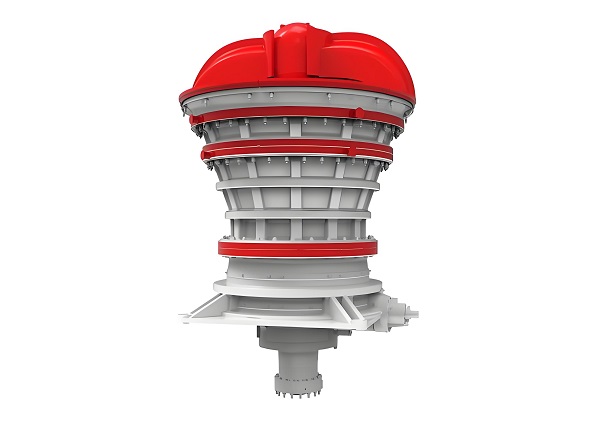

As the core equipment in the coarse crushing stage of construction waste, the gyratory crusher is a key support for achieving the goals of "reduction, resource recovery, and harmlessness" in the treatment of construction waste. It is particularly suitable for handling construction waste with complex composition, a high proportion of large materials, and uneven hardness. The construction waste-specific gyratory crusher, relying on a customized heavy-duty structure and the principle of layered crushing, plays a crucial role throughout the entire waste crushing process. It not only solves the problem of storing and transporting large pieces of waste but also lays the foundation for subsequent resource utilization, while simultaneously considering efficiency, environmental protection, and economy. Its core functions are detailed below:

1. High-efficiency volume reduction at the front end, solving pain points in waste storage and transportation, and reducing overall disposal costs. Construction waste raw materials contain a large number of large, hard materials, such as whole bricks, large blocks of concrete, reinforced concrete blocks, and waste stone. These materials are large in volume and high in density, not only occupying a large amount of transportation space and disposal sites but also easily scattering and generating dust during transportation, significantly increasing transportation frequency and costs, and putting great pressure on the receiving and stacking of waste disposal sites. The gyratory crusher, with its powerful layered crushing capability, utilizes the combined force of the crushing cone and the fixed cone to rapidly crush large pieces of construction waste with a diameter of 500-2000mm into uniform particles of 100-300mm, achieving a crushing ratio of up to 15:1. A single unit can process 100-500 tons per hour, significantly reducing the volume of construction waste by 60%-80% in a short time. This efficient volume reduction allows for the consolidation and transport of large pieces of waste that would otherwise require multiple truckloads, greatly reducing transport frequency, transportation costs, and fuel consumption. It also reduces the land area required for waste dumping, alleviating storage pressure at landfills and mitigating environmental pollution risks such as dust and leakage from open-air waste storage. This lays a solid foundation for the subsequent storage, transportation, and disposal of construction waste, making it particularly suitable for the large-scale processing needs of large demolition sites and large-scale construction waste disposal sites, significantly improving the efficiency and economy of construction waste disposal.

2. Pre-treatment purification and impurity removal protects subsequent equipment and ensures continuous operation of the production line. Construction waste is extremely complex in composition, containing not only large, hard materials but also impurities such as wood, plastic, fabric, and steel bars. If these foreign objects, such as steel bars and large pieces of metal, directly enter subsequent crushing, screening, and sorting equipment, they can easily cause jamming, wear, and malfunctions, leading to production line downtime and impacting processing efficiency. Conversely, if uncrushed large pieces of material directly enter subsequent equipment, they can cause screen blockage and incomplete sorting, further reducing the effectiveness of subsequent processing. A gyratory crusher can achieve preliminary separation of hard materials and impurities during the crushing process. Its heavy-duty crushing chamber, combined with a hydraulic overload protection system, can automatically identify and discharge foreign objects such as steel bars and large pieces of metal mixed in with the waste, preventing them from entering subsequent equipment and causing damage, reducing equipment downtime, and lowering maintenance costs. Simultaneously, the crushing process can initially remove impurities such as mud, sand, and dust adhering to the surface of hard materials, separating lightweight impurities such as wood and plastic from the hard crushed material. This facilitates precise sorting by subsequent eddy current separators and AI vision sorting robots, improving material purification efficiency, clearing obstacles for subsequent processing stages, and ensuring the efficient and continuous operation of the entire construction waste treatment production line.

