The production line of garbage sorting and processing equipment consists of multiple devices, including crushers (bag breakers), drum screens, vibrating screens, bounce screens, slack screens, belt conveyors, air separators, and magnetic separators, which can be flexibly combined according to different needs.

Crusher: Urban household waste is usually packed in plastic bags, and there may be small bags inside the large bags. If the garbage is not dispersed from the bag, the subsequent sorting work cannot be effectively carried out. Therefore, in the initial stage of garbage disposal, it is necessary to break or tear the garbage bags, usually using a bag breaker or crusher. The function of both devices is to tear open the garbage bag for subsequent sorting. However, the difference between them is that the bag breaking machine is mainly used to tear open garbage bags and does not further break the garbage inside the bag into multiple small pieces. The scattered garbage helps to reduce serious entanglement, pollution, and adhesion. In addition to tearing apart garbage bags, crushers can also tear garbage into multiple small pieces, improving the dispersion effect of garbage and effectively avoiding adhesion, entanglement, and pollution problems.

Drum screen, also known as rotary screen, is a slow rotating cylindrical screening equipment. Its axis is usually installed at a tilt angle of 3-5 degrees. During use, the material is fed from the higher end and continuously flipped inside the drum, ultimately separating fine particles through sieve holes. The inclination angle of the drum screen affects the axial movement speed of the material inside the drum, while the movement of the material perpendicular to the drum axis is controlled by the rotational speed. This device is usually used for screening household waste and construction and decoration waste, and the size of the sieve holes can be flexibly adjusted according to actual needs. The drum screen technology is quite mature and can effectively screen garbage of different particle sizes, with high processing capacity.

Bouncing sieve is a device that sorts materials based on their weight, density, shape, and size. Through the bounce screen, materials can be classified into 2 to 3 categories. One type is three-dimensional and heavy objects, such as plastic bottles, stones, ceramics, wood, and metal cans; The other type is flat and lightweight materials such as plastic film, fabric, paper, cardboard boxes, and fiber products. The sieve plate can have additional sieve holes as needed to separate materials smaller than a specific size (such as 60 millimeters). In addition, the bouncing screen can effectively shake the material, remove the sticky substances and sand attached to the material, and thus play a role in dispersing the material.

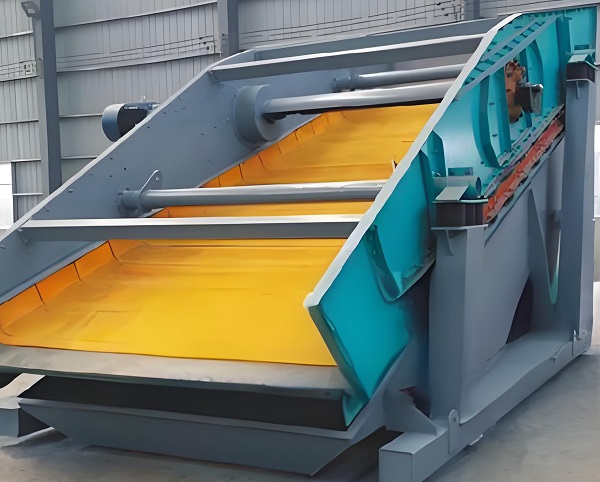

Chi Zhang Screen is a screening equipment that uses a polyurethane mesh chassis, which can adjust the tightness to achieve a trampoline like effect. Its movement is driven by two vibration motors. This elastic screen effectively handles the screening challenges posed by wet and viscous materials. The double vibration motor generates resonance and moves materials in two ways: one is by adjusting the tightness of the polyurethane pad, and the other is by conveying the material. Due to the tight and loose adjustment of the chassis, blind spots and hanging nails are avoided, thereby preventing blockages. High acceleration enables difficult to separate materials to be screened, and the sieve also provides multi-layer design and standard sieve hole combinations.

Why choose Zhongcheng Machinery as the supplier of garbage sorting equipment?

1、 The scheme design adopts the general contracting mode, which saves time and effort, and is reassuring.

Firstly, from site investigation and confirmation, to the selection of production line plans and equipment configuration, to later on-site installation and trial operation, the entire process is tracked and managed by the company's professional personnel. The investment and engineering construction of users are very clear. Users only need to wait for the start of operation, and the entire process is time-saving and worry free.

2、 The technology is mature and the equipment is very reliable.

The production line plan is designed according to specific circumstances, with a compact and reasonable layout of the entire process and smoother operation. At the same time, the quality of all equipment has been guaranteed, and the overall equipment is at an advanced level, ensuring that the production line can operate efficiently and stably for a long time.

3、 Green environmental protection, energy conservation and emission reduction.

The design of the garbage sorting equipment production line meets the domestic environmental assessment standards, and the noise and dust pollution of the entire production line during operation have been effectively controlled without affecting the surrounding environment. This not only improves the economic benefits of the enterprise, but also takes into account social benefits.

Save Time! Get A Detailed Quotation Quickly.