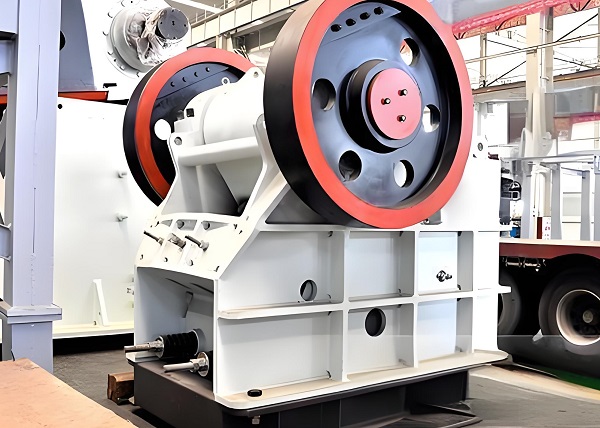

Crusher is a commonly used crushing machinery in the process of garbage disposal and mining production. There are various types of crushers, including jaw crushers, gyratory crushers, cone crushers, roller crushers, hammer crushers, and impact crushers. These devices are widely used in various fields such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries. They have the characteristics of high crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance, and economical operating costs.

Crushers play a crucial role in various industrial fields, especially in construction waste treatment, mining, metallurgy, building materials, and other fields. They are designed to reduce construction waste concrete, large rocks, or ores into smaller, more manageable particles. The following are the advantages and characteristics of crushers:

A. Characteristics of crusher

1. High production capacity: crushers, especially cone crushers, can efficiently process large amounts of materials. Advanced models, such as the SMH series hydraulic cone crusher, have significantly increased production compared to traditional crushers.

2. Uniform particle size of the product: The crusher can produce materials with uniform particle size, which is crucial for many industrial applications. Hydraulic cone crushers are particularly renowned for their ability to produce uniformly sized particles.

3. Low energy consumption: Modern crusher designs focus on energy efficiency, reducing energy consumption and operating costs. The unit energy consumption of cone crusher is relatively low, making it a cost-effective choice.

4. Stable operation: The crusher has been carefully designed to withstand the harsh conditions of continuous operation, ensuring reliability and stability. Advanced design includes features that enhance durability and reduce maintenance requirements.

5. Multifunctionality: The crusher can crush various materials, including hard ores, rocks, and brittle materials. They are used in multiple industries such as metallurgy, power, chemical, transportation, and building materials.

6. Adjustable output: The cone crusher has adjustable settings that can control the particle size of the crushed material. This adjustability allows flexibility to meet different industrial requirements.

7. Durability and Wear Resistance: The cone crusher is made of durable materials that can withstand continuous wear and tear during operation. The surface wear of the moving cone is uniform, ensuring long-term performance and reliability.

In summary, crushers, especially cone crushers, combine advantages such as high production capacity, uniform product particle size, low energy consumption, stable operation, and multifunctionality. These advantages and characteristics make them indispensable equipment in various industrial fields.

B. The development trend of crushers mainly presents the following directions:

1. Large scale, universal, and systematic: With the development of the economy, the demand for large equipment in various fields has increased, and crushers are also developing towards large-scale direction to improve production efficiency and meet the demand for low input and high output. At the same time, crushers are also developing towards universality and systematization to meet the needs of different fields and complex working conditions.

2. Energy conservation and environmental protection: Energy conservation and consumption reduction have become important standards for industrial development, and crusher design also pays more attention to energy conservation and environmental protection.

The new crusher meets the requirements of green production by improving its design, reducing energy consumption and emissions, and increasing energy efficiency.

3. Intelligence and automation: With the development of computer information technology, crushers have also integrated new technologies to achieve intelligent and automated production. The application of technologies such as intelligent sorting systems and automatic feeding devices reduces manual intervention, improves equipment efficiency and sorting accuracy.

4. Multifunctionality: Crushers are developing towards multifunctionality to meet the needs of different materials and processes. By adjusting equipment parameters and configurations, the crusher can handle multiple types of materials and achieve multi-purpose use.

In summary, the development trend of crushers is towards large-scale, universal, systematic, energy-saving, environmentally friendly, intelligent, and multifunctional. These trends will drive continuous innovation and development in the crusher industry, providing more efficient, environmentally friendly, and intelligent crushing solutions for various fields.

As an indispensable key equipment in the fields of construction waste treatment, mining, building materials, transportation, etc., crushers play an important role in breaking large materials into small pieces or powders. With the advancement of technology, crushers are developing towards large-scale, high-efficiency, and intelligent directions. This not only improves crushing efficiency and product particle size uniformity, but also emphasizes energy conservation and environmental protection, reducing energy consumption and emissions. At the same time, the application of automation, remote monitoring and other technologies in crushers further enhances the safety and operational convenience of the equipment. In the future, crushers will continue to integrate new technologies, optimize performance, and improve durability to better serve the development of various fields and meet society's demand for efficient, environmentally friendly, and intelligent crushing equipment.

Save Time! Get A Detailed Quotation Quickly.