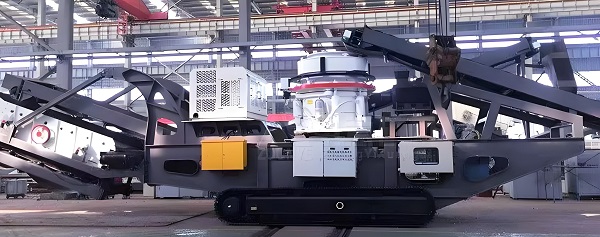

Editor's note: Mobile crushing station is an efficient and flexible crushing equipment widely used in construction waste treatment, mining, and construction engineering fields. Its biggest feature is its mobility, which allows it to quickly transfer to different work locations, adapt to various complex environments, and greatly improve work efficiency. Mobile crushing stations are usually equipped with advanced crushing equipment, such as jaw crushers, impact crushers, etc., which can meet the crushing needs of different materials. Meanwhile, its intelligent control system makes operation more convenient and reduces labor costs.

Mobile crushing station is a mechanical equipment that can crush large materials in multiple stages and screen them according to certain discharge specifications. Mainly used for screening and processing construction waste, metallurgy, chemical industry, building materials, water and electricity, and other materials that often require relocation operations, especially for the operation of mobile stone materials in highways, railways, water and electricity projects. Users can adopt various configuration forms according to the type, scale, and requirements of the processed raw materials and finished materials.

The quality and reputation of Zhengzhou Zhongcheng Machinery's mobile crushing station are guaranteed. Zhongcheng Machinery specializes in producing mobile crushing stations. With 10 years of manufacturing experience, we guarantee quality and reputation The manufacturer provides the following services for free: scheme design, equipment selection, technical support, installation guidance, high-quality after-sales service, etc

Mobile crushing stations are mainly used in the construction waste treatment industry, building materials industry, etc. Users can adopt various configuration forms according to the types, scales, and requirements of processed raw materials and finished materials. This complete set of crushing and screening equipment can be used for construction waste treatment, mining, building materials, highways, railways, water conservancy and other industries to complete crushing and screening operations in one go, producing the material particle size and output required by users. This mobile crushing and screening equipment consists of a primary crushing station, a secondary crushing and screening station, and a belt conveyor. Each crushing station is an independent working unit that can fulfill its different responsibilities. The belt conveyor is responsible for material transportation and stacking between each crushing station. The variety of mobile crushing and screening stations is complete, and the specifications are serialized. There is a wide range of choices for mobile crushing and screening stations, which can meet the needs of a large number of users.

A. Characteristics of Mobile Crushing Station:

The mobile crushing station has the characteristics of reasonable matching of crushing equipment at all levels, smooth discharge of the entire line process, reliable operation, convenient operation, and high efficiency and energy saving. Especially with good mobility, it can extend along with the raw material or construction site, and can be combined in various ways to meet different material needs.

1. Strong mobility: The tire mobile crushing station has a short length, and different crushing equipment is installed on independent movable chassis. The wheelbase is short, the turning radius is small, and it can be flexibly driven on ordinary roads and in work areas.

2. Integrated complete unit: The installation form of integrated unit equipment eliminates the complex site infrastructure installation operation of separate components, reducing material and labor consumption. The reasonable and compact spatial layout of the crew has improved the flexibility of site deployment.

3. Reduce material transportation costs: Mobile crushing stations can process materials on site without having to move them away for further processing, greatly reducing material transportation costs.

4. Direct and effective homework function: The integrated series of mobile crushing stations can be used independently or provide more flexible process configurations according to customer requirements for material types and products in the process, meeting various requirements such as mobile crushing and screening, making the generation organization and logistics transportation more direct and effective, and achieving maximum cost reduction.

5. Flexible combination and strong adaptability: The tire mobile crushing station can be combined into a "first crushing and then screening" or a "first screening and then crushing" process according to different crushing process requirements. The crushing station can be combined into a two-stage crushing and screening system for coarse crushing and fine crushing, or a three-stage crushing and screening system for coarse crushing, medium crushing, and fine crushing according to actual needs. It can also operate independently and has great flexibility.

B. Composition of mobile garbage crushing station:

The mobile crushing and screening equipment includes a primary crushing station, a secondary crushing and screening station, a belt conveyor, and other components.

