Preface: The installation and maintenance of the vibrating screen is an important part to ensure its efficient and stable operation. The following are the installation and maintenance steps and precautions of the vibrating screen:

A. Installation steps of the vibrating screen:

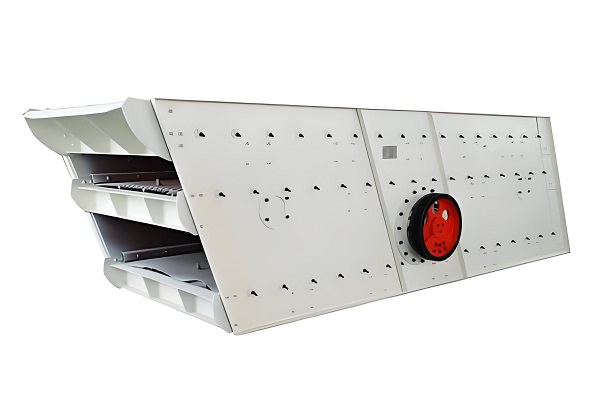

Vibrating Screen

1. Remove the transport support: Since the base and the screen frame of the screen machine are connected by springs, the upper half of the screen machine needs to be fixed with a transport support during transportation. After entering the installation site, this support should be removed.

2. Ensure a horizontal foundation: Place the screen machine on a horizontal ground. If it is not possible to lay a foundation, a vibration-proof rubber sheet can be laid between the workbench and the machine base.

3. Install the support or hanging device: Shovel the ground flat to prevent problems caused by uneven ground during use. Operate according to the support or hanging drawings and install each component in strict order. Before installing the spring component, the actual stiffness of the end face mark should be matched.

4. Connect the screen box: Connect the screen box to the support or hanging device and adjust it according to the specified inclination angle. For hanging screens, the inclination angle of the screen box and the level of the main axis of the screen box should be adjusted at the same time. Generally, the horizontal level is adjusted first to eliminate the deflection of the screen box. After the horizontal correction, the longitudinal inclination of the screen box is adjusted. The vibration isolation spring should be evenly stressed, and the stress condition can be judged by measuring the compression of the spring. Generally, the compression of the two sets of springs at the feeding end must be the same, and the same should be true for the two sets of springs at the discharging end. The spring compression at the discharging end and the feeding end may be different.

6. Install the motor and triangular belt: When installing the motor, its foundation should be leveled and the level of the motor needs to be corrected. The center lines of the corresponding grooves of the two belt wheels should coincide, and the tension requirements of the triangular belt are appropriate.

7. Fix the screen surface: Install and fix the screen surface as required.

8. Check and debug: Check whether the feed and discharge chutes of the screen and the under-screen funnel have collisions during operation. After that, carry out empty car test operation, and the time shall not be less than 8 hours. During this period, observe whether the screen starts smoothly and quickly, whether the vibration and operation are stable, and whether there is no special noise. Observe whether its amplitude meets the requirements through the amplitude card.

9. When the screen is running, the vibration of the screen box should not produce sway. If sway occurs, the reason may be that the height difference of the springs on both sides is too large, the tension of the hanging wire rope is uneven, the rotating shaft is not horizontal, or the triangular tape is too tight, and corresponding adjustments should be made.

10. Within 4 hours of driving, the bearing temperature gradually increases and then remains stable.

11. After driving for 2 to 4 hours, stop the machine to check whether the connecting parts are loose. If they are loose, tighten them before driving.

12. After 8 hours of trial running, if there is no fault, the installation project can be accepted.

13. Wiring safety: The cables in the vibration motor and the screen machine will experience severe vibration, so they must be connected to the standard ground wire to ensure safety.

B. Maintenance of vibrating screen

Vibrating Screen

a. Daily inspection of vibrating screen

1. Remove various debris that hinder the movement of the vibrating screen.

2. Check whether there is enough lubricating oil at each lubrication point of the motor and the vibrating screen transmission mechanism. For grease-lubricated bearings, the oil filling should not exceed two-thirds.

3. Ensure that the screen has sufficient tension and fixing force. Loose or uneven tension of the screen and fluctuation of the screen surface will cause adverse effects and shorten the life of the screen.

4. Check all bolt connection parts to ensure that they are tightened.

5. Check the tension of the vibration screen drive belt to prevent slipping and affect the normal operation of the vibration screen.

6. Check the sealing strip and replace it in time if it is worn or defective.

7. Check whether the connection of the feed box is loose to prevent the gap from becoming larger and causing collision, resulting in equipment rupture.

8. Check whether the wires, fuses and starting devices are normal.

9. Start the vibration screen and run it without load for 2 to 3 minutes to confirm whether the vibration screen is normal and whether the screen has jumping phenomenon.

10. Check the screen support device. If the rubber pad or spring is found to be damaged or over-flattened, replace it in time.

b. Operation inspection of vibration screen

1. Feed the material to the screen surface along the direction of material movement, and try to make the material evenly distributed on the entire screen surface. Overload is not allowed.

2. Check the heating degree of the main bearing. Its maximum allowable temperature rise is generally 45~50℃ higher than the room temperature.

3. Check whether the vibration of the vibrating screen is stable. If there is abnormal vibration, impact or shaking of the fixed frame, it should be stopped in time and adjusted appropriately.

4. The vibrating screen can only stop working after the feeder has finished feeding.

5. After the vibrating screen stops, touch the area near the bearing cover with your hand to check the bearing temperature rise.

6. The parking of the vibrating screen must comply with the process system sequence. Except for special requirements, it is strictly forbidden to continue feeding the screen after stopping with material.

c. Regular maintenance of the vibrating screen

1. The equipment should be refueled frequently during operation. It is recommended to refuel twice a week and use Shell, Avali or RL3 grease for lubrication.

2. Every three months, the equipment should be repaired and maintained, including checking whether the motor and fasteners are loose. At the same time, the vibrator should be disassembled, the bearings and oil seals should be cleaned and checked to ensure that they are in good condition. If severe wear is found, it should be replaced in time.

3. In order to ensure the safe use of the cable, it is recommended to replace the motor lead every three months and conduct regular inspections.

4. The screen is the most easily worn component in the vibrating screen, and its life varies with the structural type. When the screen is damaged, it should be replaced in time. When replacing the screen, loosen the external locking handle, remove the screen grid and screen frame, remove the rubber seal and fastening bolts, replace the new screen, and reinstall it in the opposite order. Pay attention to the flatness and firmness of the screen, and make sure all bolts are tightened.

5. The bearings of the vibrating screen are usually replaced every 8 to 12 months, the drive belt is replaced every 2 to 3 months, the life of the spring is about 3 to 6 months, and the life of the screen frame is two years. Users should check regularly during use, find problems early, and maintain them in time.

PS: The installation and maintenance of the vibrating screen need to be carried out in accordance with the specifications to ensure its normal operation and extend its service life. During the installation process, attention should be paid to the installation sequence and commissioning requirements of each component; during the maintenance process, daily inspections, operation inspections and regular maintenance should be carried out regularly.

Save Time! Get A Detailed Quotation Quickly.