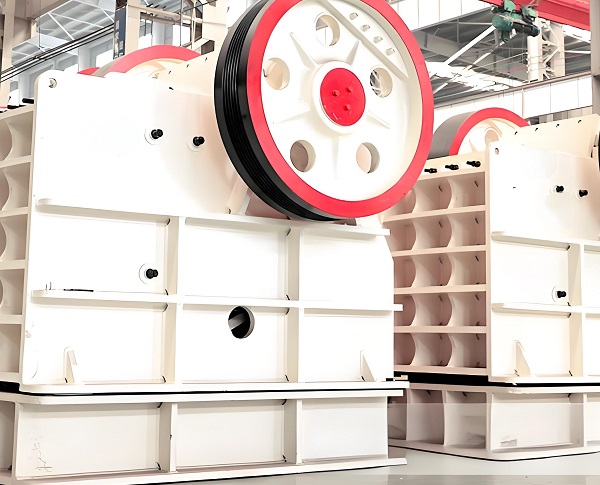

Preface: Jaw crusher is a commonly used crushing equipment. It has the characteristics of high crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance, and economical operating costs. Jaw crushing is mainly composed of a machine base (casing), eccentric shaft, pulley, jaw plate, connecting rod, adjusting mechanism, and locking spring. It completes material crushing operations by simulating the movement of two jaws of animals. Jaw crusher, also known as tiger mouth, consists of two jaw plates, the moving jaw and the stationary jaw, forming a crushing chamber. It simulates the movement of the two jaws of animals to complete material crushing operations. Widely used in the crushing of various types of concrete, ores, and large materials in industries such as construction waste treatment, mining and smelting, and building materials. Suitable for crushing various materials with compressive strength not exceeding 320 megapascals, it is the preferred equipment for primary crushing.

The working part of a jaw crusher consists of two jaw plates. One is a fixed jaw plate (fixed jaw), which is vertically (or slightly inclined at the upper end) fixed on the front wall of the machine body. The other is a movable jaw plate (movable jaw), which is inclined in position and forms a crushing chamber (working chamber) with a larger upper part and a smaller lower part with the fixed jaw plate. The movable jaw plate performs periodic reciprocating motion against the fixed jaw plate, sometimes separating and sometimes approaching. When separated, the material enters the crushing chamber and the finished product is discharged from the lower part; When approaching, the material placed between the two jaw plates is crushed by compression, bending, and splitting.

A. Development status of jaw crusher

The technical level of jaw crusher manufacturers varies greatly, with a few manufacturers' products approaching the world's advanced level, while most manufacturers' products have a significant gap compared to the world's advanced level. The frame of the jaw crusher accounts for a large proportion of the total weight of the machine. Foreign jaw crushers all use welded frames, and even the moving jaw adopts welded structures. The development direction of jaw crushers is to adopt welded frames. There are many examples of unreasonable design of jaw crusher frame structure, which is due to the failure to arrange reinforcement ribs according to the actual stress situation of the crusher

With the emergence of impact resistant large rolling bearings, there is a trend worldwide to use compound pendulum jaw crushers instead of simple pendulum crushers. This is because under comparable conditions, the former has a 30% increase in production capacity compared to the latter; When the production capacity of the two is the same, the former reduces weight by 20% to 30% compared to the latter. However, there are still some problems in the structure of the compound pendulum jaw crusher that need to be studied and improved.

In recent years, due to the improvement of materials for large rolling bearings and the need for underground coarse crushing equipment, there has been a trend towards the development of large swing jaw crushers. With the increasing size of equipment specifications, new mechanisms are inevitably required for the adjustment and safety devices of jaw crushers. Therefore, another trend in the development of jaw crushers is the use of hydraulic adjustment mechanisms for the size of the discharge port, which is not only simple and fast, but can also be adjusted as needed at any time during operation; At the same time, the overload safety device of the machine also uses a hydraulic mechanism to achieve safety and reliability, without damaging the thrust plate, and after troubleshooting, the machine immediately resumes operation. The world is vigorously developing this hydraulic jaw crusher. Production practice has proven that the safety mechanism and adjustment mechanism of hydraulic jaw crushers have achieved the goal of safety and convenient adjustment, and the situation is good, which is highly welcomed by workers on the job.

In terms of improving the crushing efficiency of jaw crushers, in addition to making local improvements to the original equipment structure, such as increasing the height of the crushing chamber and improving production capacity; Reduce the size of the ore discharge outlet and increase the crushing ratio; In addition to increasing the swing speed of the moving jaw to improve equipment production capacity and product quality, countries are currently researching and testing new structures of crushers, such as impact jaw crushers, double moving jaw crushers, and hydraulic transmission jaw crushers.

