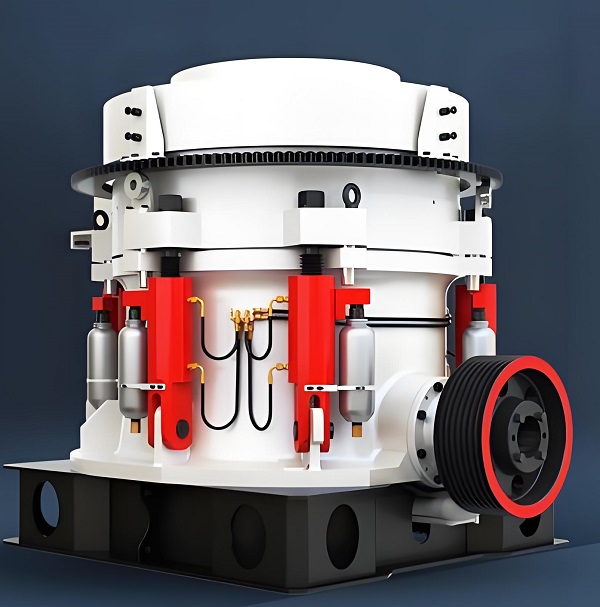

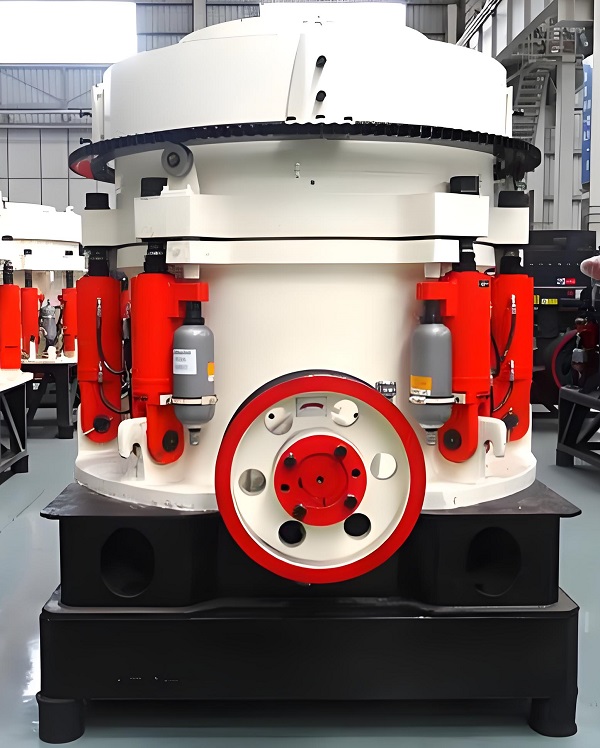

Preface: The multi-cylinder hydraulic cone crusher is a typical crushing equipment for medium and fine crushing of hard materials. It is developed based on the spring cone crusher, and its basic structure is similar to that of the spring cone crusher. The multi-cylinder hydraulic cone crusher is a new generation of cone crusher successfully developed in the industry. It breaks through the previous design concept of cone crusher structure, adopts a structure with a fixed main shaft and an eccentric sleeve rotating around the main shaft, and applies the laminated crushing principle, significantly improving the crushing capacity and product quality. The supporting hydraulic lubrication system ensures the operation of the equipment. The structure, product characteristics, and advantages of the multi-cylinder hydraulic cone crusher are introduced as follows:

A. The structural composition of the multi-cylinder hydraulic cone crusher. The multi-cylinder hydraulic cone crusher is mainly composed of the following components:

1. Fixed cone part: It is fixed on the frame and forms a crushing chamber with the movable cone.

2. Moving cone part: It is installed on the eccentric sleeve and performs a swinging motion as the eccentric sleeve rotates, working together with the fixed cone to complete the crushing of materials.

3. Eccentric sleeve part: The spindle rotation drives the cone to perform a swinging motion, achieving efficient crushing operations for the crusher.

4. Transmission part: It includes the transmission shaft, gears, etc. The motor drives the crusher, transmitting rotational power through the connecting device to achieve efficient crushing operations. Among them, the large bevel gear changes the direction of the transmission shaft, drives the eccentric sleeve, and realizes power transmission and direction conversion, connecting the motor and the crusher.

5. Frame section: The main structure that supports the entire crusher.

6. Adjustment ring: used to adjust the width of the crushing chamber and the size of the discharge opening.

7. Feed bin section: The entrance for materials to enter the crushing chamber.

8. Discharge port adjustment section: Adjust the size of the discharge port to meet the discharge requirements of different fineness levels.

9. Locking protection cylinder section: It consists of several locking protection cylinders, iron-passing protection accumulator, buffer accumulator assembly, and pipelines. Its main functions are iron-passing protection and cleaning of the crushing chamber.

10. Fan section: used for cooling and dust removal.

11. Motor Department: Provides the power source to drive the overall operation of the crusher.

12. Hydraulic station: Provides hydraulic power for the crusher and implements various hydraulic functions.

13. Lubrication station: Provides lubrication for the moving parts of the crusher.

In addition, there are some special tools and other components. Among them, the iron protection device of the multi-cylinder hydraulic cone crusher consists of multiple hydraulic cylinders, which are integrated with the locking protection device and installed at the joint between the upper and lower machines.

