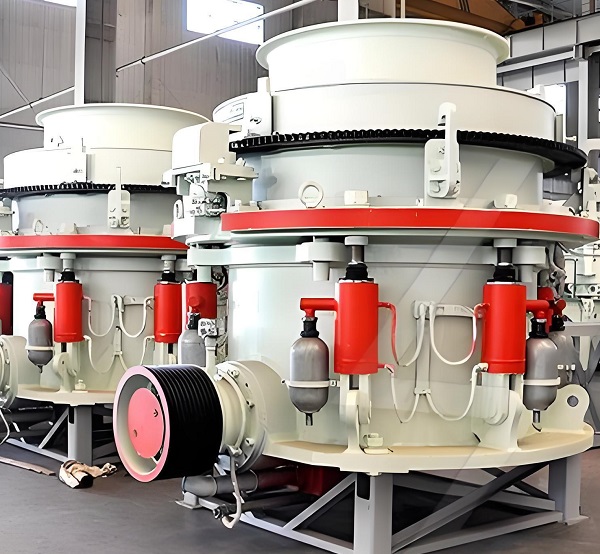

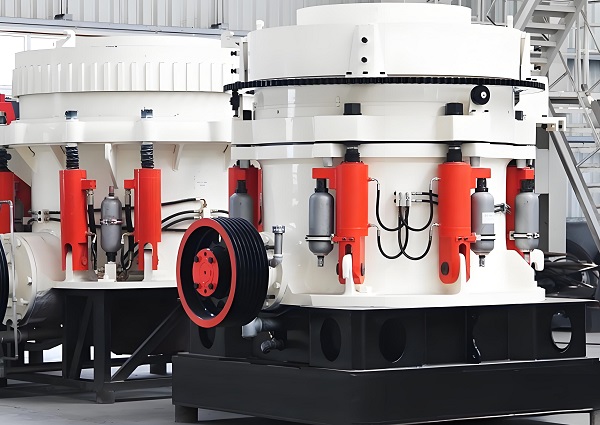

In heavy-duty crushing applications such as mining and building materials, hydraulic cone crushers, thanks to technological innovations driven by hydraulic systems, have surpassed traditional spring-type models in performance. Core to this dual system, "hydraulic adjustment + hydraulic safety," they address the pain points of traditional equipment, such as low adjustment precision and difficulty handling foreign objects stuck in the crusher. They offer both efficient crushing and stable operation. From structural design to performance, from application adaptation to technological upgrades, their value permeates the entire raw material processing chain. This article systematically analyzes the core features and key advantages of hydraulic cone crushers, exploring their application value through case studies, providing a reference for equipment selection and technological upgrades in the industry.

Core Structural Features: Hydraulic System-Driven Design Innovation

1. "Hydraulic Adjustment + Hydraulic Safety" Dual System Architecture

The most distinctive feature of the hydraulic cone crusher is its fully hydraulic control system, replacing the mechanical springs of spring-type crushers with hydraulic cylinders, creating an integrated "adjustment + safety" structure. Four to eight hydraulic cylinders are distributed around the upper circumference of the crusher, connecting the fixed cone to the frame. The cylinders extend and retract to precisely adjust the fixed cone position, enabling fine-tuning of the discharge opening with an adjustment accuracy of up to 0.5mm, far exceeding the 1mm accuracy of a spring-type crusher.

The hydraulic safety system responds more quickly. When uncrushable objects such as iron blocks enter the crushing chamber, the hydraulic system senses the sudden pressure increase within 0.1 seconds and rapidly retracts the cylinders to widen the discharge opening. Once the foreign object is expelled, the crusher automatically resets, requiring no manual intervention. Data from a granite mine in Henan Province shows that this system has reduced the equipment jam failure rate from 2% with a spring-type crusher to 0.3%, and shortened the time required to resolve a single jam from 30 minutes to 5 minutes.