Jaw crushers are mainly used as coarse and medium crushers in construction waste treatment, mining, building materials, infrastructure and other departments. According to the width of the feeding port, it can be divided into three types: large, medium, and small. Machines with a feeding port width greater than 600mm are considered large machines, machines with a feeding port width between 300-600mm are considered medium machines, and machines with a feeding port width less than 300MM are considered small machines. Jaw crusher has a simple structure, easy manufacturing, and reliable operation.

B. Classification of jaw crushers:

Jaw crushers can be classified according to different standards, and the following are several common classification methods:

a. Classified by swing mode

1. Simple swing jaw crusher (simple swing jaw crusher): During operation, the moving jaw only makes simple circular arc swings. This type of crusher has a simple motion trajectory and low crushing efficiency, but its structure is relatively simple and easy to maintain.

2. Complex swing jaw crusher (compound swing jaw crusher): The moving jaw moves up and down while swinging in a circular arc. This type of crusher has a high crushing efficiency and is suitable for crushing materials of various hardness.

3. Combination swing jaw crusher: Combining the characteristics of simple swing and complex swing, it has higher flexibility and adaptability.

b. Classified by feed inlet width

1. Large jaw crusher: The feed inlet width is greater than 600 millimeters, suitable for large-scale and high-yield crushing operations.

2. Medium sized jaw crusher: The feed inlet width is between 300 and 600 millimeters, suitable for medium-sized crushing operations.

3. Small jaw crusher: The feed inlet width is less than 300 millimeters, suitable for crushing operations in small-scale or laboratory settings.

c. Classified by structural characteristics

1. Double elbow jaw crusher: With two elbow plates, the structure is more stable and suitable for crushing materials with high hardness.

2. Single elbow jaw crusher: With only one elbow, the structure is relatively simple, but it can still meet the needs of general crushing operations.

d. Classified by driving method

1. Electric motor driven jaw crusher: The belt and pulley are driven by the electric motor, which drives the eccentric shaft to move the moving jaw up and down. This is currently the most commonly used driving method.

2. Hydraulic driven jaw crusher: Using a hydraulic system to drive the moving jaw for crushing operations, it has higher flexibility and controllability.

e. Classified by purpose

1. Rough jaw crusher: mainly used for the initial crushing of large materials, crushing them into smaller blocks.

2. Medium sized jaw crusher: used to further crush materials that have already been roughly crushed into smaller particles.

In summary, there are various classification methods for jaw crushers, and users can choose the appropriate type based on their actual needs and operating conditions.

C. Introduction to Zhongcheng Machinery's E-breaking Machine:

Zhongcheng Machinery specializes in producing various types of concrete crushers, stone crushers, stone crushers, and crushing equipment. We provide complete sets of crusher production lines with a daily processing capacity of 15-5000 tons, and offer free wiring services to our customers. Welcome to visit and inspect!

The jaw crusher can meet the requirements of users to work continuously day and night during the service period, but ultimately requires some maintenance. Due to the use of cast steel components, the crusher can still be economically repaired and repaired after many years of operation. The same repair for other architectures of crushers will incur huge costs, and may even be impossible to repair. Modular, weldless frame 1. Structure 1. Ensure excellent durability: The sturdy jaw assembly ensures maximum reliability even in the most difficult crushing conditions.

2. Whole cast steel bearing box. The integral cast steel bearing box can ensure a complete fit with the crusher frame and avoid unnecessary loads on the bearing frame, which were inevitable in the previous two-piece bearing box structure.

3. Durable moving jaw assembly: Made of high-quality cast steel components and driven by two large cast steel or cast iron flywheels. In addition, the forged heavy-duty eccentric shaft with four equally sized large spherical rolling bearings gives the C-type jaw crusher extraordinary reliability. The labyrinth seal protection prevents the lubricating grease of the bearing from being contaminated.

Jaw crusher is a primary crushing equipment with excellent performance. Compared to traditional jaw crushers, it occupies less space, has a larger crushing ratio, operates more smoothly, and has more advantages in transportation, installation, maintenance, and adjustment. Especially suitable for fixed crushing production lines and mobile crushing stations.

The meticulous design and improved structure of the jaw crusher result in better operational performance, endowing the equipment with the following advantages and bringing greater value to users.

In summary, the jaw crusher plays an irreplaceable role in the field of crushing due to its unique working principle and significant advantages. With the continuous advancement of technology and the continuous development of the market, jaw crushers are moving towards higher efficiency, energy conservation, environmental protection, and intelligence. In the future, jaw crushers will pay more attention to equipment durability and maintenance convenience, while incorporating more new technologies such as automation and remote monitoring to improve equipment efficiency and safety.

Save Time! Get A Detailed Quotation Quickly.