning device. The high-molecular polyurethane elastic material embedded in the base of the bars generates secondary high-frequency vibrations of 1000-1500 r/min during vibration, creating an "active cleansing" effect, fundamentally solving the clogging and entanglement problems common with traditional screens. In a stale domestic waste treatment plant, the equipment operated continuously for 72 hours without clogging, maintaining a screen surface cleanliness of over 98% for waste containing 30% plastic, fiber, and other entanglement-prone materials. Conventional equipment, on the other hand, required shutdown and cleaning every four hours, resulting in a significant efficiency gap.

3. Low Energy Consumption and Quiet Operation

The system utilizes an imported vibration motor as the excitation source. With an IP65 protection rating and Class F insulation, it consumes 20% less energy than a motor of the same power and significantly improves operational stability, achieving a mean time between failures of over 20,000 hours. Six sets of composite rubber damping springs with a spring stiffness of 150 N/mm and a damping ratio of 0.25 are installed at the bottom of the equipment, reducing vibration transmission to below 15%, preventing vibration from affecting the foundation and surrounding equipment.

The optimized bar buffer structure and elastic rubber pads at the bar-to-cage connection reduce metal-to-metal collision noise. Field measurements show the equipment's operating noise is kept below 75 decibels, well below the industry average of 90 decibels. When operated in a closed factory, no additional soundproofing is required to meet occupational health standards.

Adaptability: Flexible Application in Multiple Scenarios

The Zhongcheng Finger Screen boasts exceptional adaptability, driven by its adjustable screening system and customized configuration, offering precise solutions tailored to different industries and material characteristics. By replacing width adjustment modules with varying thicknesses, the screen gap can be precisely adjusted to 1mm increments within a range of 5 to 100mm. With bar widths of various materials (spring steel, stainless steel, wear-resistant ceramic, etc.), it meets diverse needs for ore grading, waste sorting, building material screening, and coal desliming.

To address specific industrial environments, we offer two basic structures: open and closed. The open type features an open screen box design and a rain cover, making it suitable for open environments such as open-pit mines and construction aggregate storage yards, facilitating material observation and heat dissipation. The closed type utilizes a fully sealed screen box structure, equipped with a dust cover, odor collection port, and noise reduction layer, making it suitable for handling odorous materials such as municipal waste and food waste, effectively controlling secondary pollution.

Its application areas cover all industries: In the mining industry, as a pre-screening device before primary crushing, it can efficiently separate soil and ore with a particle size of less than 50mm, improving subsequent crusher processing efficiency by 25%, reducing crusher wear, and extending the life of wearing parts by 30%. In construction waste processing, it integrates dual functions of uniform feeding and coarse-fine separation to separate concrete blocks, bricks, and lightweight debris, achieving a coarse aggregate recovery rate of 90%, which can be directly used in recycled aggregate production. In stale waste processing lines, the gate-type bar structure easily separates large hard materials with a diameter greater than 100mm from soft debris, providing pure raw materials for subsequent air separation and magnetic separation, and improving overall processing line efficiency by 20%.

Furthermore, the equipment can be customized to meet site requirements, with dimensions ranging from 2.5m x 1.2m to 6m x 2.5m, requiring a minimum floor space of just 3 square meters. This makes it suitable for compact production line layouts, such as basements and renovations of older factories. It also supports the use of multiple units in series or parallel to meet varying processing capacity requirements.

Environmental and Economical Features: The Dual Value of Sustainable Development

In terms of environmental protection, the Zhongcheng Finger Screen uses an efficient pre-screening process at the front end to pre-separate fine materials and impurities that do not require crushing, reducing wasted work in subsequent crushing and grinding equipment. This reduces overall production line energy consumption by over 30%. For an aggregate production line with an annual output of 1 million tons, this can save approximately 800,000 yuan in electricity costs annually. The enclosed equipment is equipped with a high-efficiency dust cover and a pulse dust collector interface, keeping dust emissions below 10mg/m³. In waste treatment, its efficient separation capabilities increase the recovery rate of recyclables such as plastics and metals to 80%, a 30 percentage point increase compared to traditional equipment, contributing to the development of a circular economy and reducing landfill volume.

In terms of economic value, the wear-resistant spring steel rods used in this equipment have a service life of 15,000 hours, three times that of ordinary carbon steel rods. The stainless steel rods have a service life of up to 30,000 hours, significantly reducing the frequency of rod replacement and reducing replacement costs by 60%. The modular structure facilitates maintenance, allowing routine inspections and component replacement without disassembly. Annual downtime for maintenance is limited to 20 hours, far below the industry average of 80 hours, effectively ensuring production continuity.

According to user feedback, production lines equipped with Zhongcheng Finger Screens can reduce overall operating costs (including energy consumption, maintenance, and labor) by 15%-20%. For example, for a 500-ton daily construction waste processing line, this can save approximately 600,000 yuan in annual operating costs, shortening the payback period to 12-18 months and achieving profitability 6-12 months earlier than traditional equipment. Furthermore, all core components come with an 18-month warranty, and 30 after-sales service locations provide 24-hour response and repair, further reducing user risk.

The Zhongcheng Finger Screen is built on structural innovation, building advantages through performance upgrades and expanding its application through scenario adaptation, creating a market-leading advantage with dual value. Its gate-type bars and modular design ensure durability and ease of maintenance. Its dual eccentric shaft excitation and self-cleaning system deliver high efficiency and low energy consumption. A variety of configurations are available to meet the needs of all industries. It not only reduces the energy consumption and cost of the production line, but also helps environmental protection and resource recycling, effectively solves the pain points in the screening field, provides strong support for enterprises to improve quality and efficiency, and demonstrates the industrial value of technological innovation.

Save Time! Get A Detailed Quotation Quickly.