2. Optimized Laminated Crushing Chamber Design

Inheriting and evolving the principle of laminated crushing, the hydraulic cone crusher's crushing chamber utilizes a "multi-curved chamber" design. Based on material characteristics, it can be divided into various chamber types—coarse crushing (C chamber), medium crushing (M chamber), and fine crushing (F chamber)—to accommodate varying particle size requirements. The optimized cavity curve prolongs material residence time within the cavity by 20%, increasing the number of squeezes and grinding cycles for more complete crushing.

Compared to spring-type crushers, the crushing chamber depth is 30% deeper, significantly increasing throughput. For example, the HST315 hydraulic cone crusher boasts a coarse crushing chamber capacity of 800-1200 tons/hour, a 15% increase over similar spring-type models. The fine crushing chamber discharge particle size can be stably controlled at 3-15mm, meeting the precise demands of manufactured sand production.

3. Intelligent Transmission and Lubrication System

The transmission system utilizes a "motor + gearbox + eccentric sleeve" direct drive configuration, coupled with variable frequency speed regulation technology. It automatically adjusts speed based on feed rate, covering a speed range of 50-200 rpm. It reduces speed and increases torque when crushing hard materials, while increasing speed and efficiency when crushing soft materials. The system's transmission loss is only 3%-5%, lower than the 5%-8% of spring-type crushers. The lubrication system has been upgraded to an "intelligent thin oil circulation" mode, equipped with triple monitoring of oil temperature, oil pressure, and oil level. It automatically filters the lubricating oil when contamination exceeds standards, and activates a cooling device when the oil temperature exceeds 60°C. Equipment at an Inner Mongolia iron mine remains stable in temperatures as low as -20°C, and the bearing life reaches 18 months, 50% longer than spring-type bearings.

Key Performance Advantages: Breakthrough Efficiency in Heavy-Duty Scenarios

1. Improved Crushing Efficiency and Processing Capacity

Precise hydraulic system control and optimized cavity geometry contribute to improved efficiency. Mainstream hydraulic cone crushers can achieve a processing capacity of 100-2000 tons/hour, far exceeding the 50-1500 tons/hour of spring-type crushers. In limestone crushing projects, the HP500 hydraulic crusher achieves a processing capacity of 500-800 tons/hour, a 25% increase over spring-type crushers of the same specification. Its efficiency advantage is particularly pronounced in the fine crushing process. Models utilizing "high-energy crushing" technology reduce energy consumption per unit output by 18%-25% compared to spring-type crushers. Data from a Shandong manufactured sand plant shows that replacing spring-type crushers with hydraulic cone crushers reduced energy consumption per ton of sand crushing from 12kWh to 9kWh, saving over 150,000 kWh of electricity annually.

2. Better product shape and more consistent gradation

Thanks to its multi-curved crushing chamber and precise discharge control, hydraulic cone crushers produce a more uniform particle shape, with a cubic content exceeding 80% and a flake content below 10%, surpassing the 70% cubic content and 15% flake content of spring-type crushers. This high-quality particle shape is in high demand in the high-end building materials sector. Basalt aggregate crushed by this technology has achieved 100% concrete compressive strength compliance in a Shanghai high-speed rail project, a 5% increase over aggregate produced by spring-type crushers. Furthermore, by adjusting the combined parameters of the discharge opening and rotational speed, precise control of material gradation is achieved. By optimizing these parameters, a commercial concrete plant in Yunnan Province increased the proportion of 10-20mm aggregate from 40% to 60%, perfectly matching the grading requirements of high-strength concrete.

3. Strong operational stability and lower maintenance costs

The rapid response of the hydraulic safety system significantly reduces the risk of equipment damage, enabling trouble-free operation of over 8,000 hours, a 30% increase compared to spring-type models. Statistics from a copper mine in Hunan Province show that hydraulic cone crushers require only 2-3 maintenance visits per year, compared to 5-6 for spring-type models, resulting in an increase in equipment utilization from 95% to 98%.

The life of wearing parts is significantly extended. Hydraulic models using high-chromium alloy liners achieve a liner life of 1,200-1,500 hours when crushing granite, a 25% increase compared to the 800-1,200 hours of spring-type liners. Hydraulic models also offer easier replacement of wearing parts. By lifting the fixed cone with a hydraulic cylinder, liner replacement time is reduced from four hours with a spring-type model to two hours, reducing annual operation and maintenance costs by 30%-40%.

