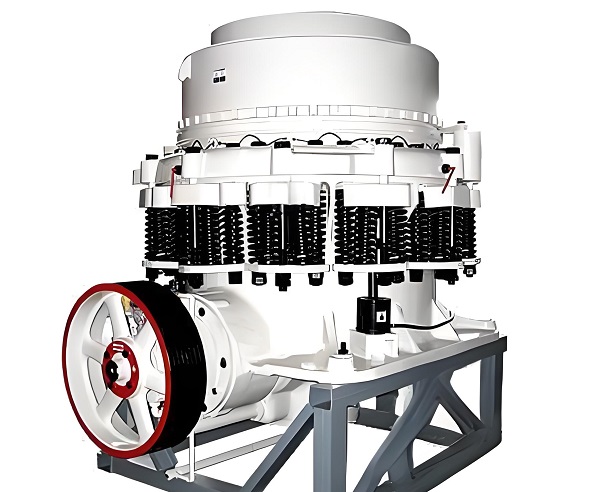

Preface: The spring cone crusher, as a leader in the crushing field, has garnered significant attention due to its exceptional performance and wide range of applications. It is an advanced crushing equipment characterized by high power, large crushing ratio, and high productivity. With its outstanding performance and extensive application areas, the spring cone crusher has become an indispensable and vital equipment in the crushing field.

Cone Crusher

A. Characteristics of spring cone crusher:

The spring cone crusher is a crushing equipment widely used in various fields such as environmental protection, construction, metallurgy, road building, and chemistry. It is primarily used for crushing concrete with medium or high hardness, as well as various ores and rocks. Its characteristics can be summarized as follows:

1. With reliable structure and high production efficiency, the crushed material has uniform particle size and high cubic content, reducing the amount of needle-like and flaky materials, thus meeting the material requirements of different customers.

2. The spring safety system, serving as an overload protection device, allows foreign objects and iron pieces to pass through the crushing chamber without endangering the crusher, thereby enhancing the safety and stability of the equipment.

3. By adopting both dry oil and water sealing methods, the disadvantages of easily clogged water supply and drainage systems and the defects of easy mixing of water and oil are avoided. This isolates the stone powder from lubrication, ensuring reliable operation and effectively extending the service life of sliding bearings and thrust ball bearings.

4. It features low noise, minimal vibration, and few malfunctions, allowing for long-term operation with stable performance and a low failure rate. Even working at night, it will not affect the lives of the people around it.

5. Energy-saving and environmentally friendly, with significant energy-saving effects compared to other equipment, saving costs for customers.

Cone Crusher

B. Structural advantages of the spring cone crusher:

1. High production capacity: better quality.

2. Safety device: It significantly reduces downtime.

3. Cast steel structure: The body is made of cast steel structure, with reinforcing ribs provided at the heavy-load areas.

4. Adjuster: It can quickly adjust the size of the crushed material output.

5. Protection device: A spring-loaded protection device is provided.

6. Lubrication system: Equipped with a comprehensive lubrication system, it will automatically shut down in case of excessive temperature or slow flow rate.

7. Good sealing performance: The internal structure boasts excellent sealing performance, effectively protecting the equipment from dust and other small particles.

8. The consumable parts have a long service life and low operating costs.

9. The use of grease sealing isolates dust from lubricating oil, extending the service life of the equipment.

10. The lubrication station provides continuous oil supply for lubrication, reducing downtime for maintenance.

11. Reliable structure and stable performance.

Cone Crusher

C. Advantages of spring cone crushers:

1. Efficient crushing: The spring cone crusher adopts the laminated crushing principle, significantly reducing needle-like and flaky materials and enhancing processing capacity. The combination of its high-performance crushing chamber and high crushing frequency significantly boosts processing capacity.

2. Iron passing protection: The equipment design incorporates a bidirectional iron passing release hydraulic cylinder, which enables iron pieces to pass through the crushing chamber, reducing downtime caused by debris entering the crushing chamber and enhancing the reliability of the equipment.