Mobile crushing stations are flexible and convenient, with strong mobility, which can save a lot of infrastructure and relocation costs; It can crush materials on site and move with the advancement of the raw material mining face, thereby greatly reducing the transportation cost of materials. On the basis of the original technology, two new series and three smaller series of mobile crushing and screening equipment have been optimized and combined. Each series is divided into three series of mobile crushing stations: coarse and medium fine, which can fully adapt to various situations of mobile crushing and screening, truly creating more new business opportunities and reducing production costs for customers.

The design concept of the tire mobile crushing station is to fully adapt to various requirements of mobile crushing, provide customers with a new operating mode, and greatly reduce operating costs.

C. Classification of Mobile Crushing Stations

a. Composition of tracked mobile crushing station

The classification of tracked mobile crushing stations is generally similar to that of tire type mobile crushing stations, with the difference being their driving methods. They are divided into main series such as tracked counterattack mobile crushing stations, tracked vertical impact mobile crushing stations, tracked cone mobile crushing stations, tracked jaw mobile crushing stations, and tracked construction waste mobile crushing stations.

1. The components of the track impact mobile crushing station include: a sturdy frame, an E-type crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

2. The components of the tracked vertical impact mobile crushing station include: a sturdy frame, an jaw crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

3. The components of the tracked cone mobile crushing station include: a sturdy frame, an jaw crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

4. The components of the tracked jaw mobile crushing station include: a sturdy frame, an jaw crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

5. The components of the tracked construction waste mobile crushing station include: construction waste dedicated crusher, vibrating screen, conveyor, etc.

The crawler mobile crushing station integrates the process equipment such as material receiving, crushing and conveying, with advanced design, excellent performance, high production efficiency, convenient use and maintenance, economic operating costs, stable and reliable work. Compared with various fixed crushing stations, the mobile crushing station is like a movable small and medium-sized crushing processing plant, and its working efficiency and operating costs are superior to those of the same or higher level fixed crushing stations. Crawler mobile crushing stations are widely used in many fields: crushing construction waste, crushing materials such as rocks, ores, and block shaped old asphalt concrete for roads.

The main crushers used in tracked mobile crushing stations are jaw crushers and impact crushers. Tracked mobile crushing stations can be divided into four series - cone crushing tracked mobile crushing stations, jaw crushing tracked mobile crushing stations, and impact crushing tracked mobile crushing stations.

b. Characteristics of tracked mobile crushing station:

1. Crawler type mobile crushing station products are lightweight, small in size, and particularly suitable for working in narrow fields;

2. Convenient transportation, tracked walking, no damage to the road surface, equipped with multifunctional accessories, wide adaptability range;

3. By integrating process equipment such as material receiving, crushing, and conveying, and optimizing the process flow, it has excellent performance in rock crushing, aggregate production, and open-pit mining crushing operations. Through the combination of different machine models, a powerful crushing operation line can be formed to complete multi demand processing operations;

4. The whole machine adopts all wheel drive, which can achieve stationary steering. It is equipped with standard configuration and quick change device, with complete safety protection function, especially suitable for narrow and complex areas;

5. Save fuel, with a fuel saving rate of up to 25%;

6. Random Attached Power Group - Optimal Design;

7. It can perform climbing operations to meet the crushing requirements of mining, hydropower stations, coal mines, and other engineering projects.

c. Purpose of tracked mobile crushing station:

1. Mobile screening and crushing equipment with multifunctional operation characteristics;

2. The coarse crushing of hard materials in mining sites widely used in the mining, coal mining, and cement industries;

3. Recycling and reusing construction waste, earthwork engineering, urban infrastructure, roads or construction sites, and other site operations;

4. Processing topsoil and various other materials; Separate viscous concrete aggregates; Construction and blasting industry; Screening after crushing; Quarry industry.

5. Stripping crushing for cement concrete road reconstruction and crushing before asphalt concrete material regeneration.

d. Introduction to Zhongcheng tracked mobile crushing station

Zhongcheng Machinery's tracked mobile crushing station is a tracked hydraulic driven crushing and screening equipment developed by our company based on our own mechanical technology and combined with domestic practical needs. This equipment utilizes an advanced hydraulic system to enable the tracks to move steadily, thus adapting to various complex working site conditions. It has the following advantages:

1. Strong power, as stable as a rock: Enriched with high-power walking motors, powerful horsepower ensures stable production, reliable operation, easy and powerful operation and maintenance.