4. Wider adaptability and strong application compatibility

Hydraulic cone crushers can process a wide range of materials with a compressive strength of ≤350 MPa, including hard materials such as granite, iron ore, and copper ore, as well as medium-soft materials such as limestone and gypsum. They are suitable for a wide range of applications, including mining, building materials, and metallurgy. For sticky materials, the hydraulic system allows for frequent adjustment of the discharge opening to prevent clogging, something difficult with spring-type models.

Their advantages are even more pronounced in mixed material crushing scenarios. At a comprehensive stone quarry in Hebei, hydraulic models maintain a stable throughput of 300 tons/hour by automatically adjusting the speed and discharge opening, while spring-type models experience fluctuations of up to 20% due to inconvenient adjustment.

Typical Application Scenarios and Value Realization

1. Mineral Processing: Core Equipment for Secondary and Fine Ore Crushing

In the metal ore beneficiation process, hydraulic cone crushers perform critical secondary and fine crushing tasks. A copper mine in Jiangxi Province uses an HPT500 hydraulic cone crusher to crush coarsely crushed ore to 10-25mm, improving particle size uniformity by 40%, increasing subsequent ball mill throughput by 22%, and boosting flotation recovery from 88% to 92%.

In the non-metallic mineral sector, its precise crushing characteristics can reduce over-crushing. After using this equipment at a graphite mine in Shandong Province, the proportion of graphite ore with a qualified particle size (15-30mm) increased from 82% to 95%, reducing the over-crushing rate by 12%, and significantly improving resource utilization.

2. Manufactured Sand Production: The Core Equipment for High-Quality Sand and Gravel

With the implementation of the ban on natural sand mining, demand for manufactured sand has surged, making hydraulic cone crushers the preferred choice for high-quality manufactured sand production. A manufactured sand plant in Henan uses a "jaw crusher + hydraulic cone crusher + sand making machine" process. The hydraulic cone crusher produces a continuously graded 5-10mm intermediate material. After shaping by the sand making machine, the finished sand has a stable fineness modulus of 2.6-3.0, meeting the first-class standard for construction sand. The price is 30 yuan/ton higher than that of ordinary sand.

3. Construction Waste Resource Utilization: A Powerful Tool for Crushing Hard-Core Materials

Construction waste contains a large amount of hard-core materials such as concrete blocks and scrap steel bars. The high crushing force of the hydraulic cone crusher and its safety system are highly compatible. In a construction waste treatment project in Beijing, this equipment crushes concrete blocks to less than 20mm. Metal foreign matter such as steel bars is automatically discharged through the hydraulic safety system. The purity of the recycled aggregate reaches 98%, and the annual processing capacity exceeds 3 million tons of construction waste.

Development Trends and Technology Upgrade Directions

Currently, hydraulic cone crushers are being upgraded towards intelligent, large-scale, and environmentally friendly designs. In terms of intelligence, models integrating AI visual recognition and IoT technology have enabled real-time monitoring of crushing chamber load and particle shape, automatically generating optimal operating parameters. In a pilot project, the qualified particle shape rate reached 95%.

There is a clear trend toward larger-scale production. To meet the needs of large-scale mines, ultra-large models with a processing capacity of 2,000 tons/hour have been put into operation. A single unit can meet the crushing needs of mines with a capacity of tens of millions of tons. Regarding environmental friendliness, the use of low-noise gearboxes and dust collection devices reduces operating noise to below 70dB and dust emission concentrations to less than 5mg/m³, meeting stringent environmental standards.

Hydraulic cone crushers, with their core technology of "hydraulic control + optimized chamber shape," surpass spring-type models in efficiency, particle shape, and stability, making them the upgraded choice for heavy-duty crushing applications. Their wide adaptability and significant performance advantages have led to their increasing application in mining, building materials, and other fields. With the integration of intelligent and green technologies, hydraulic cone crushers will further break through efficiency bottlenecks and provide more powerful equipment support for the efficient and low-carbon development of the raw materials processing industry.

Save Time! Get A Detailed Quotation Quickly.