Preface: The maintenance and daily maintenance of the vibrating screen are important measures to ensure its efficient and stable operation. The following introduces the maintenance and daily maintenance of the vibrating screen:

A. Maintenance of the vibrating screen

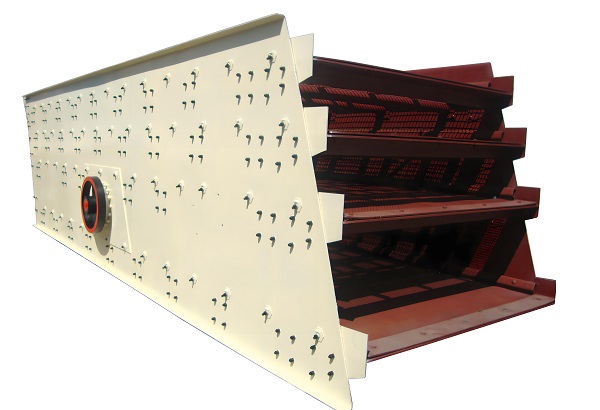

Vibrating Screen

a. Poor screening effect

1. Inspection and adjustment: First check whether the screen hole is blocked and whether the screen surface is damaged. If there is a problem, the screen surface should be cleaned or replaced in time. At the same time, check whether the screen is fixed tightly. If it is loose, tighten the screen. In addition, it is necessary to check whether the screening feeding is uniform. If the feeding is uneven, the feeding amount or feeding method needs to be adjusted.

2. Adjust the inclination and transmission: If the screening effect is not good, you can also try to adjust the inclination of the screen box to improve the movement trajectory of the material on the screen surface. At the same time, check whether the transmission belt is too loose. If it is too loose, tighten the transmission belt.

b. Bearing heating

1. Inspection and lubrication: Bearing heating may be caused by lack of oil, inconsistent oil quality or excessive oil filling. At this time, the lubrication of the bearing should be checked. If there is no oil, it is necessary to add oil in time; if the oil quality is not up to standard, it is necessary to replace the appropriate lubricant; if the oil is overfilled, some of the lubricant needs to be properly released.

2. Cleaning and replacement: If the bearing is hot and accompanied by abnormal sound, it may be caused by bearing wear or dirt. At this time, the bearing should be cleaned and the seal ring should be replaced to check whether the sealing device is intact. If the bearing is severely worn, a new bearing needs to be replaced.

c. Vibrator failure

1. Inspection and replacement: The vibrator is one of the key components of the vibrating screen. If a fault occurs, it should be repaired in time. The inspection content includes checking whether the eccentric block of the vibrator is installed correctly and whether the bearing is worn. If there is a problem, the position of the eccentric block needs to be adjusted in time or a new bearing needs to be replaced.

2. Cleaning and lubrication: The thickening and agglomeration of the grease in the vibrator will also affect its normal operation. At this time, the vibrator should be cleaned and updated with appropriate grease.

d. Other faults

1. Motor damage: If the vibrating screen cannot start or the amplitude is small, it may be caused by motor damage. At this time, check whether the motor is damaged and replace it with a new motor.

2. Control circuit failure: If the vibrating screen cannot start or runs unstably, it is also necessary to check whether the electrical components in the control circuit are damaged and replace the damaged electrical components.

B. Daily maintenance of the vibrating screen

Vibrating Screen

a. Inspection before starting

1. Screen inspection: Check whether the screen is damaged, loose or blocked. If there is a problem, it should be replaced or cleaned in time.

2. Bolt tightening: Check whether the bolts in each part are tightened. If they are loose, they need to be tightened in time to prevent the equipment from malfunctioning during operation.

3. Motor wiring: Check whether the wiring of the vibration motor is correct and whether the grounding is good to ensure that the motor can operate normally and safely and reliably.

4. Feed and discharge port: Check whether the feed and discharge ports are unobstructed. If blocked, they need to be cleaned in time to ensure the material conveying efficiency.

b. Precautions during operation

1. Observe the operation status: During the operation of the equipment, pay attention to whether the parameters such as vibration amplitude, screening effect, motor temperature, etc. are normal. If abnormal conditions are found, stop the machine immediately for inspection.

2. Control the feed amount and speed: Excessive feed amount and too fast feed speed will overload the vibrating screen and affect the screening effect and equipment life. Therefore, the feed amount and feed speed should be reasonably controlled according to the specifications and performance of the equipment.

3. Clean the screen surface regularly: During the operation, a certain amount of materials and impurities will accumulate on the screen surface, affecting the screening effect. Therefore, the screen surface should be cleaned regularly to keep the screen surface clean.

c. Maintenance after shutdown

1. Clean the equipment: After shutdown, clean the screen surface, feed port, discharge port and body of the vibrating screen in time to remove residual materials and impurities.

2. Check the wearing parts: Regularly check the wearing parts of the vibrating screen such as screens, springs, rubber seals, etc. If damaged, they should be replaced in time.

3. Lubrication and maintenance: Lubricate and maintain all parts of the vibrating screen to extend the service life of the equipment. Select the appropriate lubricant and lubrication method according to the equipment's instruction manual.

4. Protective measures: During the equipment shutdown period, protective measures should be taken to prevent the equipment from being affected by the external environment. The equipment can be covered and rust-proofed.

PS: The repair and daily maintenance of the vibrating screen must be carried out in accordance with the specifications to ensure its normal operation and extend its service life. During the repair process, corresponding repair measures should be taken for different types of faults; during the daily maintenance process, attention should be paid to the inspection before starting, precautions during operation, and maintenance after shutdown.

Save Time! Get A Detailed Quotation Quickly.