2. Quiet and energy-saving, environmental protection: Using well-known brand motors, leading the power system to perform outstandingly, with low noise, reduced energy consumption, and environmental friendliness all under control.

e. Composition of tire type mobile crushing station

Tire type mobile crushing stations can be further divided into main series according to their specific working methods, such as counterattack type mobile crushing stations, vertical impact type mobile crushing stations, cone type mobile crushing stations, jaw type mobile crushing stations, and construction waste mobile crushing stations.

1. The components of the counterattack mobile crushing station include: a sturdy frame, an E-type crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

2. The components of the vertical impact mobile crushing station include: a sturdy frame, an jaw crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

3. Components of the cone moving crushing station: including a sturdy frame, cone crusher, feeder, vibrating screen, conveyor belt, motor, and control box.

4. The components of the jaw type mobile crushing station include: a sturdy frame, an jaw type crusher, a feeder, a vibrating screen, a conveyor belt, an electric motor, and a control box.

5. The components of the construction waste mobile crushing station include: specialized crushers for construction waste, vibrating screens, conveyors, etc.

D. Installation and testing of mobile crushing station

1. The equipment should be installed on a horizontal concrete foundation and fixed with anchor bolts.

2. During installation, attention should be paid to the verticality between the main body and the horizontal.

3. After installation, check whether the bolts in each part are loose and whether the main engine compartment door is tightened. If so, please tighten it.

4. Configure power cords and control switches according to the power of the equipment.

5. After the inspection is completed, conduct a no-load test run. If the test run is normal, production can proceed.

E. Maintenance and upkeep of mobile crushing stations:

1. The maintenance and upkeep of machines is an extremely important and regular task, which should be closely coordinated with the operation and maintenance. There should be dedicated personnel on duty to conduct inspections.

2. Mobile crushing stations should be lubricated as required, and small and medium-sized equipment should be regularly lubricated with grease and lubricating oil. In large equipment, if cone and large jaw crushers are used, there is generally a forced lubrication system. At this point, it is important to regularly observe parameters such as oil temperature, oil pressure, and flow rate. Tighten loose fasteners.

During the operation of the mobile crushing station, it is important to regularly pay attention to the noise and vibration of the equipment. If there is excessive noise or vibration, the machine should be stopped quickly for inspection. After troubleshooting, the no-load restart should be carried out in the order of starting.

During the operation of the mobile crushing station, attention should also be paid to observing the quality and yield of the products. When the quality and yield are abnormal, faults such as blockage of the crusher and screening machine or damage to the screening surface may occur. In order to maintain good performance of the mobile crushing station, in addition to normal maintenance, the equipment also needs to undergo minor, medium, and major repairs according to the plan.

The maintenance plan for the mobile crushing station is proposed based on the inspection requirements of each part of the machinery used. Due to differences in maintenance plans among different machines, some machines can be replaced for maintenance when conditions permit. This can reduce downtime for maintenance and improve equipment utilization.

6. Bearings bear all the loads of the machine, so good lubrication is closely related to the service life of the bearings, which directly affects the service life and operating rate of the machine. Therefore, it is required that the lubricating oil injected must be clean and the seal must be good. The main oil injection points are (1) rotating bearings, (2) rolling mill bearings, (3) all gears, and (4) movable bearings and sliding surfaces.

7. Newly installed wheels are prone to loosening and must be checked regularly.

8. Pay attention to whether the various parts of the machine are working properly.

9. Pay attention to checking the degree of wear of easily worn parts and replace worn parts at any time.

10. When placing the base frame of the movable device, dust and other objects should be removed to prevent the movable bearings from moving on the base frame when the machine encounters materials that cannot be broken, resulting in serious accidents.

11. If the bearing oil temperature rises, the vehicle should be stopped immediately to check the cause and eliminate it.

If there is any impact sound during the operation of the rotating gear, it should be stopped immediately for inspection and eliminated.

Overview: In practical applications, mobile crushing stations have demonstrated excellent crushing effects and stability performance. It can not only quickly crush large materials into the required particle size, but also effectively reduce dust pollution and protect the environment. In addition, the maintenance cost of mobile crushing stations is relatively low, with a long service life, bringing considerable economic benefits to users. Mobile crushing stations are playing an increasingly important role in the field of engineering due to their high efficiency, flexibility, and environmental friendliness. With the continuous advancement of technology, the performance of mobile crushing stations will be further improved, providing better crushing services for engineering construction.

Save Time! Get A Detailed Quotation Quickly.