3. Adaptable to multi-stage crushing processes, providing a high-quality material foundation for waste resource recycling. The core of construction waste resource utilization is processing hard crushed material into recycled aggregate for use in the production of building materials such as road base layers, concrete products, and permeable bricks. The particle size, gradation, and purity of the recycled aggregate directly determine its utilization value. As the front-end coarse crushing equipment in a multi-stage crushing process, the gyratory crusher's core function is to provide uniformly sized and reasonably graded materials for subsequent medium and fine crushing stages, avoiding problems such as incomplete crushing and uneven output particle size caused by large pieces of material directly entering the medium and fine crushing equipment. The gyratory crusher can remotely and precisely adjust the discharge port size via a hydraulic adjustment system, flexibly controlling the output particle size to meet the particle size requirements of different recycled aggregate production. The crushed material is cubic particles with low needle-like and flaky content, minimal powder, and a reasonable gradation, meeting relevant standards for recycled building aggregates. The material after coarse crushing can be directly fed into a Zhongcheng impact crusher for medium and fine crushing, further processing it into qualified recycled aggregates. This effectively improves the quality and utilization rate of recycled aggregates, promoting the transformation of construction waste from "waste" to "resource," and contributing to the development of a circular economy. This is the core resource utilization value of the gyratory crusher in waste crushing.

4. Adaptable to harsh working conditions, ensuring stable and continuous crushing operations, and reducing manual labor intensity. Construction waste crushing is mostly carried out in open or semi-open environments under harsh conditions. The material has uneven hardness and diverse impurities, placing extremely high demands on the wear resistance, impact resistance, and anti-clogging performance of the crushing equipment. Traditional coarse crushing equipment is prone to problems such as material jamming, rapid wear, and frequent malfunctions when processing this type of waste, requiring frequent shutdowns for cleaning and maintenance. This not only affects crushing efficiency but also increases the intensity of manual operation and safety hazards. The gyratory crusher is custom-designed for crushing construction waste. Its heavy-duty frame undergoes stress-relief through aging treatment, resulting in strong load-bearing capacity and impact resistance, capable of withstanding the violent impact of large pieces of material without easily deforming. The crushing cone is made of high-manganese steel alloy with a wear-resistant layer welded on, offering excellent wear resistance and impact resistance, extending its service life by more than 30% compared to traditional gyratory crushers. Simultaneously, the equipment is equipped with a hydraulic overload protection system and a sealing dustproof device. The hydraulic system automatically retracts the crushing cone when foreign objects are detected jamming, and automatically resets after expelling the foreign objects, eliminating the need for manual shutdown for cleaning. The sealing dustproof design effectively prevents dust leakage during crushing, protecting internal components from dust wear and meeting national environmental protection standards. Furthermore, the equipment is equipped with a PLC intelligent control system, which can monitor the equipment's operating status in real time, support remote monitoring and fault early warning, and achieve "proactive early warning" maintenance. This reduces manual inspection and operational intensity, ensuring continuous and stable 24-hour operation of the crushing process, significantly improving the efficiency and safety of waste crushing.

5. Strong synergy and compatibility, perfecting the waste crushing and treatment system, and adapting to large-scale disposal needs. With the acceleration of urban renewal, the output of construction waste has surged. Large-scale and intelligent disposal has become the industry trend, and single crushing equipment can no longer meet the needs of efficient processing of large quantities of waste. The gyratory crusher has extremely strong compatibility and can be seamlessly connected with equipment such as bar screens, impact crushers, vibrating screens, magnetic separators, and water separators to build a complete construction waste crushing and treatment production line from "coarse screening—coarse crushing—medium and fine crushing—grading—sorting—resource utilization". In this system, the gyratory crusher plays a crucial role in the initial coarse crushing stage. After crushing large pieces of waste, the material is graded by a vibrating screen. Qualified material enters the subsequent medium and fine crushing stages, while unqualified material is returned for heavy crushing, achieving closed-loop crushing. Metal impurities such as reinforcing bars, initially separated, can be precisely recovered by a subsequent magnetic separator. Lighter impurities are separated and reused by sorting equipment. The crushed hard material undergoes further processing to become recycled aggregate, realizing the resource utilization of all components of construction waste. This synergistic effect makes the gyratory crusher not just a single crushing device, but also the "core hub" of a large-scale construction waste crushing and processing production line. Modular customized designs can be provided according to customer processing volume and site size, adapting to different scales of disposal needs, from large-scale construction waste disposal sites and building material recycling plants to demolition sites, promoting the development of construction waste crushing and disposal towards large-scale, intelligent, and resource-oriented directions.

The role of the gyratory crusher in waste crushing runs through the entire process of construction waste disposal. It not only achieves efficient volume reduction and impurity removal pretreatment of waste, providing a high-quality foundation for resource utilization, but also ensures the stable and efficient operation of the processing line, reducing disposal costs and environmental pollution. Compared to traditional coarse crushing equipment, it is better suited to the complex crushing conditions of construction waste due to its customized design, high efficiency and energy saving, wear resistance and durability, and intelligent convenience. It effectively improves the crushing and disposal efficiency and resource utilization rate of construction waste, provides reliable equipment support for the resource utilization of construction waste in my country, and fully embodies the core concept of "technological innovation, precision and efficiency, and green environmental protection", helping to achieve the harmless disposal and recycling of construction waste.

Save Time! Get A Detailed Quotation Quickly.