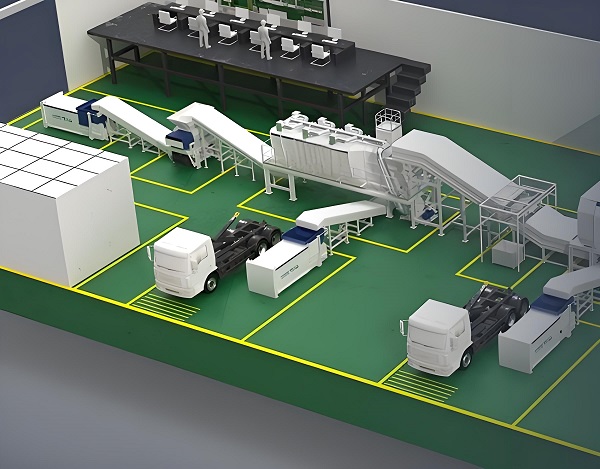

The production line of domestic waste recycling and treatment is a complex and fine system, aiming at efficiently and environmentally treating urban domestic waste and realizing the maximum recycling of resources and the minimum environmental pollution. Through a series of advanced equipment and technologies, the production line converts wastes into valuable resources or performs innocent treatment. The following are the main equipment composition and functions of the domestic waste recycling and treatment production line:

A. Composition of receiving equipment:

Garbage collector: used to collect household garbage from all corners of the city.

Garbage dumping platform: provide garbage dumping place for garbage collector, and have basic weighing and recording functions.

Function: The receiving equipment is the starting point of the production line, responsible for collecting and transporting the garbage from the source to the treatment plant, and providing raw materials for subsequent treatment.

B. Composition of pretreatment equipment:

Crusher: used to crush large pieces of garbage into small pieces for subsequent sorting and treatment.

Compressor: It compresses garbage to reduce volume and facilitate storage and transportation.

Deodorization equipment: remove the odor generated by garbage by spraying deodorant or adopting biodeodorization technology.

Function: the pre-treatment equipment converts the waste into a more easily handled form through crushing, compression and deodorization, laying a foundation for subsequent sorting and resource recovery.

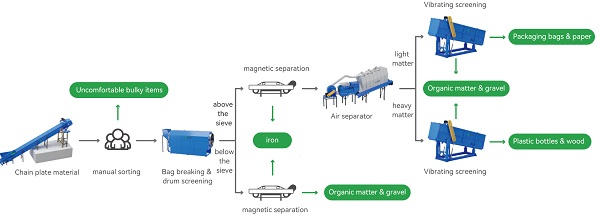

C. Sorting equipment composition:

Magnetic separator: use magnetic force to separate the iron substances in the garbage.

Air Separation Equipment: Light materials (such as plastics and paper) are separated from heavy materials (such as stones and metals) by air flow.

Manual sorting platform: professional personnel shall carry out fine sorting to further separate recyclable materials from non-recyclable materials.

Function: The sorting equipment is the key link of resource recovery. The recyclable materials and non-recyclable materials in the garbage are separated by magnetic separation, air separation and manual sorting, so as to provide convenience for subsequent resource recovery and final treatment.

D. Composition of transmission equipment:

Conveyor belt: it is used to transfer garbage from one place to another and realize continuous operation of production line.

Hoist: It is used to lift garbage from low place to high place for subsequent treatment.

Function: the transmission equipment is used to connect all processing links on the production line, so as to ensure that the garbage can be smoothly and efficiently transmitted to the next processing stage.

E. Composition of resource recovery equipment:

Paper regeneration equipment: convert waste paper into pulp and process into new paper.

Plastic pelletizer: Crush, melt and pelletize waste plastic to form recyclable plastic particles.

Metal crusher: scrap metal is broken into small pieces for subsequent smelting and recycling.

Function: through a series of processing steps, the resource recovery equipment converts recyclable materials in garbage into valuable resources to realize resource reuse and environmental protection.

F. Composition of dust removal equipment:

Bag-type dust collector: remove dust particles in the air through bag filtration.

Electrostatic precipitator: absorb the dust particles in the air on the electrode based on the electrostatic principle.

Function: The dust removal equipment is used to remove the dust pollution generated during the operation of the production line and protect the environment and the health of employees.

G. Composition of packaging equipment:

Packer: package the sorted garbage or recycled materials for storage and transportation.

Function: The packaging equipment compresses and packages the garbage or recycled materials to reduce the volume, facilitate subsequent storage and transportation, and help reduce environmental pollution.

H. Composition of wastewater treatment equipment:

Sedimentation tank: used to remove suspended solids in wastewater.

Bioreactor: remove organics in wastewater by degradation of microorganism.

Filtration equipment: further remove impurities and pollutants from wastewater.

Function: Waste water treatment equipment is used to treat the waste water produced by the production line, remove the harmful substances therein, ensure that the waste water meets the environmental protection standard before discharge, and prevent environmental pollution.

PS: The equipment composition and function of the domestic waste recycling and treatment production line are complex and fine, and each equipment plays an indispensable role. Through reasonable equipment configuration and efficient operation management, waste recycling and environmental protection can be realized, making contributions to the sustainable development of the city.

Save Time! Get A Detailed Quotation Quickly.