B. Working principle of multi-cylinder hydraulic cone crusher

When the motor starts, power is transmitted to the eccentric sleeve through the transmission shaft and gears, and the eccentric sleeve drives the moving cone to perform a swinging motion. As it approaches the fixed cone, the material is squeezed and bent by the moving cone, resulting in crushing; as it moves away from the moving cone, the crushed material falls from the bottom of the cone under the action of gravity. The entire crushing and discharging process proceeds sequentially along the inner wall. During normal crushing, the locking protection cylinder is used to absorb the impact caused by the bouncing of the adjustment ring due to a small number of hard materials during buffering.

During the operation of the multi-cylinder hydraulic cone crusher, the electric motor drives the eccentric sleeve to rotate through the V-belt, transmission shaft, and bevel gear pair. Under the action of the eccentric sleeve, the moving cone performs a swinging motion, causing the moving cone and the fixed cone to approach and deviate from each other intermittently. Materials are continuously squeezed and impacted within the crushing chamber, undergoing crushing. The crushed materials are discharged from the bottom. It is primarily used for crushing construction waste, secondary and tertiary crushing in metal mines and construction sandstone processing. Due to its strong crushing capacity and high output, it is more commonly used for crushing medium-hard materials.

C. Features and advantages of multi-cylinder hydraulic cone crushers

1. Good crushing performance: large crushing ratio, uniform output particle size, and high crushing efficiency.

2. Easy adjustment: The hydraulic system adjusts the width of the crushing chamber and the size of the discharge opening, enabling automated production.

3. Novel structure: It can effectively reduce impurities and minimize dust pollution.

4. Energy saving: Advanced crushing technology and hydraulic system are adopted to reduce energy consumption and production costs.

5. High degree of intelligence: simple operation, convenient maintenance, and high levels of automation and intelligence.

6. Fully hydraulic operation, easy to use: It is easy to achieve automation, and its reliability and service life are greatly improved. The hydraulic system automatically resets the moving cone that has retracted, maintaining the original ore discharge position and continuing to work.

7. Adopting a labyrinth seal device: This replaces the previously used water seal, effectively reducing dust ingress and extending the service life of the sliding bearing and thrust ball bearing, ensuring safe and reliable machine operation.

8. Reasonable structure and excellent crushing technology: reliable operation and low operating costs; optimized equipment component configuration and strong wear resistance, effectively reducing maintenance costs and extending equipment service life by more than 30%.

9. The laminated crushing principle is adopted: the crushed products are mostly cubes, reducing the amount of needle-like and flaky materials. Due to the optimized design of the multi-cylinder hydraulic cone crusher, the equipment failure rate has been reduced, greatly improving work efficiency.

10. It can be quickly loaded and unloaded; the particle size is uniform, and the sample preparation efficiency is high; it runs smoothly and has low noise.

Technical parameters of multi-cylinder hydraulic cone crusher:

| Model | Crushing chamber type | Standard type | Short-headed type | Production capacity (t/h) | Power (kw) | ||

|---|---|---|---|---|---|---|---|

| Feed inlet size (mm) | Opening edge (mm) | Feed inlet size (mm) | Opening edge (mm) | ||||

| ZCMHC200 | Coarse type | 185 | 19 | 76 | 10 | 145-250 | 132-200 |

| Medium | 125 | 17 | 54 | 6 | 135-235 | ||

| Thin type | 95 | 13 | 23 | 6 | 115-220 | ||

| Superfine | 75 | 10 | 10 | 5 | 90-190 | ||

| ZCMHC300 | Coarse type | 210 | 20 | 75 | 10 | 190-380 | 180-250 |

| Medium | 150 | 15 | 50 | 8 | 175-320 | ||

| Thin type | 105 | 10 | 20 | 6 | 145-280 | ||

| Superfine | 80 | 10 | 20 | 6 | 110-240 | ||

| ZCMHC400 | Coarse type | 250 | 25 | 90 | 10 | 285-560 | 280-355 |

| Medium | 195 | 20 | 50 | 8 | 250-490 | ||

| Thin type | 110 | 14 | 40 | 6 | 180-345 | ||

| Superfine | 90 | 10 | 30 | 6 | 135-320 | ||

| ZCMHC500 | Coarse type | 285 | 25 | 90 | 13 | 400-790 | 355-450 |

| Medium | 200 | 20 | 55 | 10 | 335-610 | ||

| Thin type | 133 | 16 | 40 | 8 | 280-460 | ||

| Superfine | 95 | 13 | 35 | 6 | 180-435 | ||

| ZCMHC800 | Coarse type | 297 | 32 | 155 | 13 | 425-1200 | 355-450 |

| Medium | 267 | 25 | 92 | 10 | 335-730 | ||

| Thin type | 219 | 16 | 33 | 8 | 260-500 | ||

| Superfine | - | - | - | - | - | ||

PS: The multi-cylinder hydraulic cone crusher, with its advantages of high efficiency, energy saving, and environmental protection, has been widely applied and recognized in multiple industries. The multi-cylinder hydraulic cone crusher boasts broad market prospects and development potential. With continuous technological innovation and sustained market development, Zhongcheng Machinery further expands its application fields and provides more efficient and environmentally friendly crushing solutions for various industries.

Save Time! Get A Detailed Quotation Quickly.