3. Safe and durable: The spring cone crusher features a large-diameter main shaft and a heavy-duty main frame, ensuring the equipment is sturdy and durable. Additionally, its multi-point controlled independent lubrication system ensures dual protection for bearing lubrication, enhancing the equipment's durability and reliability.

4. Easy to operate and maintain: The spring cone crusher is easier to automate, enhancing its reliability and prolonging its lifespan. Additionally, lubrication and maintenance of the equipment are relatively simple, reducing maintenance costs.

5. Long service life: strong applicability.

6. Higher production capacity and better quality.

Cone Crusher

D. Disadvantages of spring cone crusher:

1. Dust prevention issue: An unreasonable dust prevention device may lead to blockage of the dust prevention pipeline, allowing dust to enter the lubrication system, causing lubricant contamination and damage to the oil pump. This requires frequent replacement of lubricant, increasing maintenance costs.

2. Insufficient protective devices: Sometimes, due to the unreasonable design of protective devices, the crushing chamber may become filled with ore after the crusher gets stuck and stops, requiring manual cleaning, which affects normal operation.

3. Limited crushing surface: The traditional spring cone crusher utilizes a horizontal copper sleeve for its horizontal drive shaft, which has a short lifespan, low rotational speed, and high failure rate, resulting in limited production capacity.

4. Long maintenance cycle: The main vulnerable parts of the cone crusher, such as the moving hammer liner and the nail hammer liner, wear out quickly and need to be replaced regularly, which increases maintenance costs.

Technical parameters of spring cone crusher:

| Model | Diameter of crushing cone (mm) | Adjustment range of ore discharge opening (mm) | Maximum feed particle size (mm) | Output (t/h) | Motor power (kw) | Weight (t) | External dimensions (mm) |

| ZCSC-600 | 600 | 12-25 | 65 | 15-25 | 30 | 5.5 | 1740×1225×1940 |

| ZCD-600 | 600 | 3-13 | 36 | 5-23 | 30 | 5.5 | 1740×1225×1940 |

| ZCSC-900 | 900 | 15-50 | 115 | 50-90 | 55 | 10.18 | 1990×1640×2380 |

| ZCZ-900 | 900 | 5-20 | 60 | 20-65 | 55 | 10.19 | 1990×1640×2380 |

| ZCD-900 | 900 | 3-13 | 40 | 15-50 | 55 | 10.27 | 1990×1640×2380 |

| ZCSC-1200 | 1200 | 20-50 | 145 | 110-200 | 110 | 24.7 | 2805×2300×2980 |

| ZCZ-1200 | 1200 | 8-26 | 100 | 50-150 | 110 | 25 | 2805×2300×2980 |

| ZCD-1200 | 1200 | 3-15 | 50 | 18-105 | 110 | 25.6 | 2805×2300×2980 |

| ZCSC-1750 | 1750 | 25-60 | 215 | 280-480 | 155-160 | 50.6 | 3610×2950×4185 |

| ZCZ-1750 | 1750 | 10-30 | 185 | 115-320 | 155-160 | 51 | 3610×2950×4185 |

| ZCD-1750 | 1750 | 5-15 | 85 | 75-230 | 155-160 | 50.5 | 3610×2950×4185 |

| ZCSC-2200 | 2200 | 30-60 | 300 | 590-1000 | 260-280 | 84 | 4790×3430×5080 |

| ZCZ-2200 | 2200 | 10-30 | 235 | 200-580 | 260-280 | 85 | 4790×3430×5080 |

| ZCD-2200 | 2200 | 5-16 | 110 | 120-370 | 260-280 | 85 | 4790×3430×4852 |

PS: The spring cone crusher boasts a wide range of applications and notable product features and advantages, yet it also presents certain drawbacks that require attention. When selecting and utilizing this equipment, it is imperative to weigh and consider specific needs and scenarios. Characterized by its substantial crushing force, high efficiency, large processing capacity, low operational costs, convenient adjustment, and cost-effectiveness, the spring cone crusher stands as the preferred choice in the crushing sector.

Save Time! Get A Detailed Quotation Quickly.